Manufacturing method of heat preservation and decoration integrated plate

A manufacturing method and integrated board technology, which are applied in building construction, covering/lining, construction, etc., can solve the problems of decreased joint strength, low production efficiency and safety of composite adhesives, and achieve improved joint stability and high production efficiency. , the effect of reducing the degree of offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

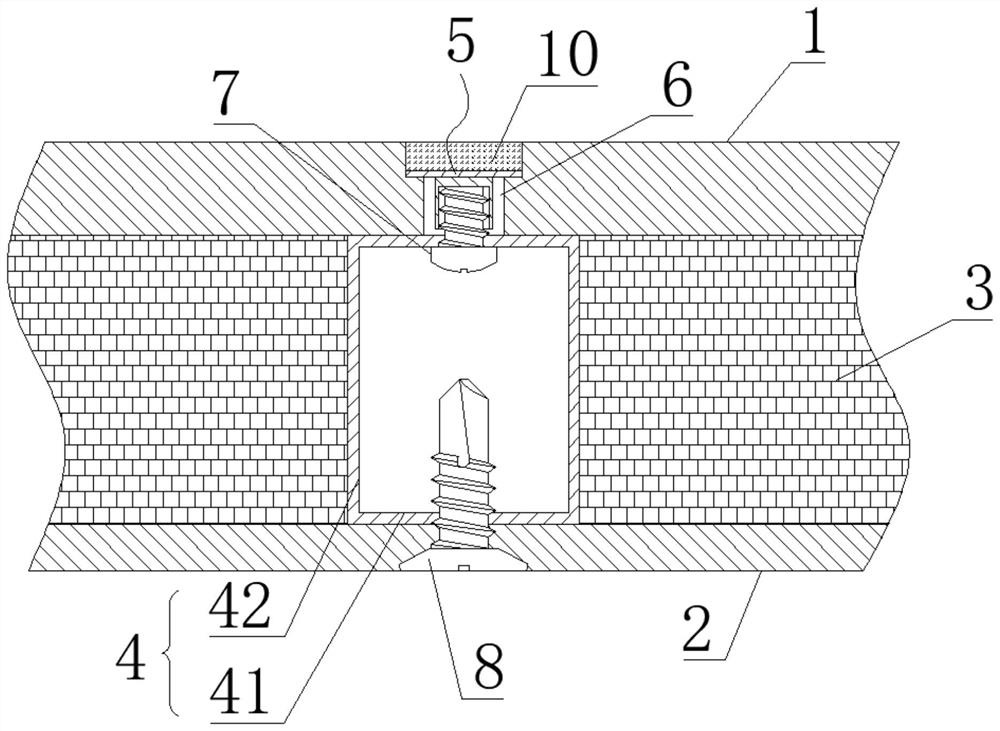

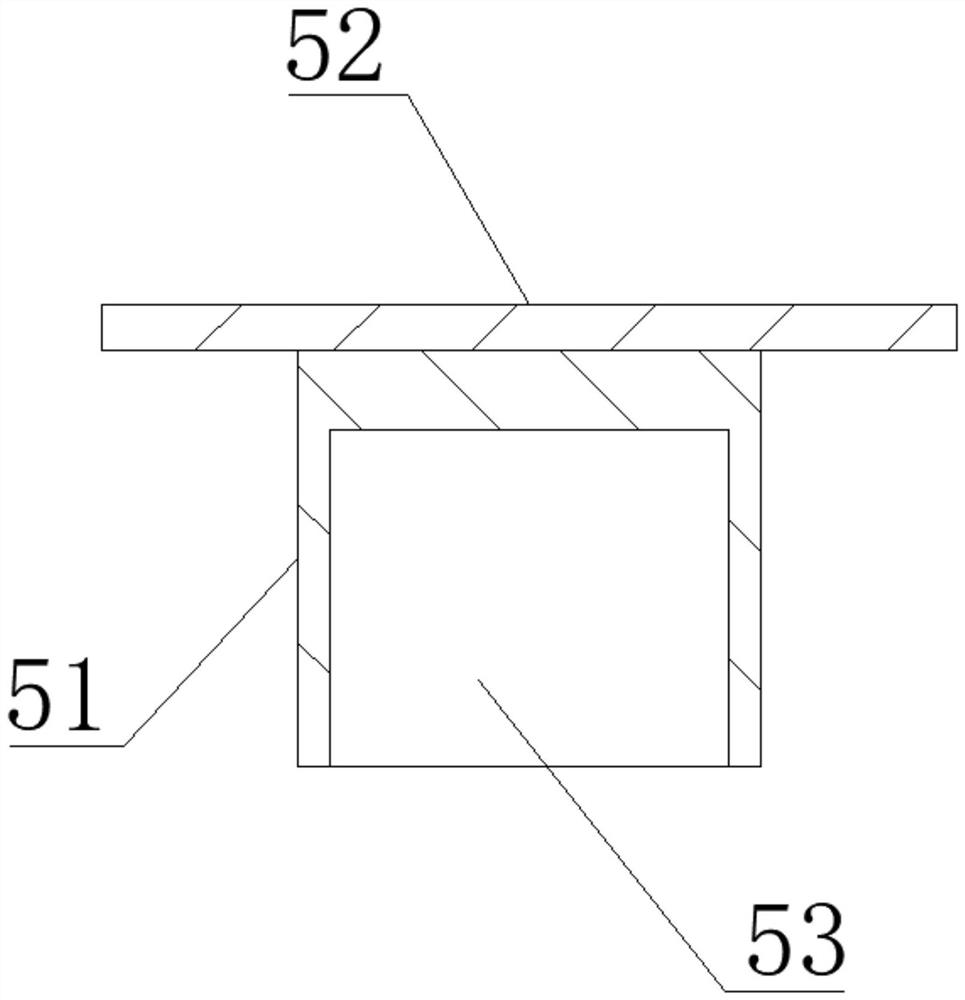

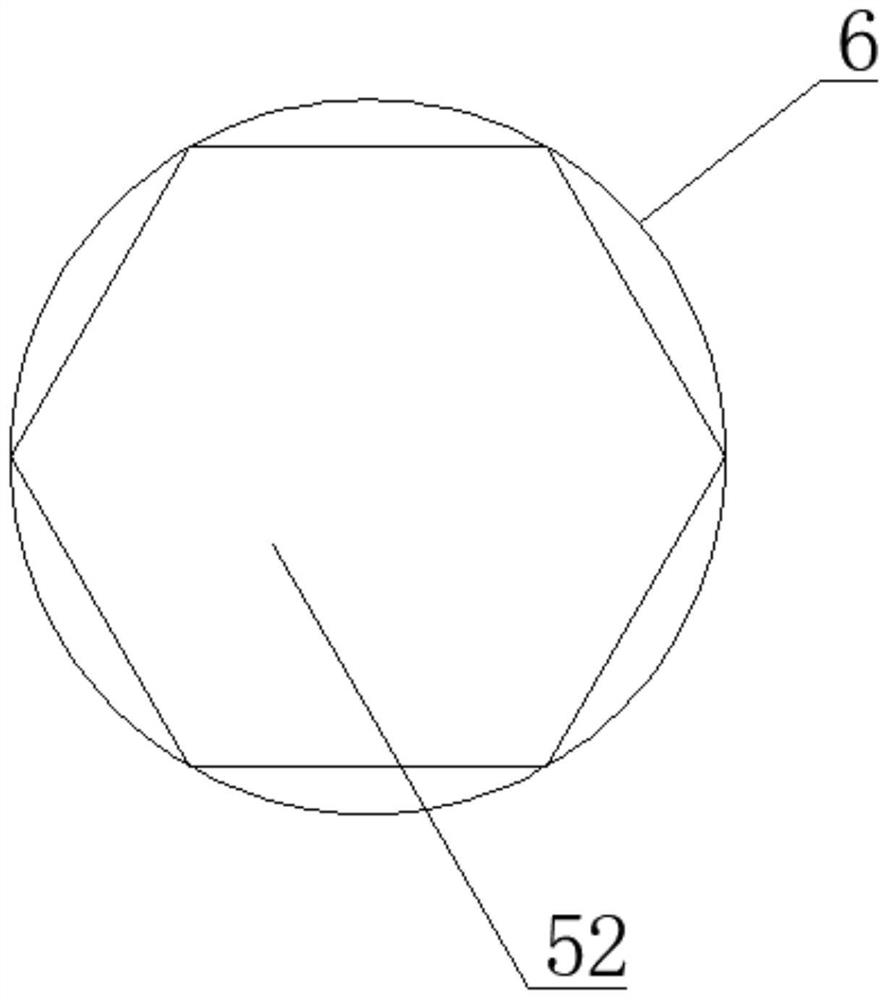

[0045] Such as Figure 1-4 , 11, the manufacturing method of the thermal insulation and decoration integrated panel provided in this embodiment includes a panel 1, a back panel 2, a reinforcement 4, a threaded fastener, and a nut stand 5, and there is a gap between the panel 1 and the back panel 2 Insulation layer 3, the insulation layer 3 in this embodiment is a rock wool insulation layer, specifically rock wool strips, a part of the rock wool strips is reserved with a gap for installing reinforcements 4, and the reinforcements 4 are arranged between the panel 1 and the back panel 2 , the upper side wall and the lower side wall of the reinforcement are provided with a first hole 14, in this embodiment, the first hole of the upper side wall of the reinforcement is a through hole, and the first hole of the lower side wall of the reinforcement is Threaded hole, the panel 1 is provided with a T-shaped perforation 6, the large hole and the small hole of the T-shaped perforation ar...

Embodiment 2

[0062] Such as Figure 5-6 As shown, the difference between this embodiment and Embodiment 1 is:

