Module connector

A technology of connectors and functional modules, applied in the direction of connection, parts of connection devices, contact parts, etc., can solve the problems of scrapped printed boards and other problems, and achieve the effect of avoiding overall scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

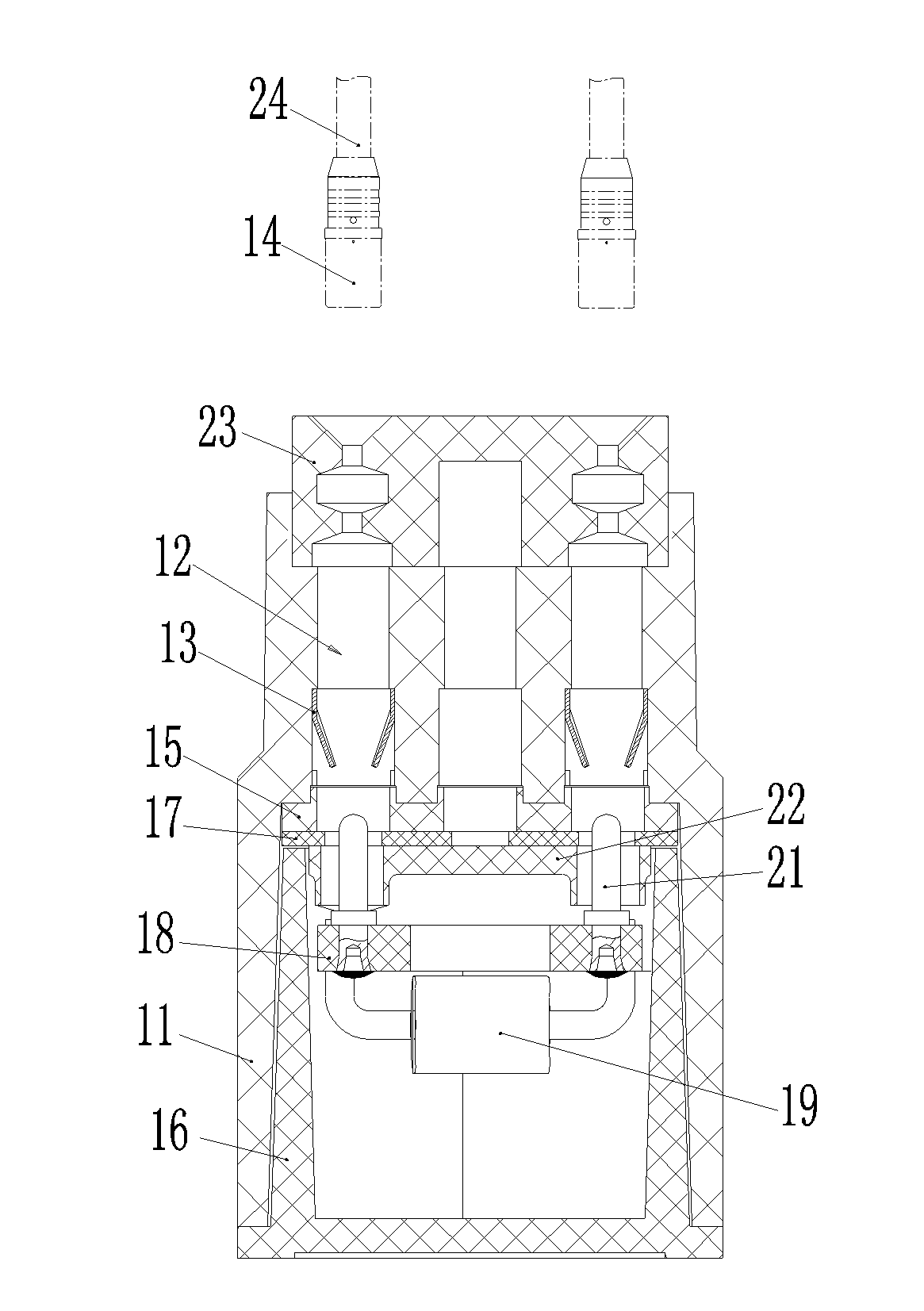

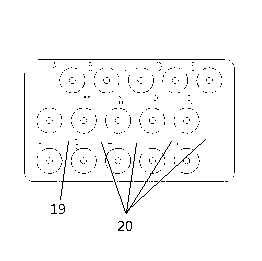

[0017] Embodiment 1 of the modular connector of the present invention, such as Figure 1-2 As shown, the connector uses the front end as the plug-in end, and it includes a housing 11. In this embodiment, the housing 11 is made of insulating material. Viewed from the outside, it is in the shape of a stepped shaft, including a small diameter section at the front end and a The large-diameter section located at the rear, viewed from the inside, has a rear-facing stepped surface on the inner wall surface of the housing 11 at the junction of the large-diameter section and the small-diameter section, and the small-diameter section is provided with a plug for the adapter contact to insert. Connection hole 12; the hole wall of the insertion hole 12 also has a step surface facing the rear, and the rear part of the step surface on the hole wall in the insertion hole 12 is equipped with a fixed coil 13, and the fixed coil 13 has The barbed structure used to prevent the fitting contact 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com