An u-iron frame type straightening drum

A channel steel frame and straightening technology, applied in the field of straightening cylinders, can solve the problems of difficult processing, difficult to discharge dust of the straightening cylinder, troublesome operation, etc., and achieve the effects of long service life, good dust discharge performance and simple main structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

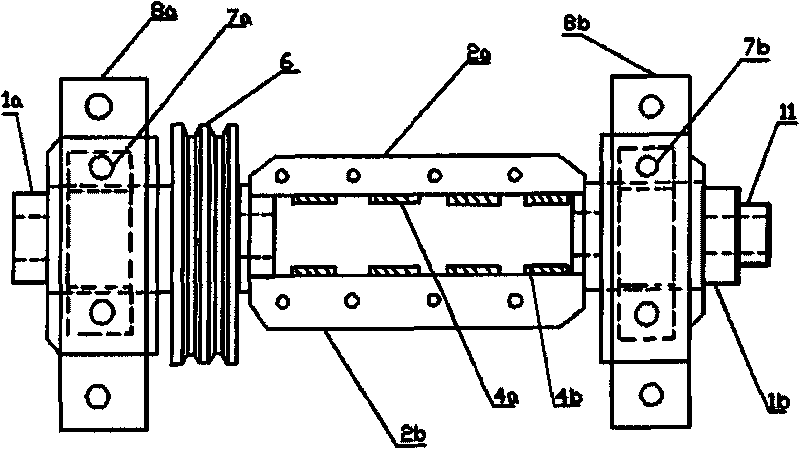

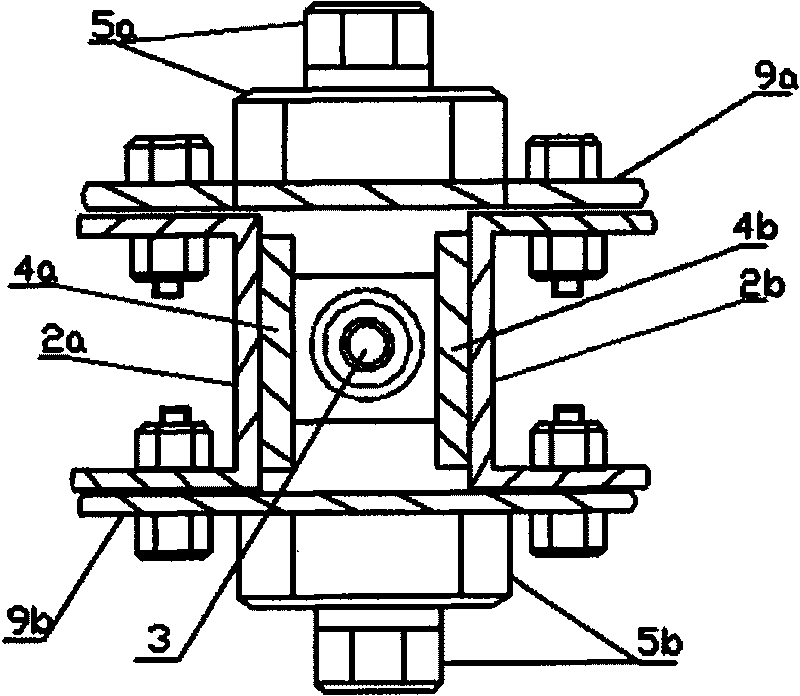

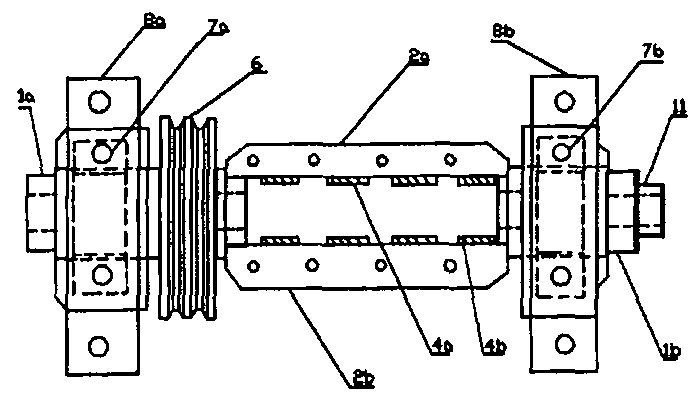

[0026] A channel steel frame type straightening cylinder, comprising a front hollow mandrel 1a, a rear hollow mandrel 1b, an upper fixed channel steel 2a, a lower fixed channel steel 2b, an upper straightening block intermediate positioning plate 4a, a lower straightening block intermediate positioning plate 4b, Up-adjust the straight block pressure screw adjustment nut 5a, down-adjust the straight block pressure screw adjustment nut 5b, up-adjust the straight block movable pressure screw plate 9a, and down-adjust the straight block movable pressure screw plate 9b, wherein: one end of the front hollow mandrel 1a is connected with the upper One end of the fixed channel steel 2a is fixedly connected with one end of the lower fixed channel steel 2b. The upper fixed channel steel 2a and the lower fixed channel steel 2b are symmetrically distributed. The middle positioning plate 4b of the block is fixed on the inner surface of the lower fixed channel steel 2b, and the other ends of ...

Embodiment 2

[0029] A channel steel frame type straightening cylinder, wherein: the front bearing 7a is installed in the front bearing seat 8a, and the front bearing 7a is set on the front hollow mandrel 1a; the rear bearing 7b is installed in the rear bearing seat 8b, and the rear bearing 7b is set on the On the rear hollow mandrel 1b; the belt pulley 6 is also sleeved on the front hollow mandrel 1a, and the rear feed alloy sleeve hole 11 is docked with the rear hollow mandrel 1b. All the other are with embodiment 1.

[0030] The working principle is described in conjunction with the embodiment: in fact, the front bearing 7a, the rear bearing 7b, the front bearing seat 8a, the rear bearing seat 8b, and the belt pulley 6 all belong to the drive components. Other forms of driving components can also be used to drive the channel steel frame type straightening cylinder to rotate.

[0031] The rear feed alloy sleeve hole 11 is used to guide the steel bar head into the channel steel frame type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com