Closed type sliding following oil receiving device applied to oil return of hydrostatic guideway

A hydrostatic guideway, closed technology, used in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve problems such as hindering the return of hydraulic oil, increasing costs, pressure difference, etc., to ensure the effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

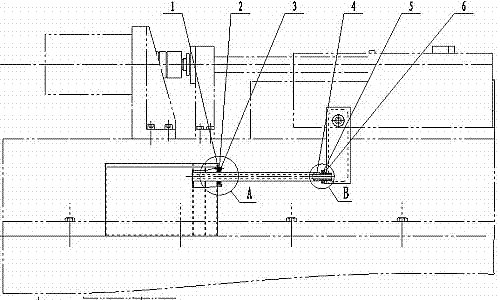

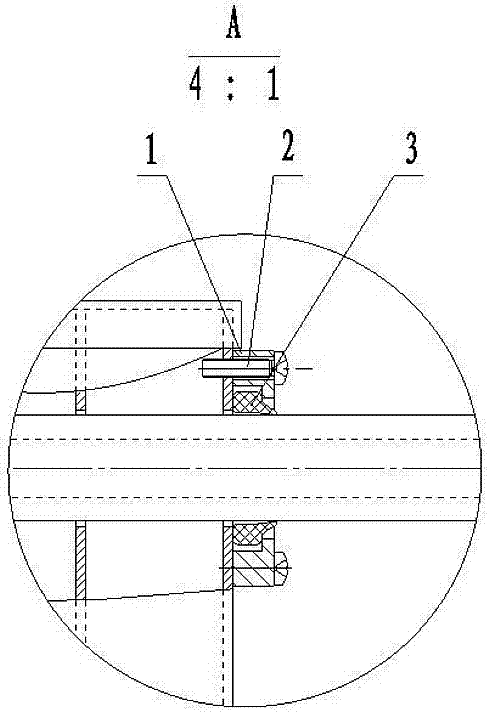

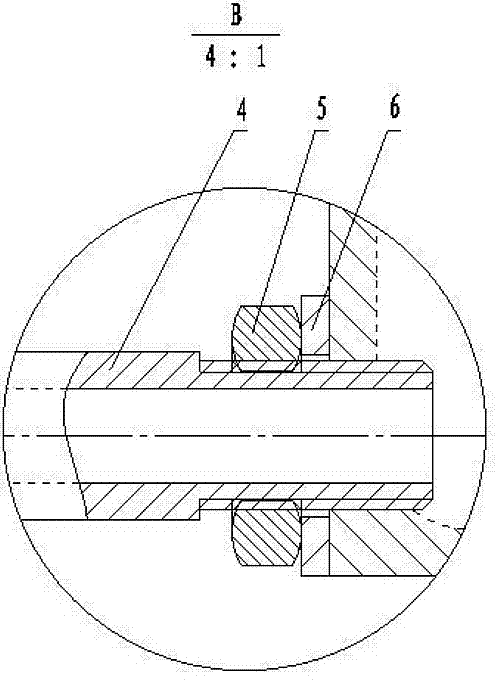

[0012] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the present invention provides a slide-following oil-receiving device for returning oil to a hydrostatic guide rail, including figure 2 The dustproof sealing ring gland (1), the gland fixing screw (2), the dustproof sealing ring (3), the oil delivery pipe (4), the fine tooth lock nut (5), the combined gasket (6), image 3 The static pressure guide rail slide table (7), sealing combination pad (8), oil receiving transition screw (9), oil receiving box (10), oil receiving tank cover (11), oil receiving tank (12), oil receiving tank fixing Screws (13), bed (14).

[0013] The oil receiving box (10) communicates with the oil outlet of the hydrostatic guide rail slide (7) through the oil receiving transition screw (9), and fixes the oil receiving box (10) and the hydrostatic guide rail sliding table (7), and through the sealing combination The gasket (8) is sealed so that the hydraulic oil at the oil ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com