A burner with arc-shaped body jet device

A jet device and shape technology, applied in the field of new burners, can solve the problems of insufficient combustion of fuel gas, low combustion temperature, easy flame failure and other problems, and achieve the effects of ensuring impact force, accelerating chemical reaction and reducing kinetic energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

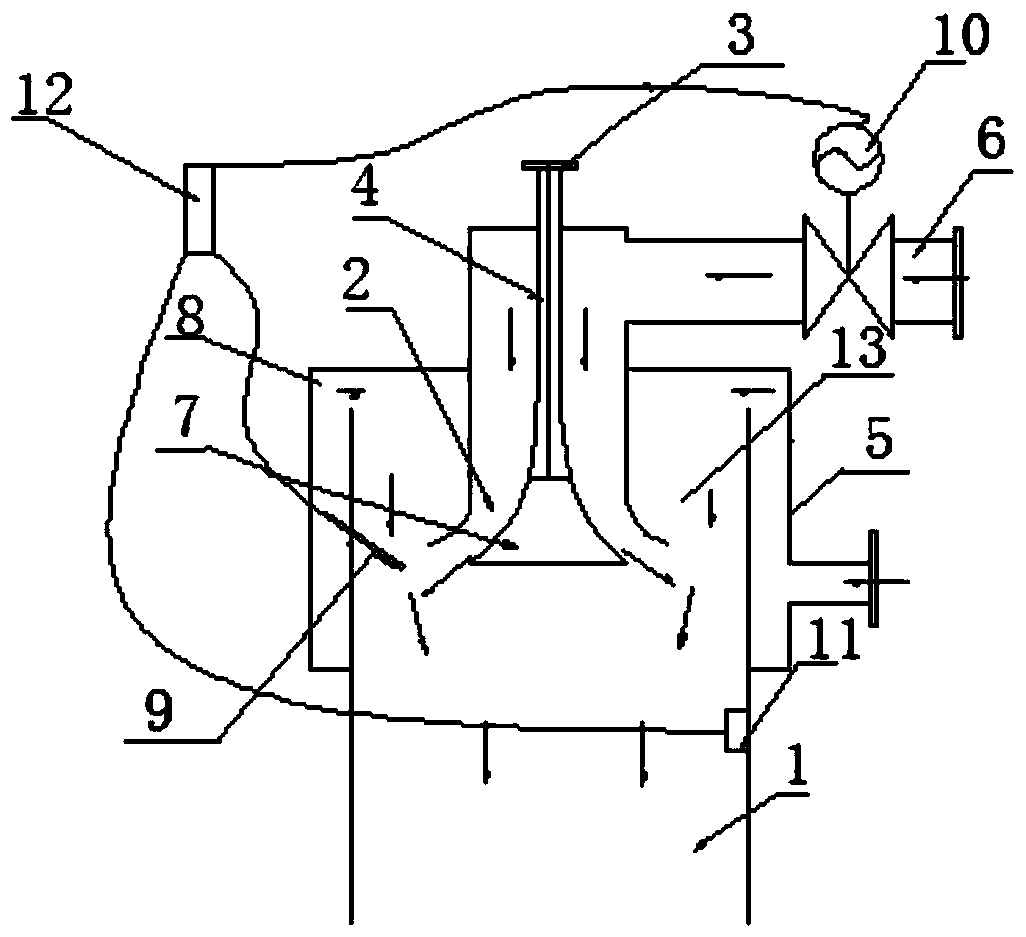

[0027] figure 1 Shown is an embodiment of the novel burner with arc-shaped body jet device of the present invention, the novel burner with arc-shaped body jet device includes combustion tube 1, nozzle 2, arc-shaped body jet device, air Pipe 5, gas pipe 6, automatic ignition device 9 and controller 12.

[0028] The nozzle 2 is a streamlined cavity structure with an inlet and an outlet, the inlet of the nozzle 2 is fixedly connected to the gas pipe 6, and the outlet of the nozzle 2 extends into the rear end of the combustion pipe 1, so The front end of the combustion tube 1 is a flame outlet; the outlet of the nozzle 2 is an involute opening structure. The nozzle 2 is streamlined, and the method of using the jet to induce air can reduce the loss of kinetic energy, prevent the backflow of gas, realize automatic air distribution, and make full use of the gas; due to the adoption of the air induction method, the combustion-supporting fan is removed, which saves Power consumption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com