A squirrel cage rigid jumper

A rigid jumper and squirrel-cage technology, applied in the field of rigid jumpers, can solve the problems of difficult wire layout and inability to meet the vibration requirements of the sub-gap, and achieve the effects of simple structure, convenient installation and disassembly, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

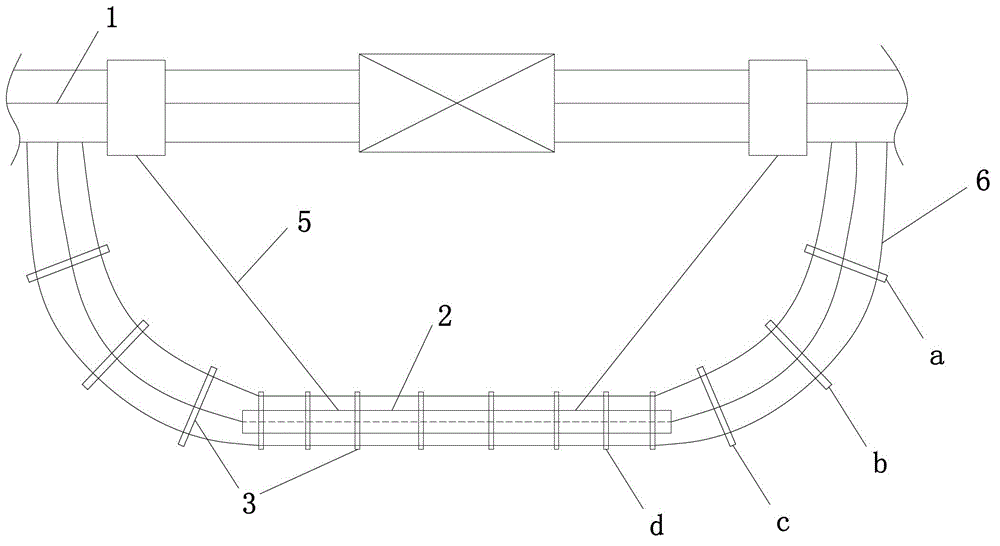

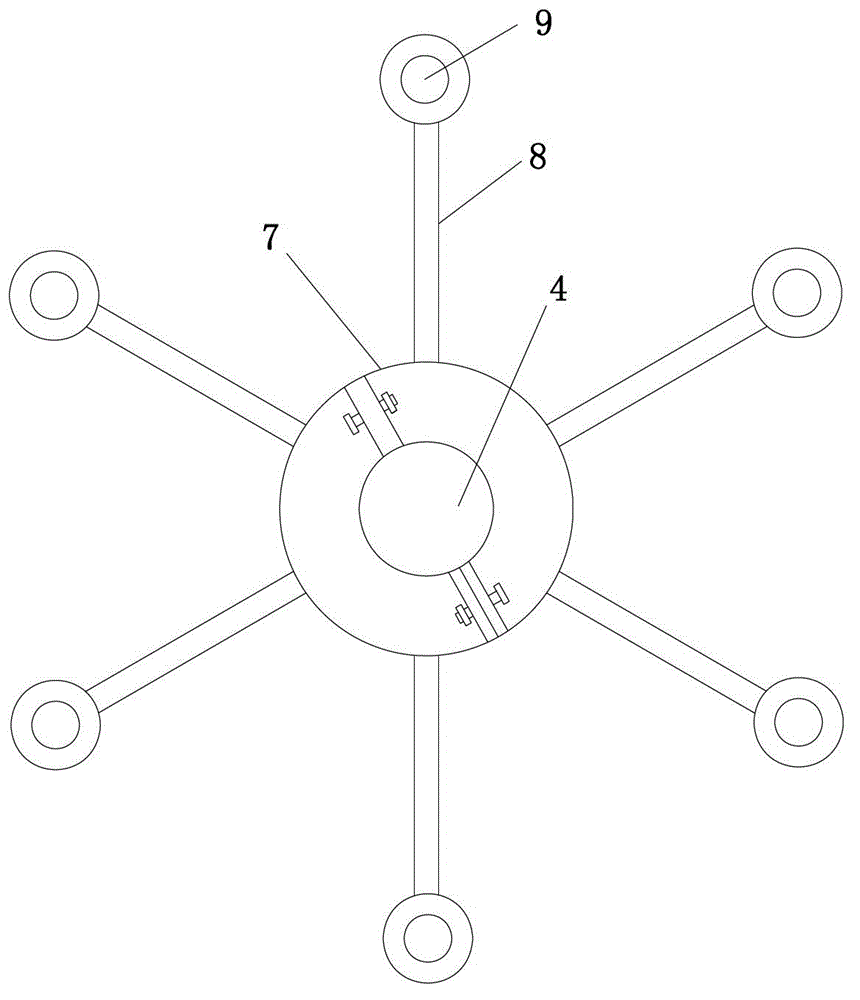

[0025] Such as figure 1 In the shown embodiment, a squirrel-cage rigid jumper includes a jumper 6 suspended between the line conductors 1 arranged on both sides of the strain tower, and the jumper 6 is provided with multi-split spacers 3 , the multi-split spacer 3 adopts a six-split spacer, and the middle part of the six-split spacer set in the middle section of the jumper 6 is provided with a through hole 4, and the steel pipe 2 passes through the through hole 4 to form a rigid part of the jumper 6, and the steel pipe 2 is provided with There is a suspension 5, which fixes the steel pipe 2. The suspension 5 can be connected in series with a diagonal tie rod or a jumper. The suspension 5 is provided with insulators. The steel pipe 2 can be divided into multiple sections, each The steel pipes 2 are connected by flanges t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com