Reclaimed plastic composite enhanced foaming mold plate and production method

A composite reinforced and recycled plastic technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problem of poor rigidity, anti-ultraviolet performance and thermal expansion and contraction can not be widely promoted Problems such as poor nailability, long service life, low cost, and improved bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

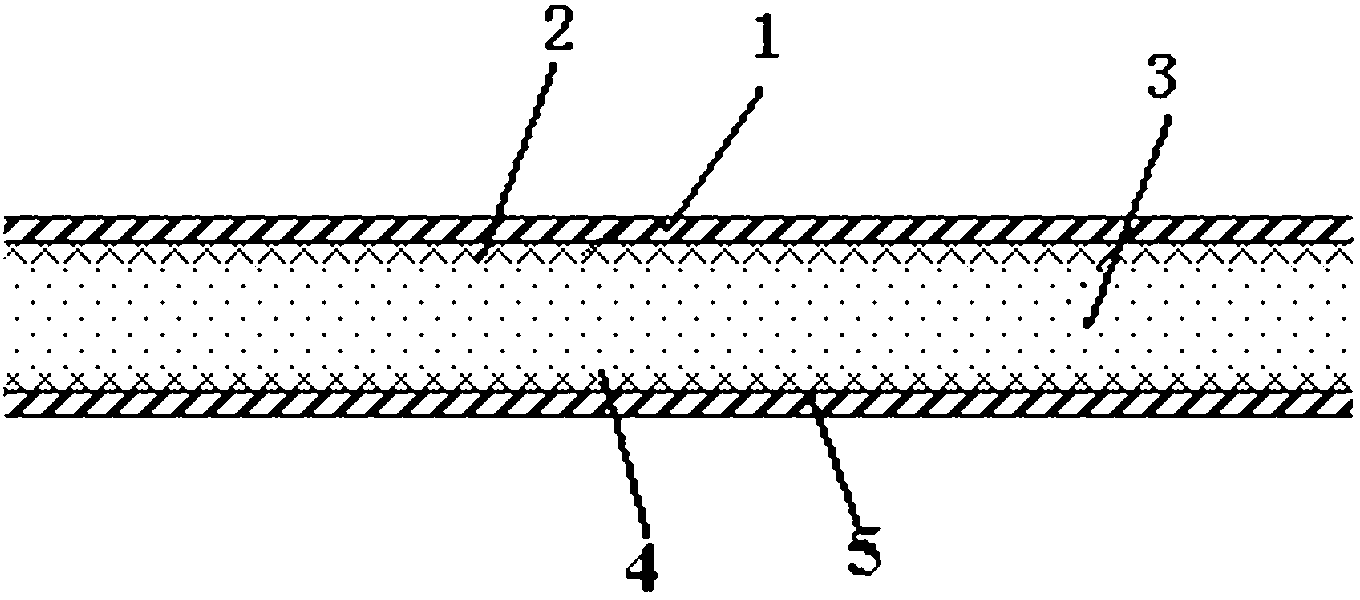

[0054] A recycled plastic composite reinforced foam template, including a thickness of 12-15mm and a capacity of 0.3-0.8g / cm3 The middle foam layer 3 is laid with an upper reinforcement layer 2 on the upper end surface of the middle foam layer 3, and an upper skin layer 1 is compounded on the upper reinforcement layer 2; The reinforcement layer 4 is compounded with the lower skin layer 5 on the lower reinforcement layer 4; the upper skin layer 1, the upper reinforcement layer 2, the foam layer 3, the lower reinforcement layer 4 and the lower skin layer 5 form an integral structure with a thickness of 14-60mm , the bulk density is 0.6-6.82 g / cm 3 .

