Cranes and their fuel tanks

A technology of fuel tanks and tanks, which is applied to the layout combined with the fuel supply of internal combustion engines, power devices, vehicle components, etc., which can solve the problems of insufficient fuel intake, engine flameout, etc., and achieve the effect of simple and reliable structure and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be noted that the embodiments of the present invention and the features in the embodiments can be combined with each other if there is no conflict. Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

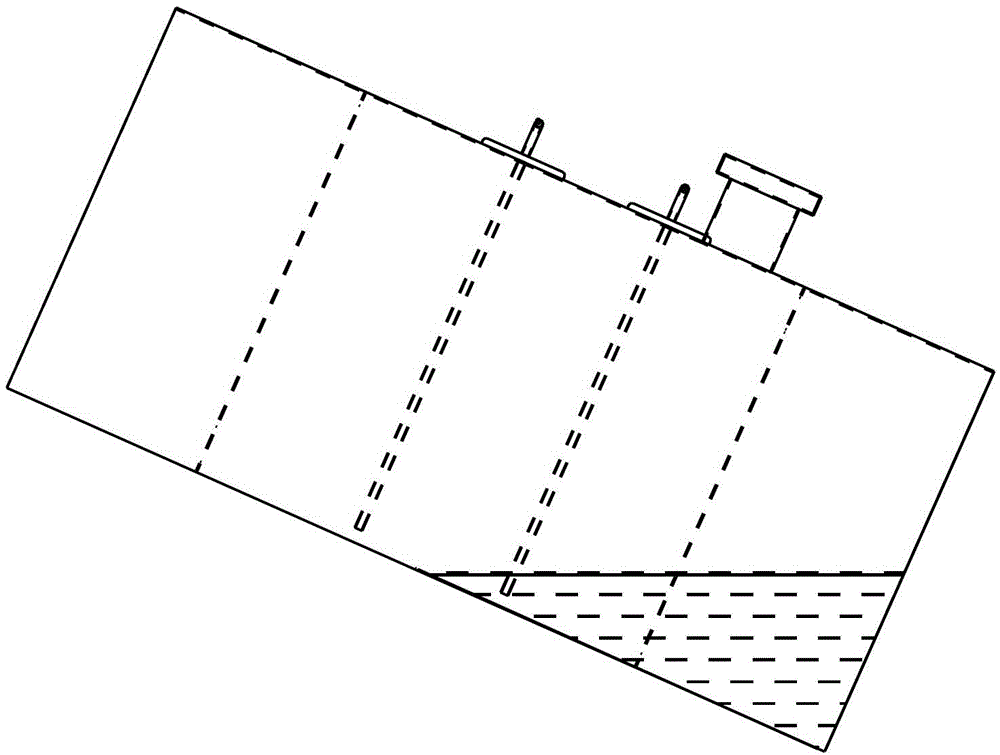

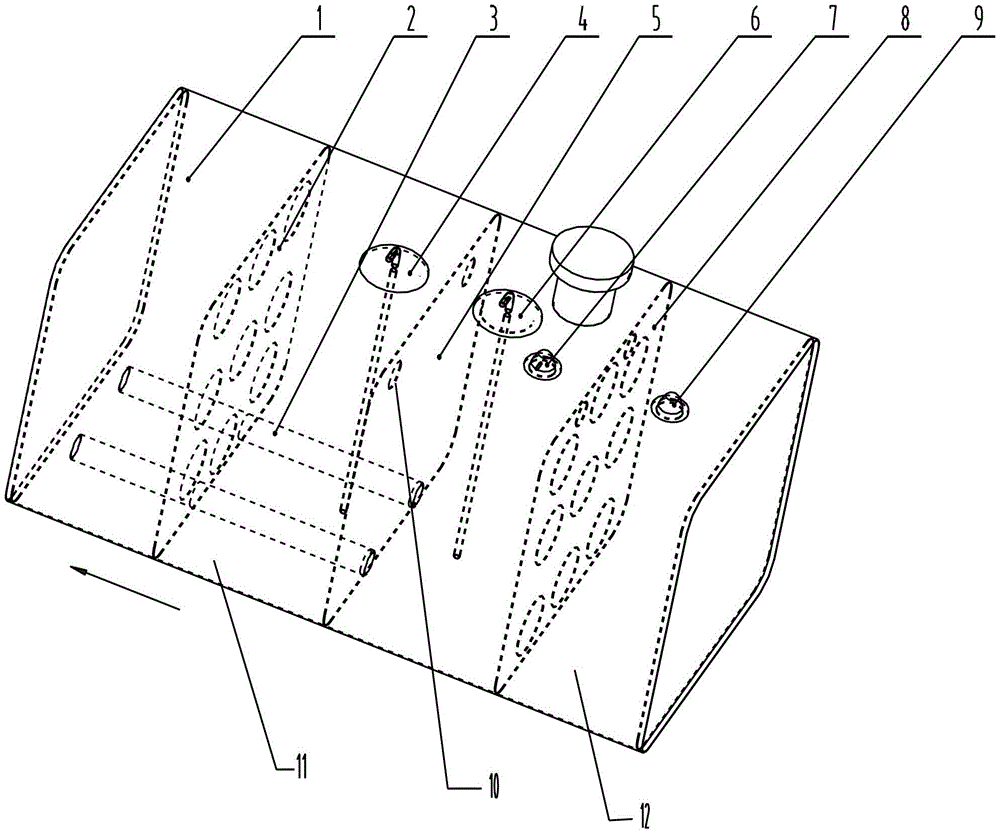

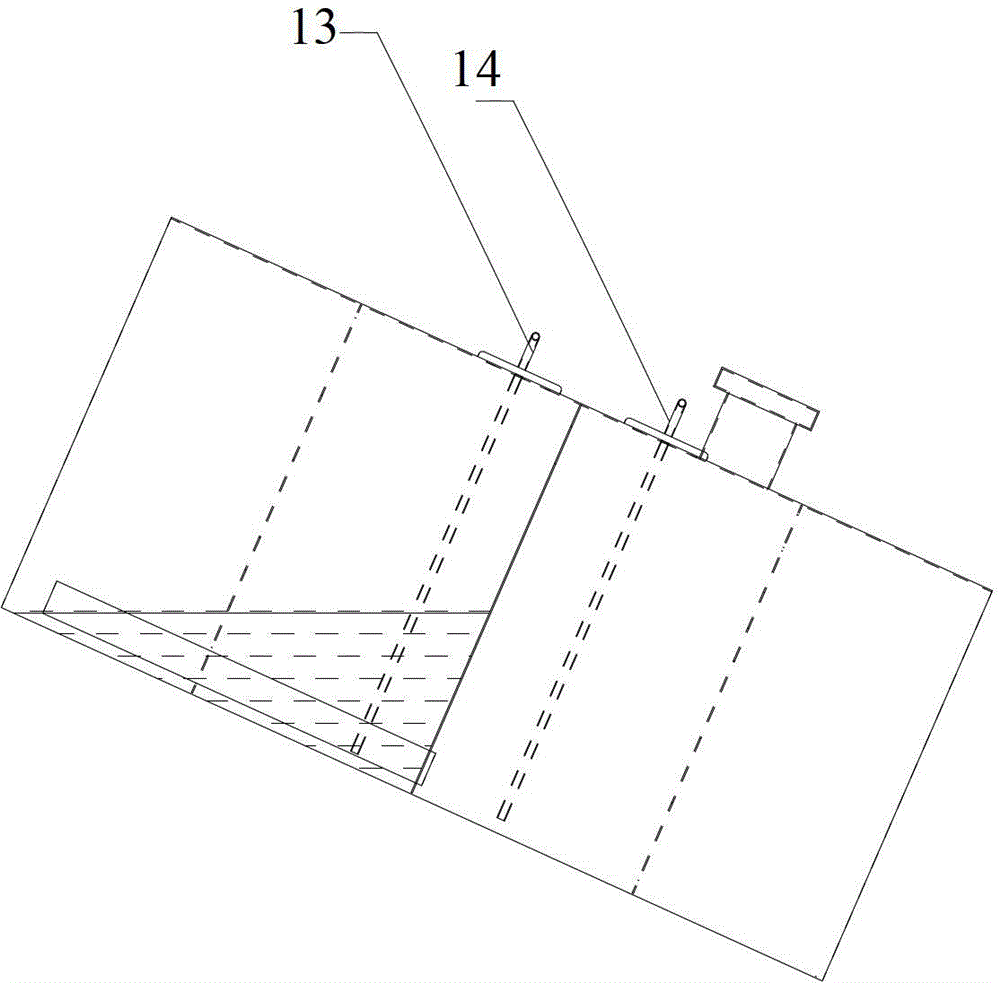

[0035] Combine below Figure 2 to Figure 3 , The preferred embodiment of the present invention will be further described in detail.

[0036] The fuel tank of this embodiment is used in a crane and includes a tank body 1 and an oil suction assembly and an oil return assembly provided on the tank body 1. In addition, the fuel tank also includes a partition 5 and an oil pipe assembly. The partition 5 is arranged in the box 1 to divide the box 1 into a first cavity 11 and a second cavity 12 along the length direction. The top of the partition 5 is also provided with a balance hole 10 for balancing the air pressure of each cavity. The oil pipe assembly includes at least one oil pipe 3, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com