[0063] The threaded fastener is a long screw 9, and the long screw 9 passes through the second hole, the first hole on the lower side of the reinforcement, and the first hole on the upper side of the reinforcement in sequence, and extends into the nut column 5. In this embodiment, only one long screw 9 is used to cooperate with the nut column 5, and combined with the second hole position, the installation of the reinforcing member 4 can be realized. Similarly, it only needs to be screwed in and locked from the 2 sides of the back plate. The diameters of the two first holes on the reinforcement member in this embodiment are the same.

[0064] When installing, glue the inner surface of the panel first, then arrange the insulation layer and reinforcements on the inner surface of the panel, and align the first hole on the upper side of the reinforcement with the nut column, and the...

Embodiment 3

[0066] Such as Figure 7-8 As shown, the difference between this embodiment and Embodiment 1 is:

[0067] The threaded fastener includes a second cylinder 11, a first external thread 12, and a second external thread 13. The upper end of the second cylinder 11 is provided with the first external thread 12, and the lower end of the second cylinder 11 is provided with the second external thread. The external thread 13, the first external thread 12 of this embodiment passes through the first hole 14 on the upper side of the reinforcement 4 and is threaded with the nut column 5, and the second external thread 13 passes through the second hole and the bottom of the reinforcement in turn. The first hole on the lower side of the reinforcement is threadedly matched with the first hole on the lower side of the reinforcement. The diameter of the first hole on the lower side of the reinforcement is larger than the diameter of the first hole on the upper side of the reinforcement, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com