Casting method of solid stainless steel cooler

A stainless steel, solid technology used in the foundry field to solve the problems of scrapped finished products, blocked pipes, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

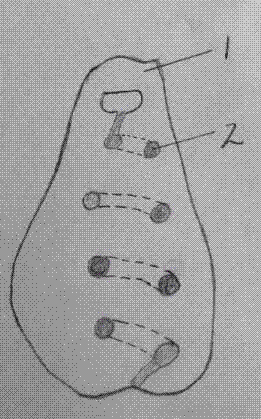

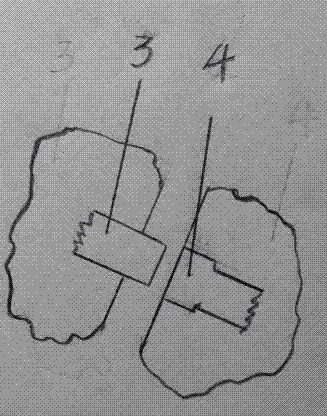

[0008] exist figure 1 In the process, the stainless steel hollow shell (1) or the solid shell (1) of the left and right halves are respectively casted with molds. If the casting is half of the solid shell (1), because the pipe (2) of the half solid shell (1) is a separate cavity, it can be cast in the traditional way, and then the left and right two stainless steel half The solid housing (1) is assembled and welded together. When casting half a solid shell (1), cast the left and right shells separately, the position of the pipe on the left shell is slightly higher, and the pipe on the splicing surface protrudes (3) by a small section. The position of the pipe on the right shell is slightly lower, and the pipe on the splicing surface is recessed (4) for a small section. When the left and right two half-side solid shells are assembled and welded, the concave and convex are just connected and then welded. Finally, the welded semi-finished product is ground and polished to beco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com