A method for manufacturing roll cooling water pipe in multi-wire slitting rolling

A technology of cooling water pipes and split rolling, which is applied in the direction of rolls, metal rolling, metal rolling, etc., can solve problems such as inconsistent bending, unreached rolling volume, roll wear, etc., and achieve stable online service life. The difference and line difference are easy to control, and the wear of the pass is uniform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

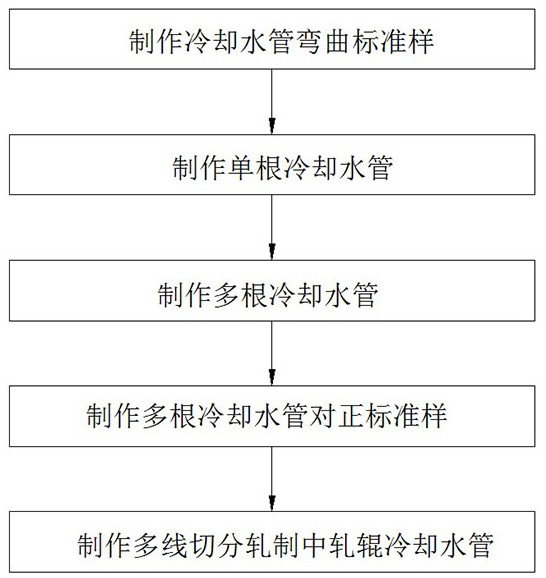

[0018] Embodiment 1: A method for manufacturing roll cooling water pipes in multi-line split rolling, comprising the following steps:

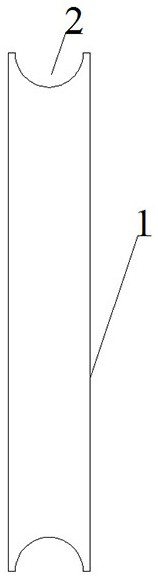

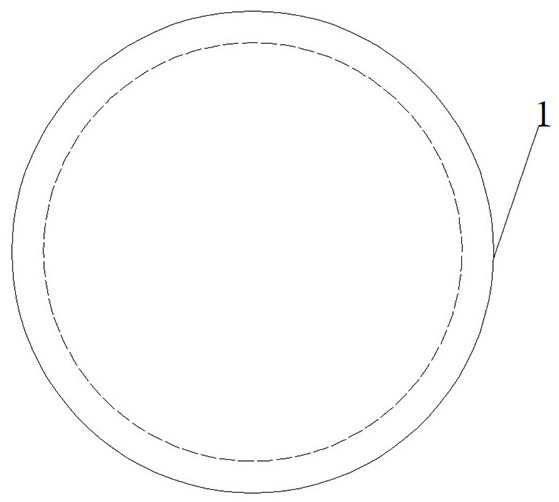

[0019] a. Make cooling water pipe bending standard sample 1: According to the diameter and length of the roll in multi-line slit rolling, make a cooling water pipe bending standard sample 1 with the same curvature as the roll. The structure of cooling water pipe bending standard sample 1 is a cylindrical structure , the outer wall of the cylindrical structure is provided with an annular groove 2, the inner diameter of the annular groove 2 is the same as the diameter of the roll;

[0020] b. Make a single cooling water pipe: heat the processed single cooling water pipe, and then bend it along the cooling water pipe standard sample 1, so that the bending degree of the cooling water pipe is consistent with the roll;

[0021] c, make a plurality of cooling water pipes: repeat step b, make the same cooling water pipes as the number of rolls;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com