Embodiment 2

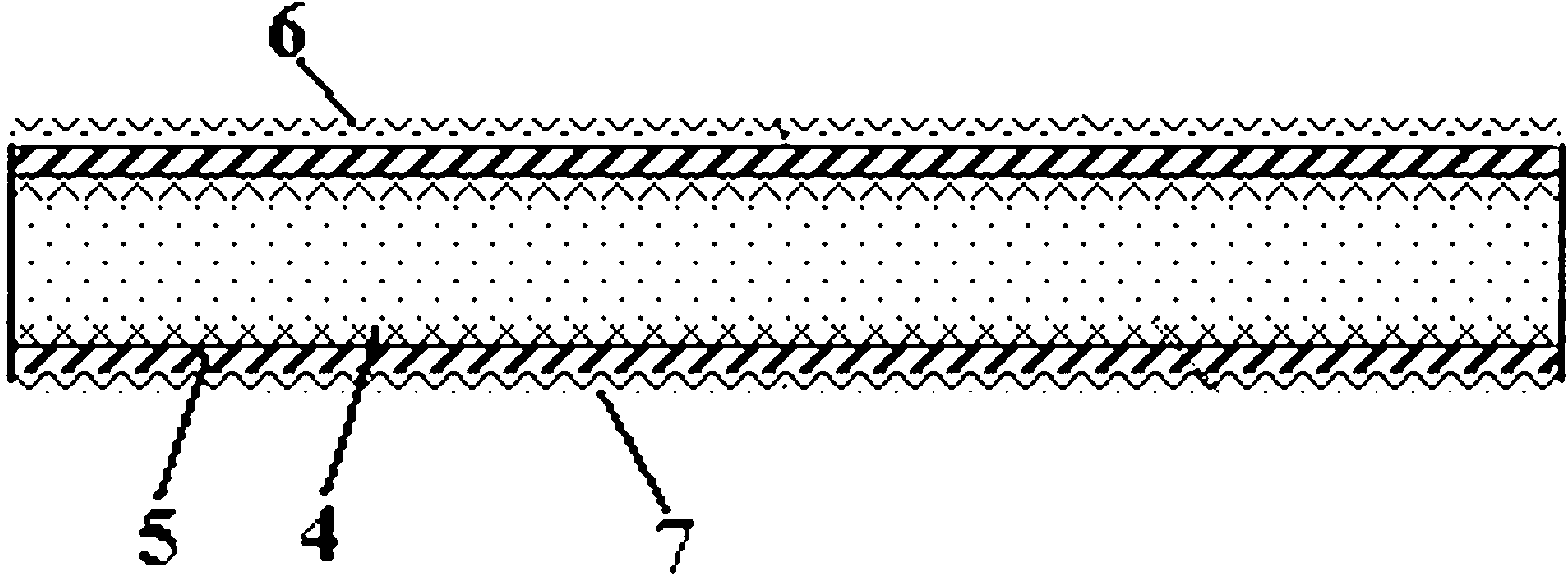

[0056] A recycled plastic composite reinforced foam template described in Embodiment 2 is basically the same in structure as Embodiment 1, the difference is that: the upper end surface of the upper skin layer 1 is compounded with an upper anti-slip layer 6, and the lower skin layer The lower end face of 5 is compounded with lower anti-skid layer 7.

[0057] The epidermis thickness in embodiment one and two is 0.8-1.2 mm, and bulk density is 1-1.2 g / cm 3 The reinforced layer is steel wire mesh or glass fiber mesh; the anti-slip layer is 2-3 mm thick, and is composed of chlorinated polyethylene elastomer mixed with 40-80 parts of 20-30 mesh quartz sand, and then hot extruded on the composite skin layer.

