Rotatable anvil block structure

A technology of anvil and support seat, which is used in manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machines, etc., can solve the problem of inability to rotate large workpieces, etc. Performance, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

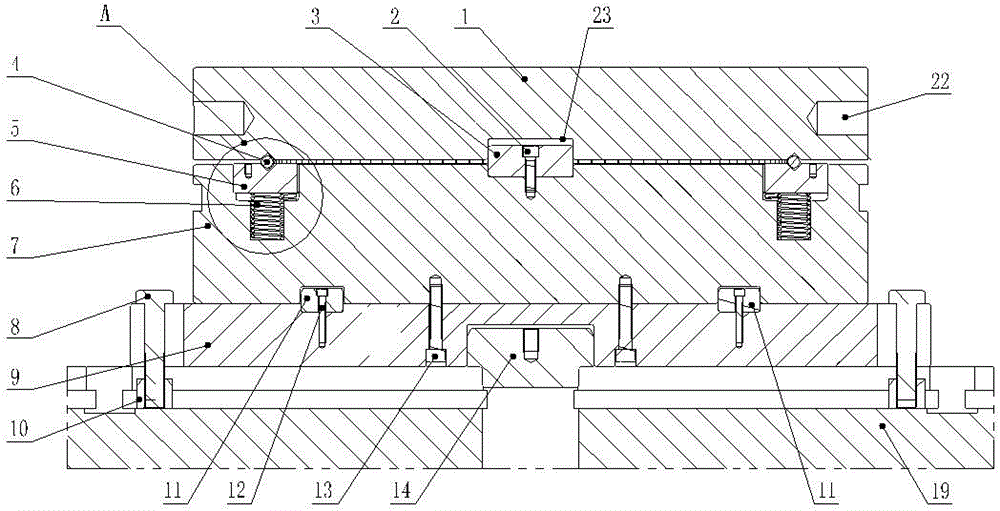

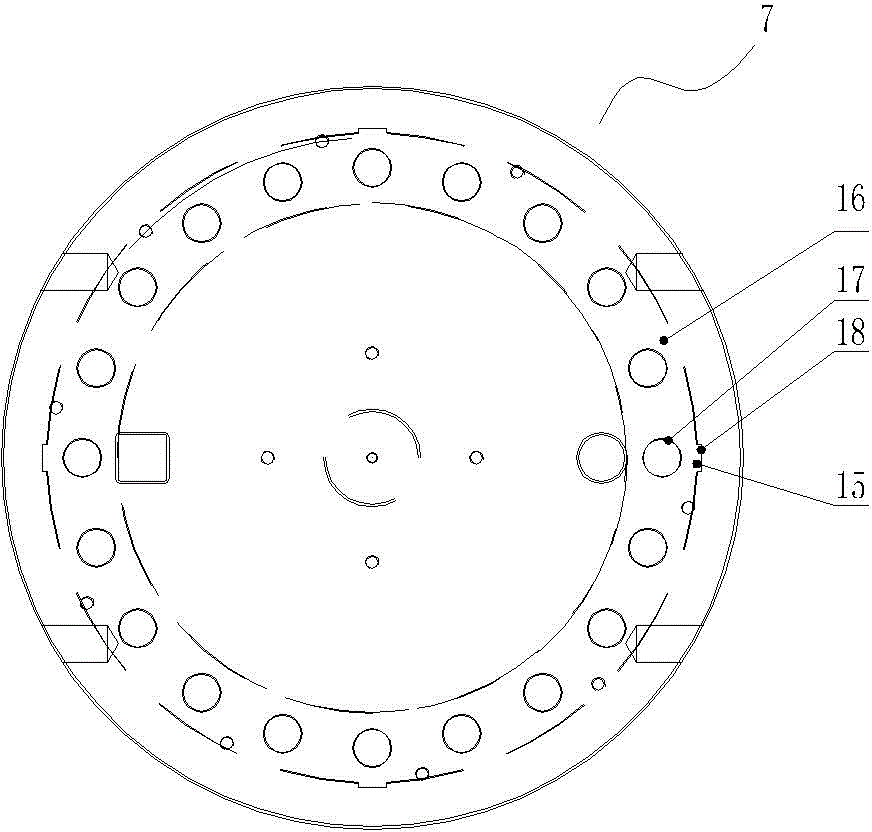

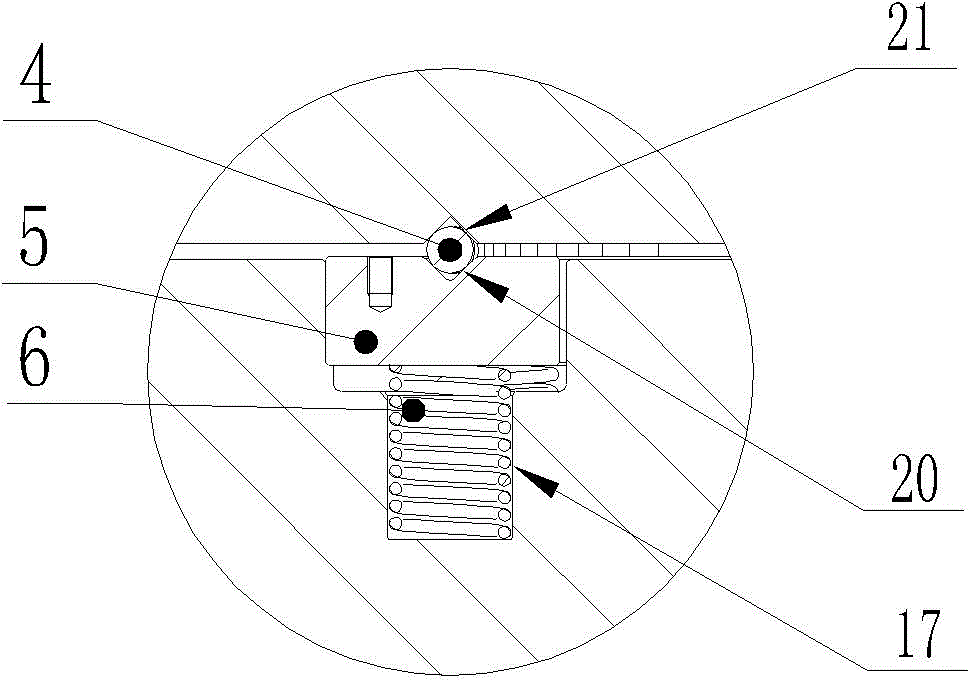

[0017] See figure 1 , figure 2 and image 3 The structure of the present invention includes a base plate 9 and a rotating platform 1. The base plate 9 is installed on the equipment mobile platform 19. A support seat 7 is fixedly installed on the base plate 9. An annular groove 16 is opened on the plane of the support seat 7, and an annular groove 16 is installed in the annular groove 16. Annular slideway 5, the upper plane of annular slideway 5, the lower plane of rotating platform 1 correspondingly have a V-shaped groove 20, 21 respectively, in the V-shaped groove 20 of annular slideway 5, a ring of steel balls 4 is tightly filled, and the rotation The platform 1 is supported by the steel ball 4 in the V-shaped groove 20 of the annular slideway, and the V-shaped groove 21 on the lower plane of the rotating platform 1 is fastened on the steel ball 4, and a horizontal blind hole 22 is opened on the outer peripheral surface of the rotating platform 1 . The center of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com