Hot air duct for dry oven of tentering and setting machine

A stenter setting machine and hot air duct technology, applied in the direction of fabric elongation, textile and paper making, fabric surface trimming, etc., to achieve uniform hot air, energy saving, and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

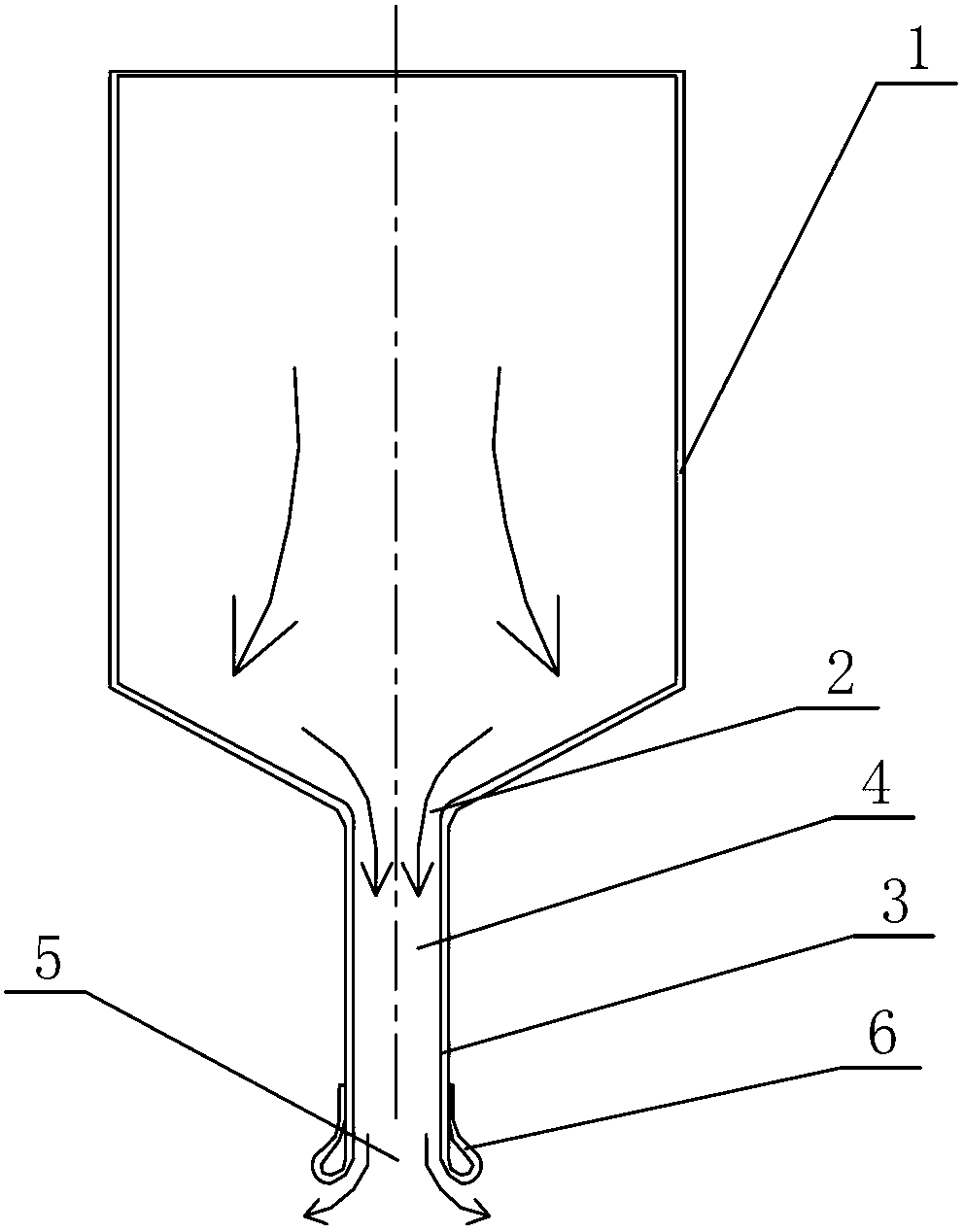

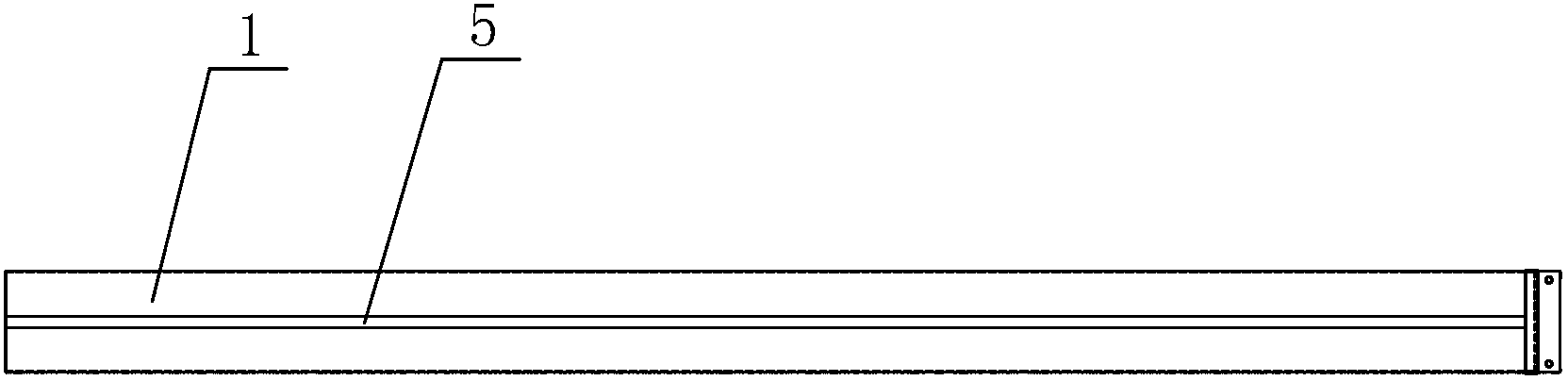

[0016] see figure 1 and figure 2 as shown, figure 1 It is a cross-sectional view of the hot air duct used in the oven of the tenter setting machine provided by Embodiment 1 of the present invention; figure 2 yes figure 1 bottom view.

[0017] In this embodiment, a hot air duct for a stenter setting machine oven includes an air duct body 1, the air duct body 1 is made of galvanized sheet, and its cross-section is a rectangular structure, and the air duct body 1 1 is provided with an air outlet 2 that runs through the entire air duct body 1, and the air outlet 2 extends outwards with a nozzle 3, and the nozzle 3 includes an air uniform channel 4 that is sealed and connected with the air duct body 1, and the air uniform channel The end of 4 is a nozzle opening 5, and the two sides of the end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com