Method for measuring inner arc ultrasonic sound energy loss of small diameter tube

A technology for ultrasonic and small-diameter tubes, which is applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids and other directions, and can solve problems such as missed welds and arc scattering in small-diameter tubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

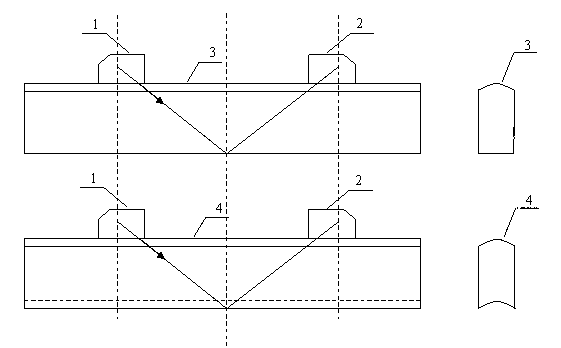

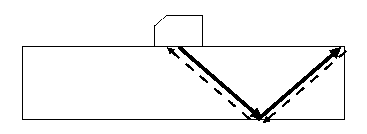

[0026] Depend on figure 1 As shown, the embodiment steps are as follows:

[0027] 1) Preparation of probe and ultrasonic inner arc sound energy loss measurement test block group:

[0028] Probe selection: Select a small-diameter tube ultrasonic transmitting probe 1 and a small-diameter tube ultrasonic receiving probe 2 with specifications of 5P6×6K2.5, leading edge of 5mm, and delay of 2.60μs. The probes are connected to the CTS- 9002 digital ultrasound machine;

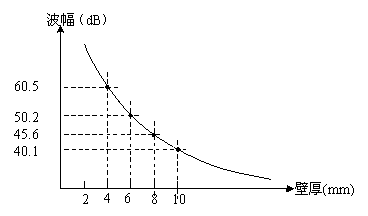

[0029] Select the ultrasonic inner arc sound energy loss measurement test block: when the inspected workpiece 4 is a small-diameter tube of 20g and Φ57×8mm, select a group of ultrasonic inner arc sound energy loss measurement test blocks 3 made of the same material as the inspected workpiece 4 , one group includes four test blocks 3 with a length of 100 mm, a width of 15 mm, and different thicknesses. The thicknesses of the four test blocks are respectively 4 mm, 6 mm, 8 mm, and 10 mm; the ultrasonic inner arc soun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com