Pneumatic correction device for cell transferring

A calibration device and cell technology, which is applied in the field of solar cells, can solve the problems of reduced precision, generation of debris, and easy deviation of cells, so as to prevent deviation and debris, realize position correction, and ensure synchronous action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

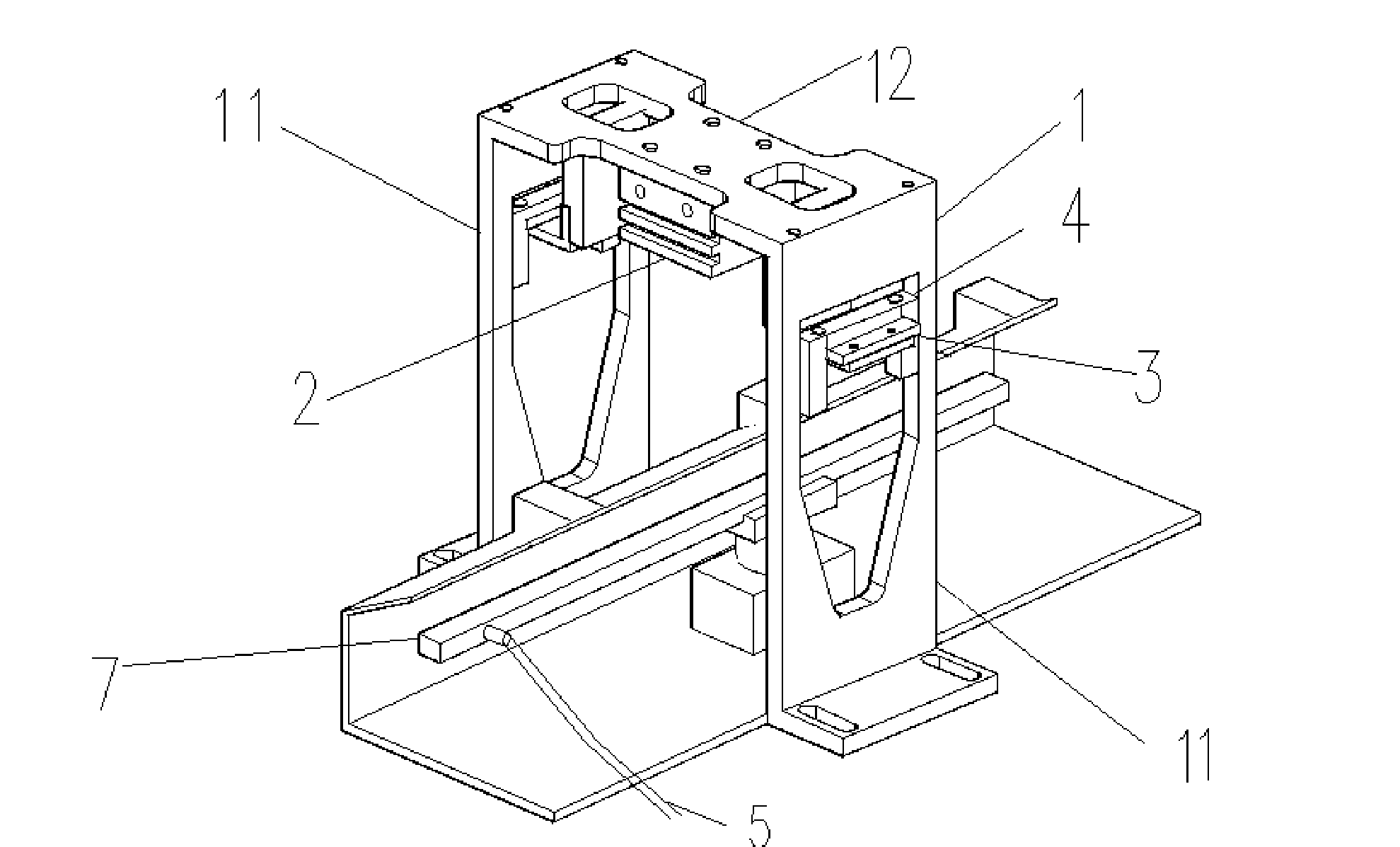

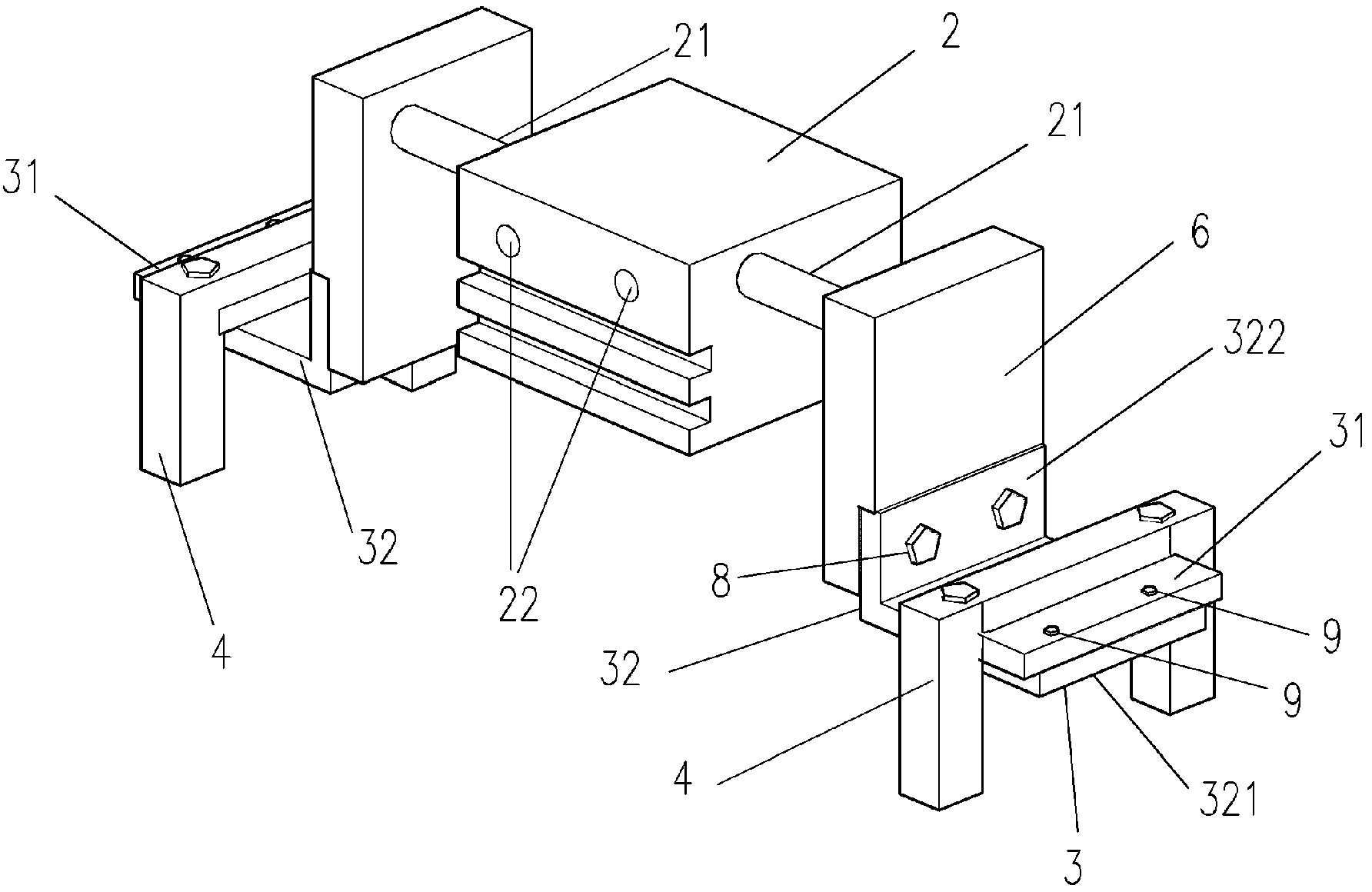

[0018] Such as Figure 1-2 As shown, a pneumatic correction device for cell transmission includes a base 1, a cylinder 2, a combined baffle 3, a U-shaped clamp arm 4, a proximity switch 5 and a sensing element. A pair of side plates 11 on the side and a top plate 12 located on the top of the pair of side plates, the cylinder 2 is arranged below the top plate 12, and the combined baffle plate 3 is a pair, which are symmetrically installed on the guide rods 21 on both sides of the cylinder 2 and located Below the cylinder 2, a pair of U-shaped clamp arms 4 are symmetrically installed on the combined baffle plate 3 respectively. The guide rod 21 shrinks or stretches to drive the movement of the U-shaped clamp arm 4 to correct the position of the battery sheet.

[0019] In order to realize that the pneumatic device can calibrate cells of different sizes on the conveying arm, the combined baffle 3 is composed of an upper baffle 31 and a lower baffle 32, wherein the upper baffle 31...

Embodiment 2

[0028] The difference from Embodiment 1 is that the detachable connection modes of the upper baffle 31 and the flat part 322 of the lower baffle 32 in the combination baffle 3 in this embodiment are different, and the flat part 321 of the lower baffle 32 in this embodiment There are two rows of parallel screw holes, and the upper baffle plate 31 is provided with fixing bolts 9 at positions corresponding to the screw holes. By adjusting the position of the fixing bolt 9 on the upper baffle plate 31 in the first row or the second row of screw holes of the lower baffle plate, the upper baffle plate 31 is positioned at different positions of the lower baffle plate plate portion 322 to realize the U-shaped clamp arm. position adjustment. This is only the preferred detachable mode of the present invention, and other detachable connection modes can be adopted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com