Ignition control method for spray granulation tower burner and ignition control device

A spray granulation tower and ignition control technology, which is applied in the direction of controlling combustion, lighting and heating equipment, etc., can solve the problems of burner flameout and equipment flameout, and achieve the effects of reducing workload, stable equipment operation, and easy fault analysis and handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

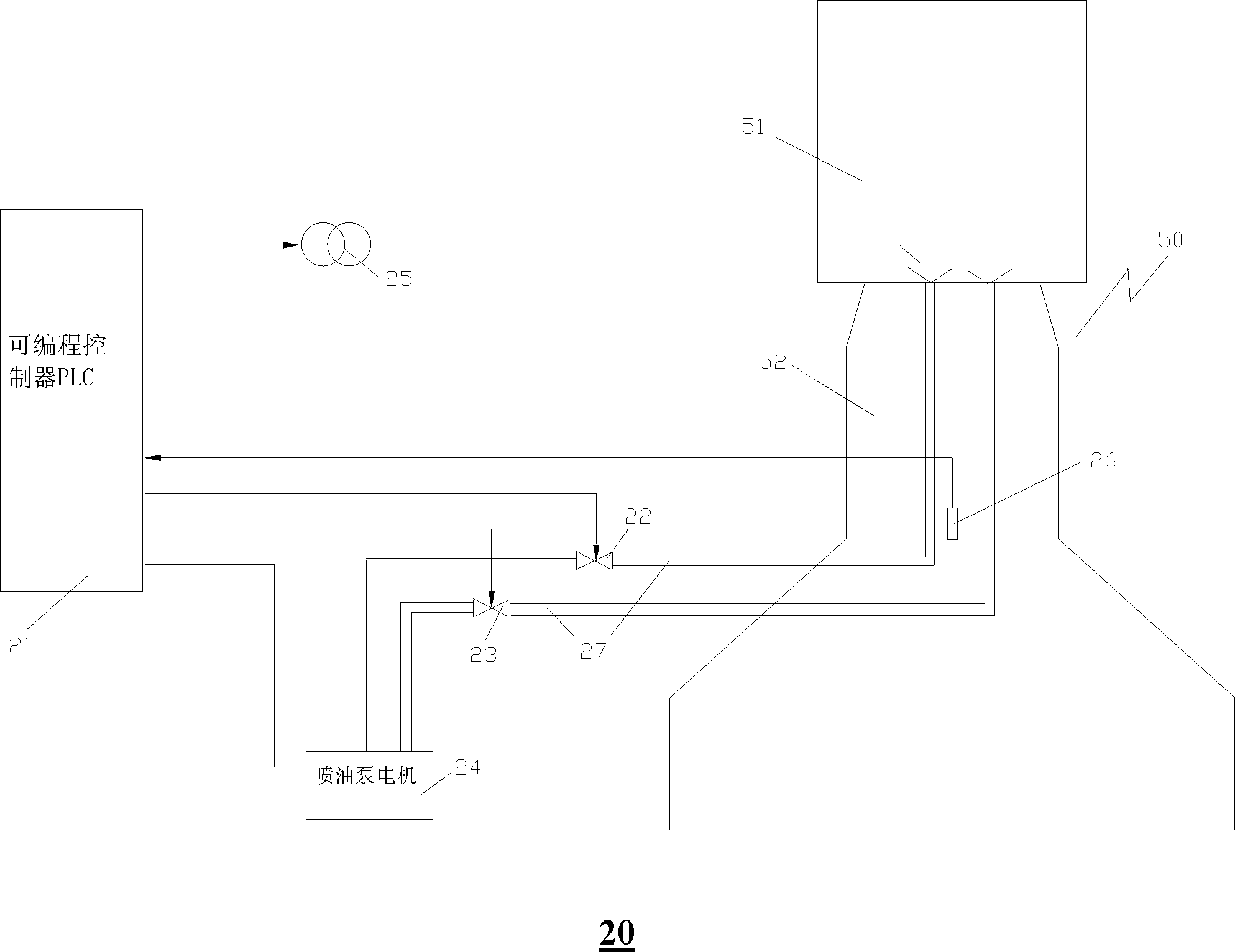

