Press machine device for bending U-shaped round steel fillet hook

A hook device and press technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of large size error, low efficiency, easy deformation, etc., and achieve consistent bending arc, high work efficiency, and good forming. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

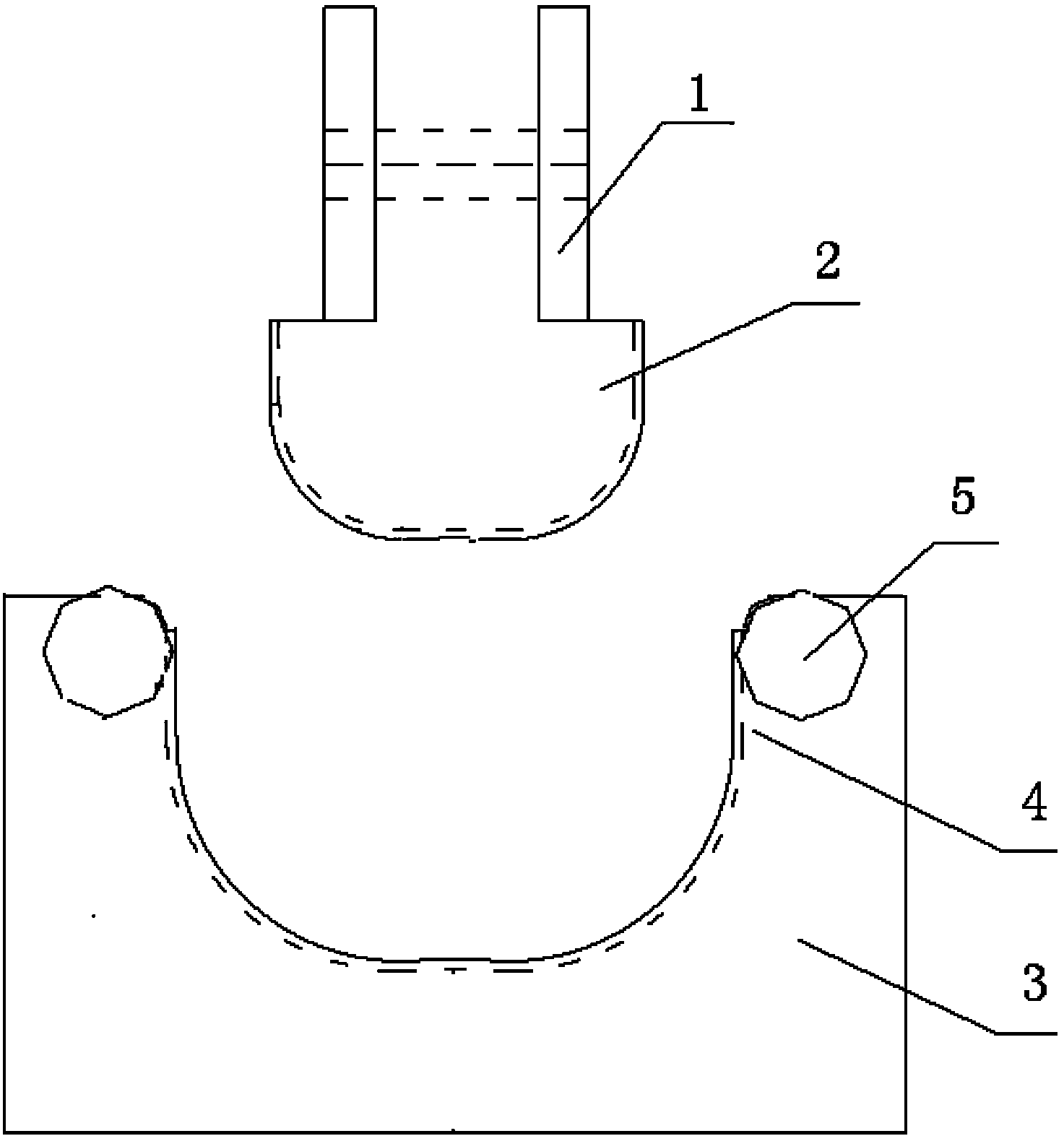

[0013] A U-shaped round steel round corner hook device for a press in this embodiment is as follows: figure 1 As shown, it includes an upper mold and a lower mold, and the upper mold and the lower mold are arranged oppositely; the upper mold includes an upper mold body, and the upper mold body is provided with an inner card shape and a straight U-shaped rounded belt A punch, the upper end of the punch is parallel to the lower end, and the outer side of the punch is provided with an arc-shaped groove of the upper die having the same diameter as the round steel to be bent; the lower die includes a lower die body, and the lower die body A U-shaped support frame matching the punch is arranged on the top, and the two open ends of the U-shaped support frame are provided with lower mold rotating shafts.

[0014] One side of the U-shaped support frame is provided with a size baffle.

[0015] The side of the lower die is provided with a scale for measuring the angle at which the round...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com