A method for controlling lubrication of a gear unit and a gear unit

A gear unit, controller technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, thin material handling, etc., to achieve the effect of improving the flow of lubricating fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

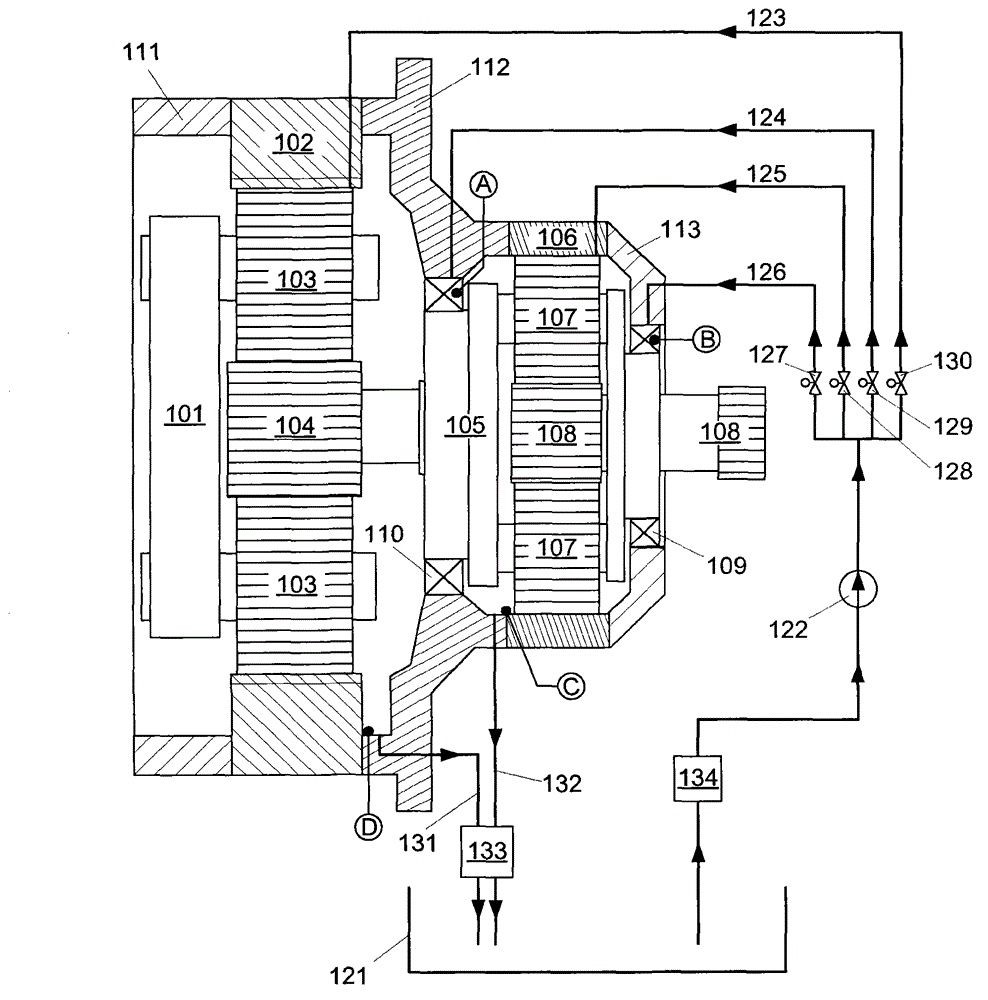

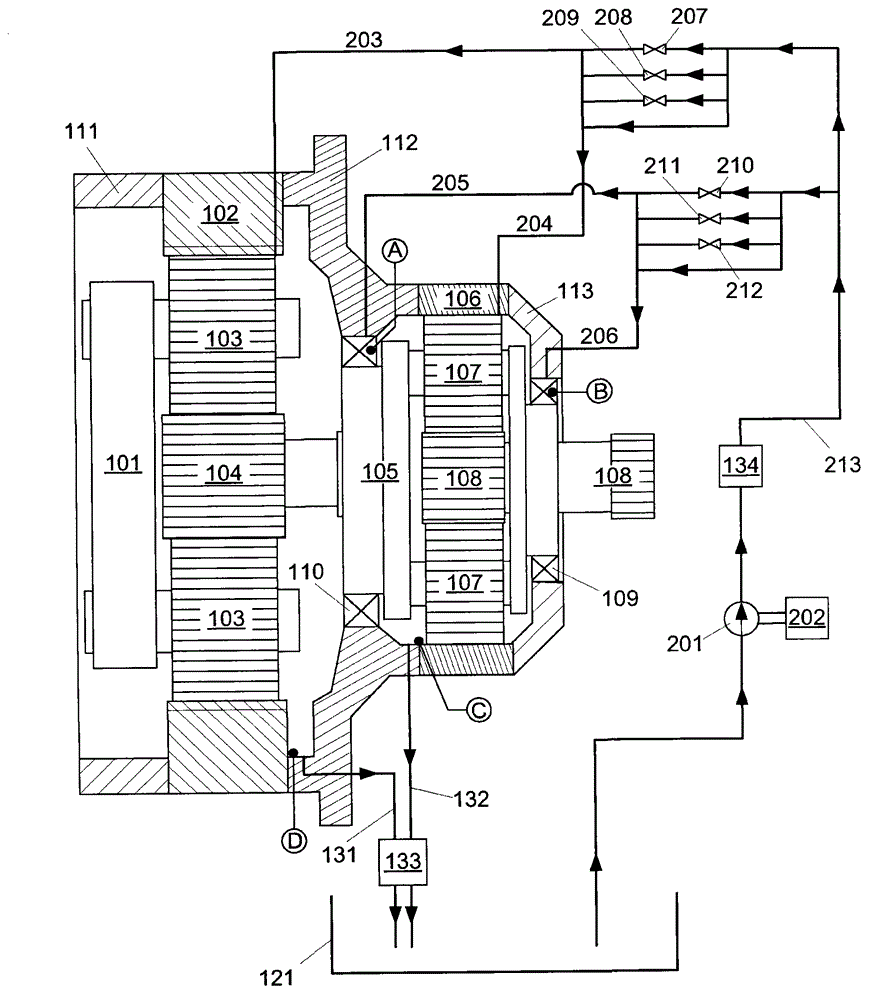

[0024] figure 1 A schematic sectional view of a gear unit according to an advantageous exemplary embodiment of the invention is shown.

[0025] figure 1 The gear unit disclosed in is a planetary gear unit comprising two planetary gear stages. The first planetary gear stage comprises a planet carrier 101 , a ring gear 102 , planet wheels 103 and a sun gear shaft 104 . The second planetary gear stage includes a planet carrier 105 , a ring gear 106 , planet wheels 107 and a sun gear shaft 108 . The planet carrier 101 of the first planetary gear stage forms part of a mechanical interface structure arranged to receive mechanical power from a suitable prime mover. Thus, the planet carrier 101 of the first planetary gear stage is rotated by the prime mover. Ring gear 102 is stationary. The sun gear shaft 104 of the first planetary gear stage is connected to the planet carrier 105 of the second planetary gear stage. Thus, the planet carrier 105 of the second planetary gear stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com