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

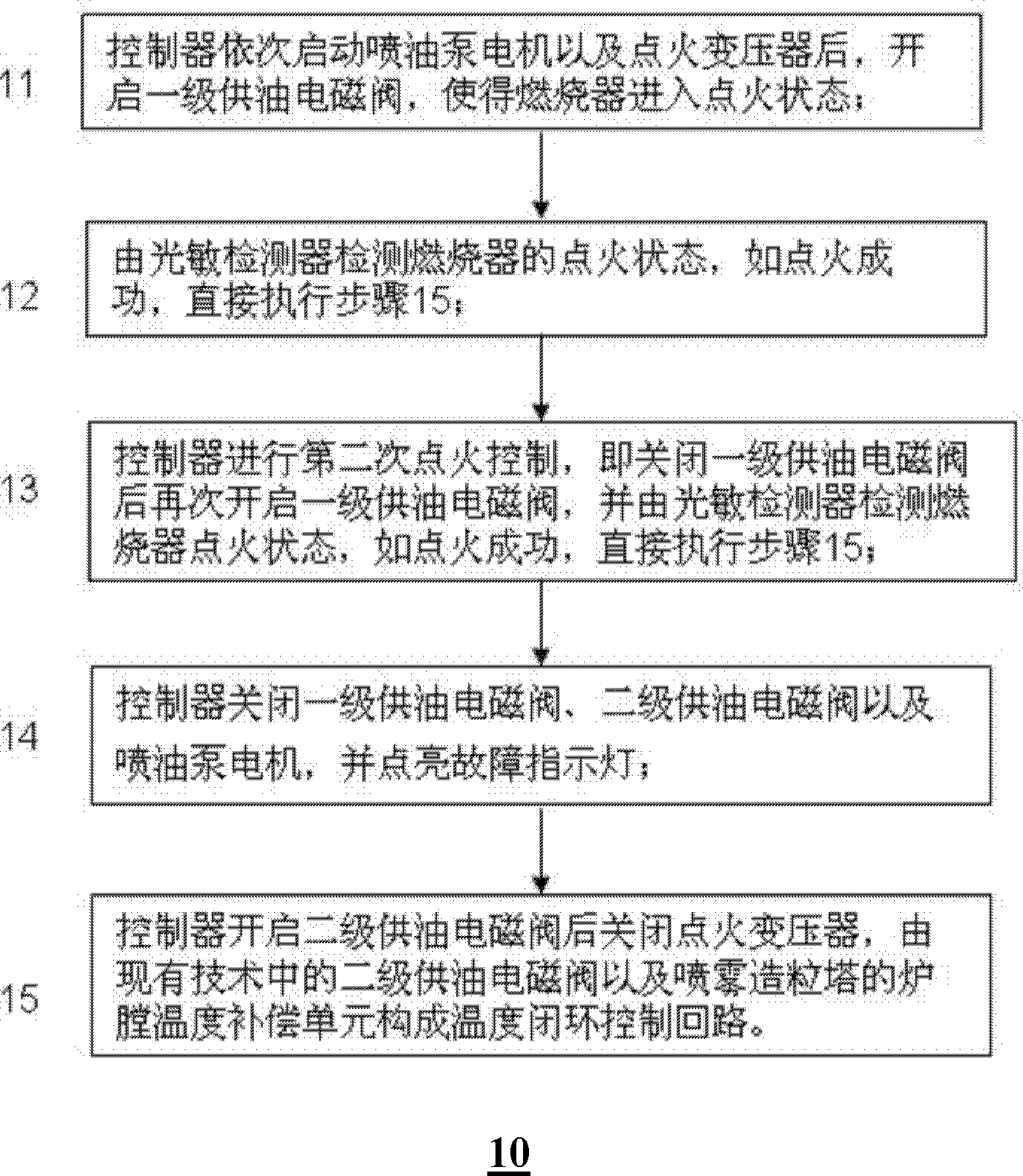

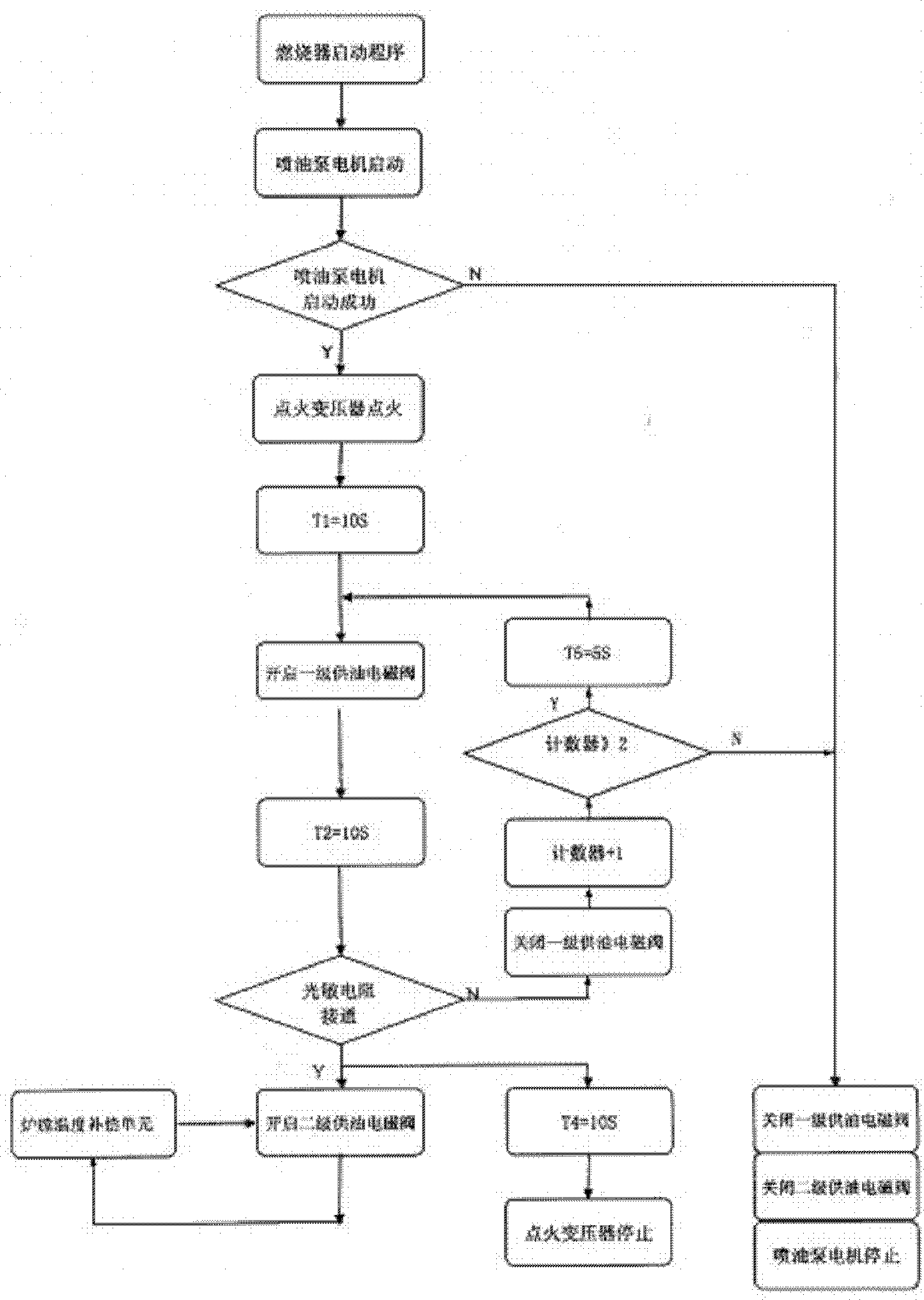

[0027] see figure 1 Shown is an ignition control method 10 for a spray granulation tower burner, the specific steps of the ignition control method are:

[0028] 11. After the controller starts the fuel injection pump motor and the ignition transformer in sequence, it opens the primary oil supply solenoid valve to make the burner enter the ignition state;

[0029] 12. Detect the ignition state of the burner by the photosensitive detector, if the ignition is successful, directly perform step 15;

[0030] 13. The controller performs the second ignition control, that is, closes the primary fuel supply solenoid valve and then opens the primary fuel supply solenoid valve again, and detects the ignition status of the burner by the photosensitive detector. If the ignition is successful, directly execute step 15;

[0031] 14. The con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com