Capsule feeding mechanism

A transmission mechanism and capsule technology, which is applied in the directions of capsule delivery, drug delivery, and pharmaceutical formulations, can solve problems such as the output limitation of the capsule machine and the development limitation of functions, and achieve the effect of facilitating the filling of capsules, increasing work efficiency and saving space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but these are only exemplary and not intended to limit the scope of protection thereof.

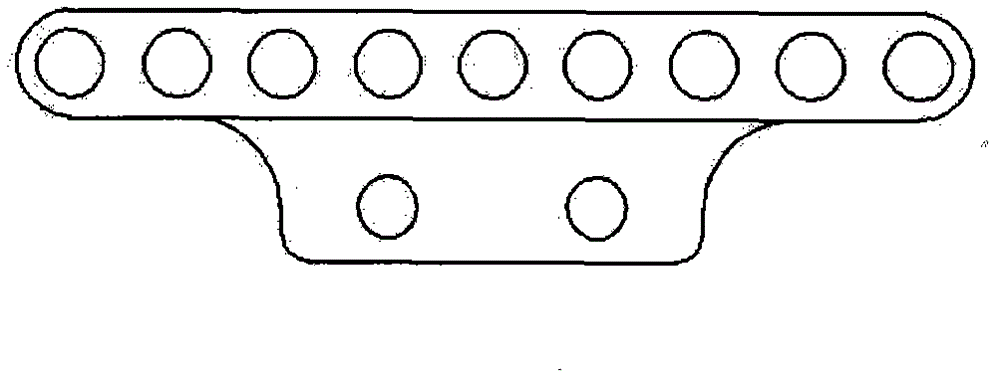

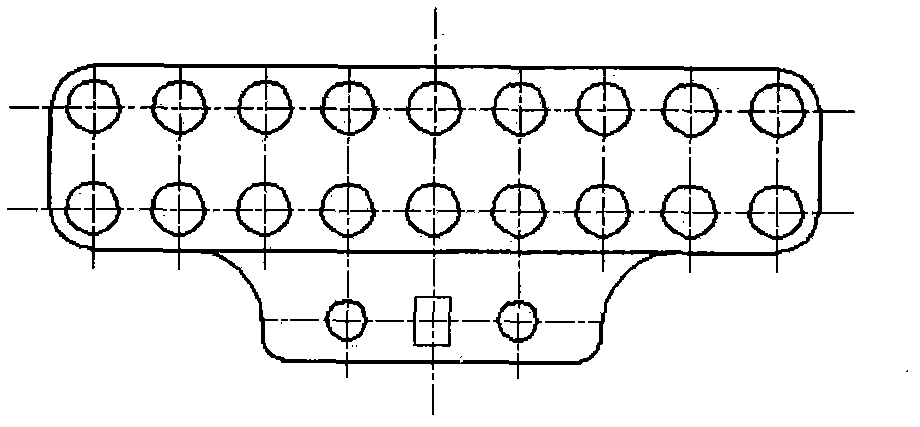

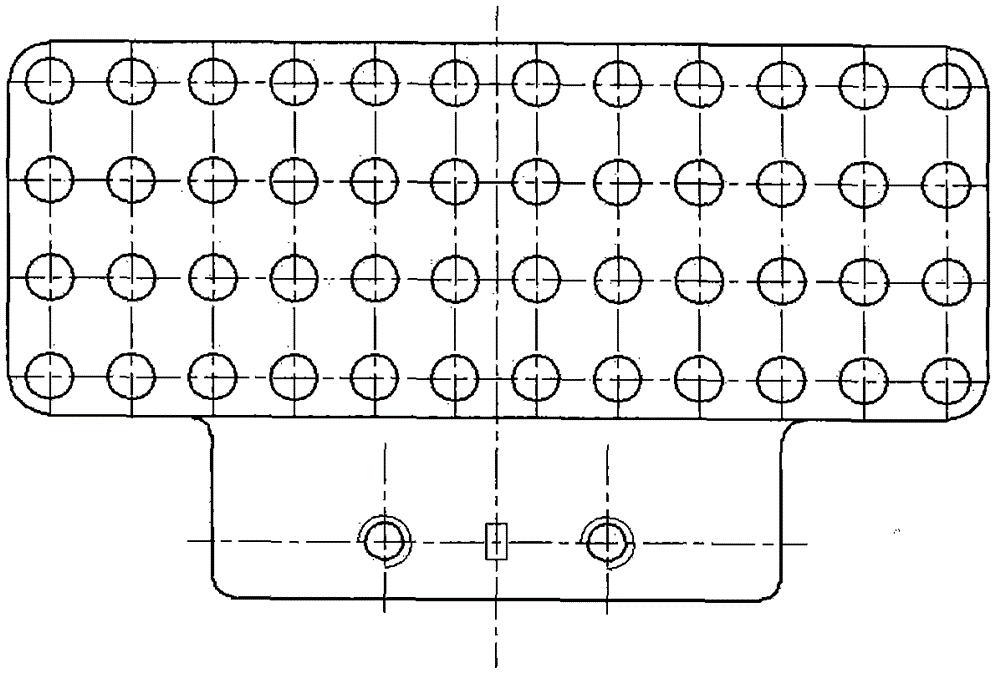

[0023] For a station that exists in the prior art, broadcast a single-row capsule mechanism (see Figure 1-4 ) problem of inefficiency, the inventor has proposed the following one station to sow more than two rows, especially the capsule broadcasting mechanism of two rows of capsules through long-term research. See Figure 5 As shown (two rows are described as an example), the capsule dispensing mechanism includes a lower capsule part, a transmission mechanism part and a capsule hopper part thereof, and the lower capsule part includes more than two rows of sequence forks 3, and the sequence forks 3 are provided with two The vertical channel of the row, the upper part of the vertical channel and the capsule hopper 1 that is fixed on the hopper bracket 19 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com