Embodiment 3

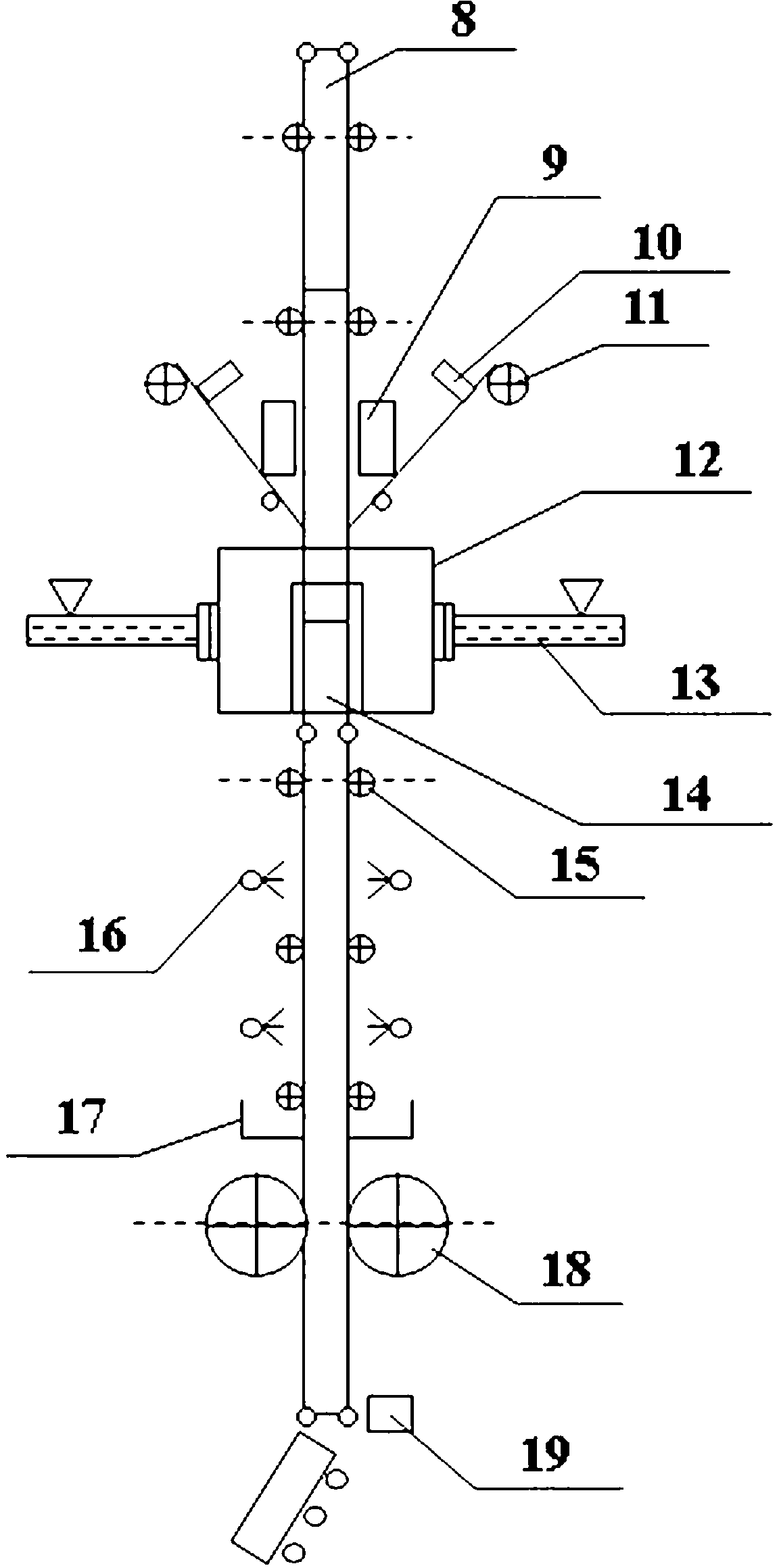

[0059] A recycled plastic composite reinforced foam template and production method, comprising the following steps:

[0060] 1. Take 100 parts of recovered waste plastic PC, ABS or SBS, add 3-5 parts of MAN and 0.05-0.3 parts of DCP, extrude through a Φ75 parallel twin-screw extruder, and cut into pellets after water cooling to make PC, ABS or The grafted modified raw materials of SBS are stored separately for subsequent use;

[0061] 2. Raw materials for preparing the middle foam layer and the skin layer:

[0062] According to the ingredient ratio of PC:ABS:PET=10-30:55-70:5-10, take PC, ABS, SBS prepared in step 1, add 5-7 parts of phase solvent, and pass through parallel twin-screw extruder Hot extrusion graft modification, and granulation for later use; extrusion temperatures were 126, 131, 145, 168, 196, 212, 236, 251°C;

[0063] 3. Prepare the middle foam layer:

[0064] Take the raw material prepared in step 2, add 0.2-1.5 parts of foaming agent, mix evenly, use SJ-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com