Convex feeding system of roll grinder

A roll grinder and feed system technology, which is applied to the components of grinding machine tools, grinding drive devices, grinding/polishing equipment, etc., can solve the performance indicators that affect the cutting efficiency and energy consumption of roll grinders, and affect the surface processing of machine tools. Quality grinding accuracy, high productivity and equipment load rate, etc., to meet the needs of strong grinding, easy maintenance and replacement, high productivity and equipment load rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

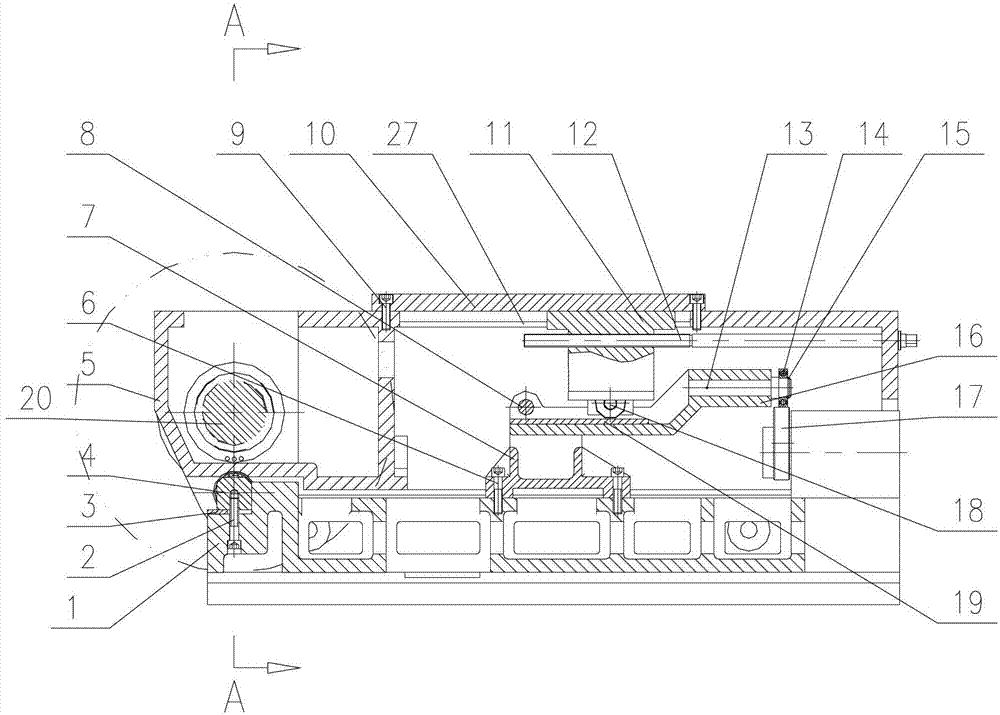

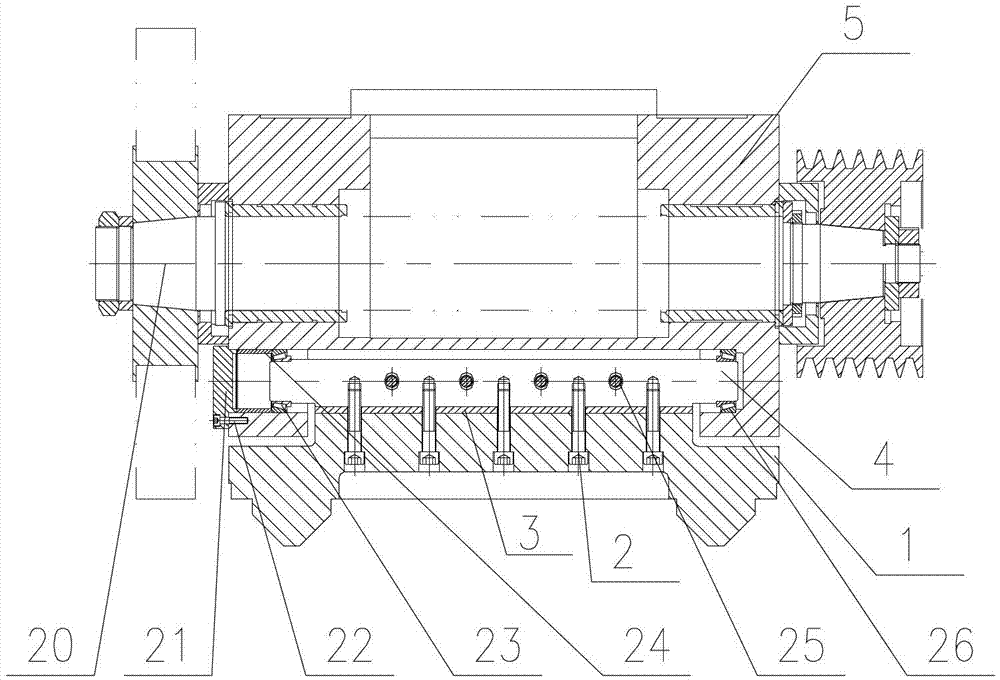

[0015] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0016] Such as figure 1 As shown, the convex feeding system of a roll grinder includes a cross slide 1 and a grinding wheel box 5, and its characteristic is that a supporting shaft 4 is arranged between the grinding wheel box 5 and the cross slide 1, The support shaft 4 is fixedly connected with the slide seat 1, and the two ends of the support shaft 4 are installed on the lower part of the grinding wheel box 5 through the first tapered roller bearing 23 and the second tapered roller bearing 26 respectively, and the front end of the grinding wheel box 5 is provided with a spindle assembly 20. The eccentric cam box 17 is set on the slide seat 1, one end of the swing frame 16 is in contact with the eccentric cam box 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com