burner

A burner and gas technology, which is applied in the field of kitchen gas stoves, can solve the problems of user maintenance, inconvenient cleaning, cumbersome installation, and influence on burner ejection, etc., to solve the problem of flameout when opening and closing cabinet doors, the overall structure is compact and reasonable, and prevent overflow The effect of liquid clogging the nozzle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

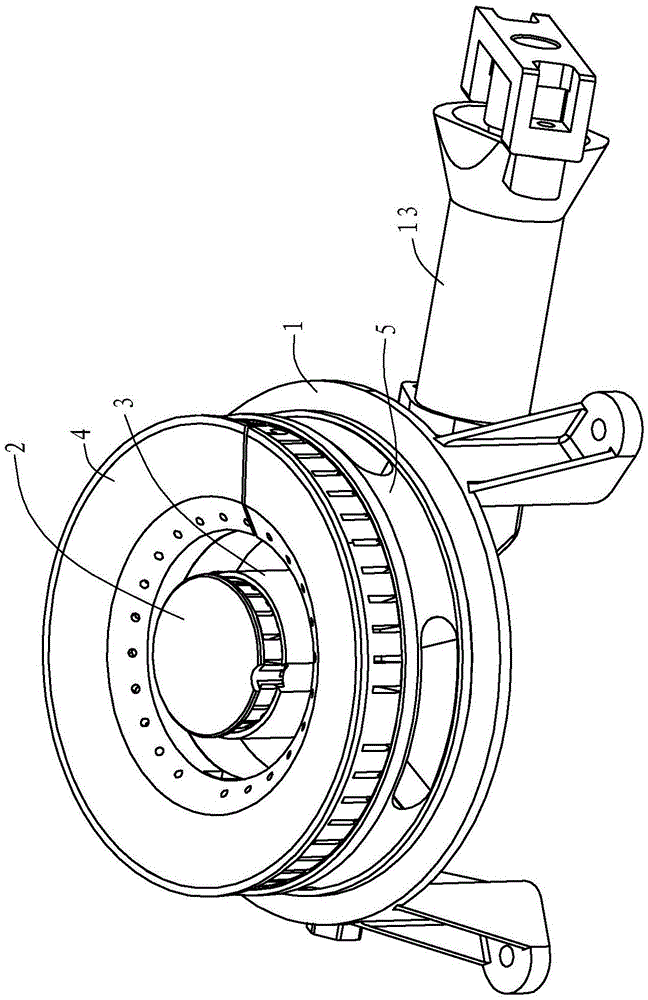

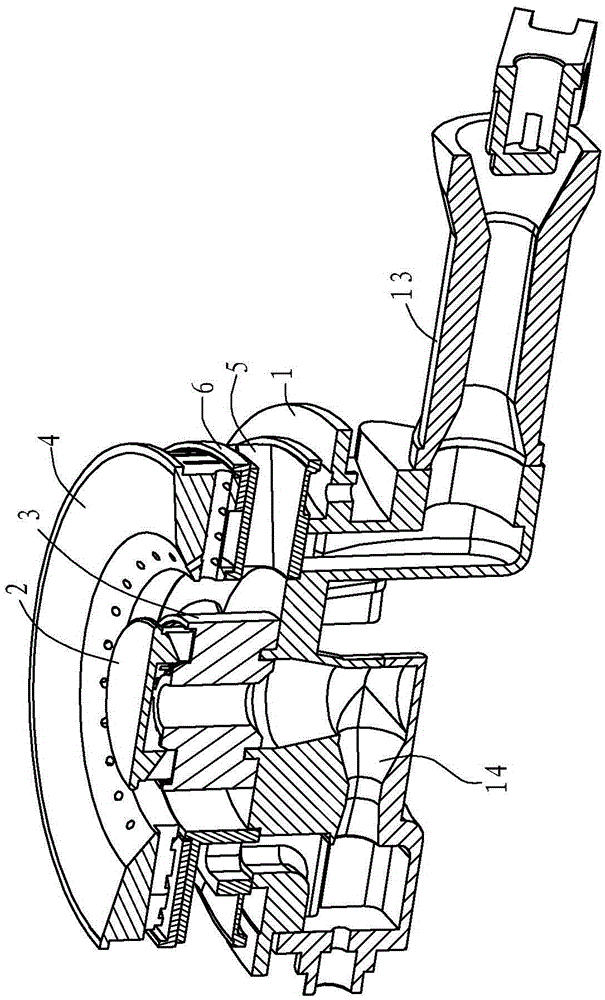

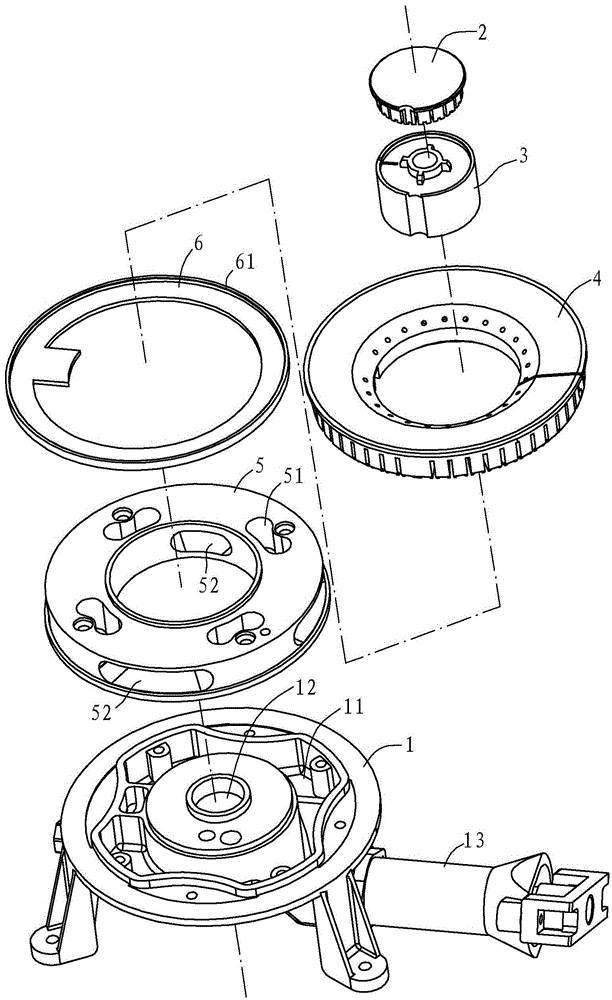

[0019] Such as figure 1 , figure 2 with image 3 As shown, the burner in this embodiment includes a base 1, an outer gas seat 5, an inner gas seat 3, a backing ring 6, an outer fire cover 4 and an inner fire cover 2, and the base 1 is provided with an external output with openings all upward. The port 11 and the inner output port 12, the base 1 is connected with an injection tube for gas to enter, and the injection tube includes an outer injection tube 13 communicated with the outer output port 11 and an inner injection tube 14 communicated with the inner output port 12 , And, the outer injection pipe 13 has an introduction channel for air to enter.

[0020] The outer gas seat 5 is annular, and the outer gas seat 5 is arranged on the base 1 and covers the outer output port 11, the inner gas seat 3 is arranged on the inner output port 12 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com