Self-adaptive profiling spray machine for orchard

A self-adapting, sprayer technology, applied in the application, capture or killing devices, animal husbandry, etc., can solve problems such as large ground slope drop, different distances, irregularities, etc., to achieve the effect of variable spray volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in further detail now in conjunction with accompanying drawing.

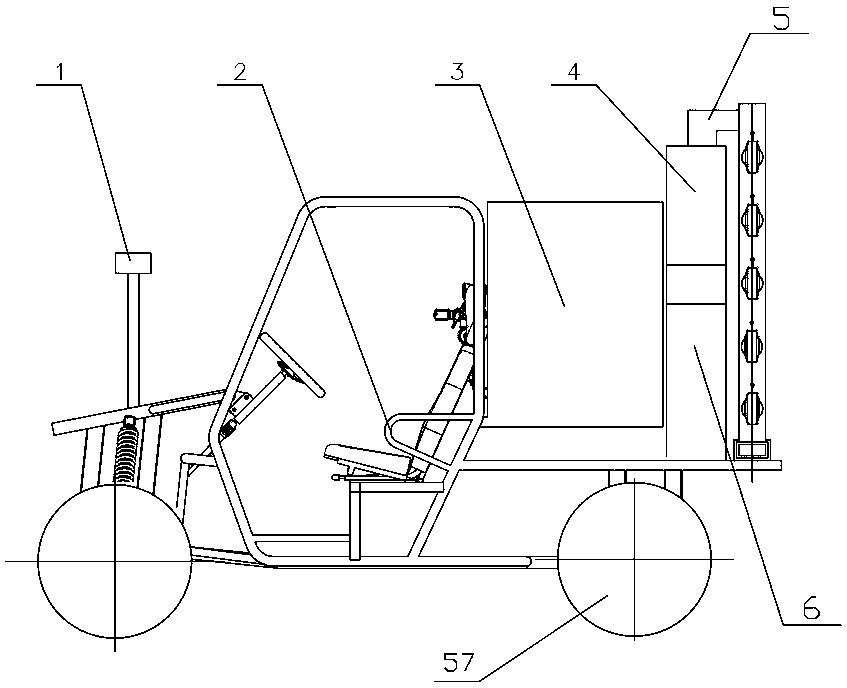

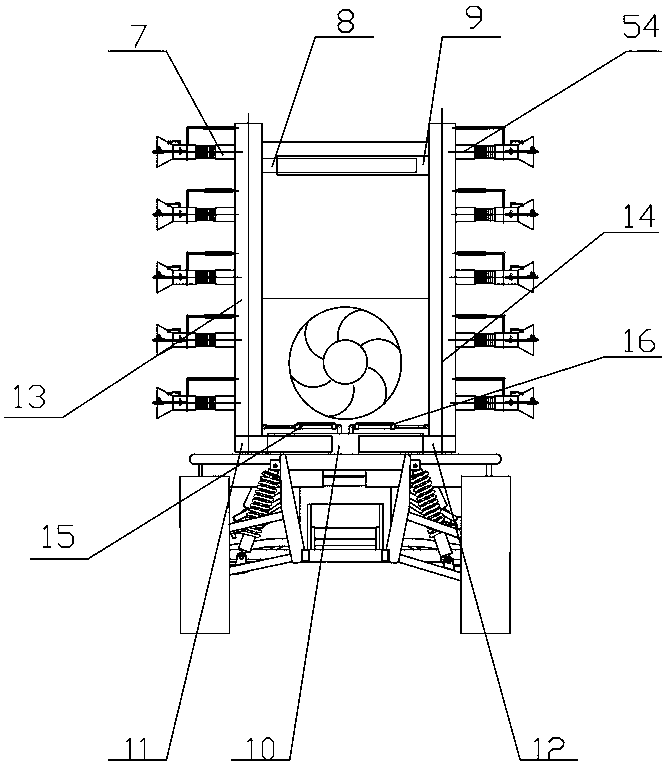

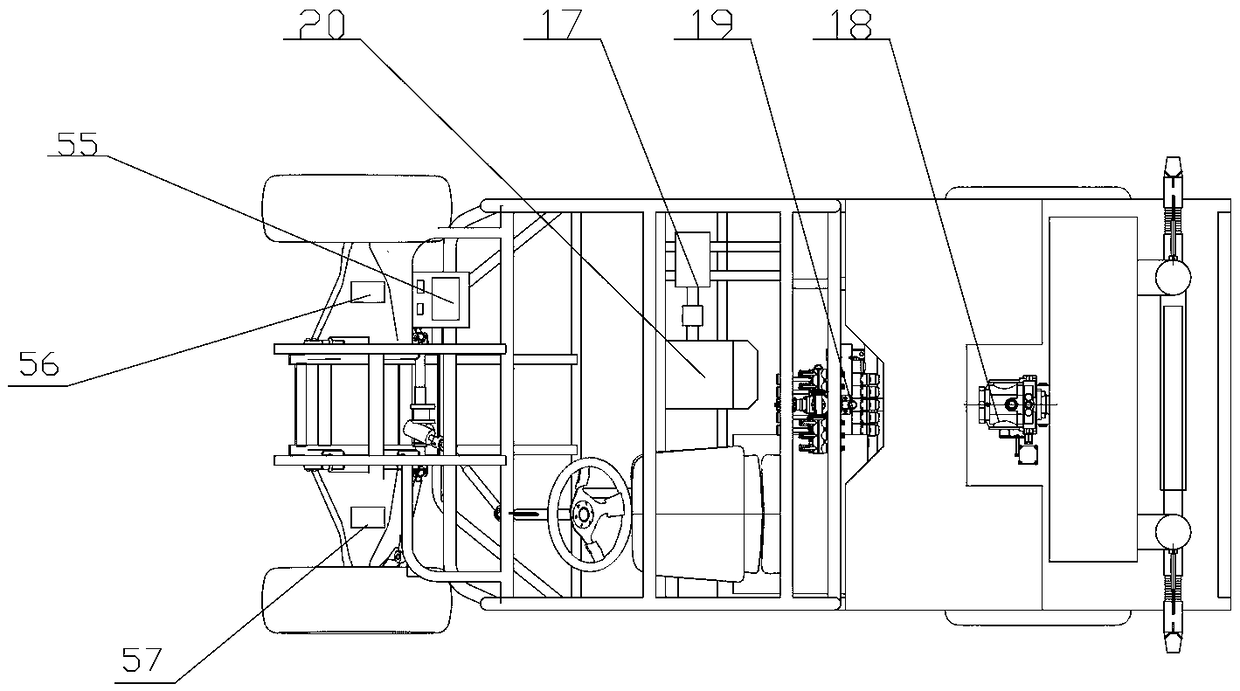

[0035] Such as Figure 1 to Figure 3 The adaptive profiling orchard sprayer shown includes a three-dimensional radar 1, an ARM control unit 55, a car body 2, a medicine box 3, an air collection box 4, a connecting pipe 5, a centrifugal fan 6, a left air blowing spray device 7, a right Air blowing spray device 54, spray motor 17, hydraulic motor integrated pump 18, electromagnetic valve 19 and spray pump 20.

[0036] Both the 3D radar 1 and the ARM control unit 55 are installed at the front end of the car body 2, and the 3D radar 1 includes a left 3D radar 56 and a right 3D radar 57 which are arranged symmetrically. The medicine box 3 is installed in the middle part of the car body 2, the gas collection box 4 is installed on the centrifugal fan 6, and the centrifugal fan 6 is installed on the car body 2, and the left and right sides of the centrifugal fan 6 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com