Body frame structure of motorcycle

A body frame and motorcycle technology, applied in the field of body frame structure, can solve the problems of inability to improve the rigidity of the body frame, torsional rigidity, low stiffness of the pivot plate, etc., and achieve the effect of increasing rigidity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

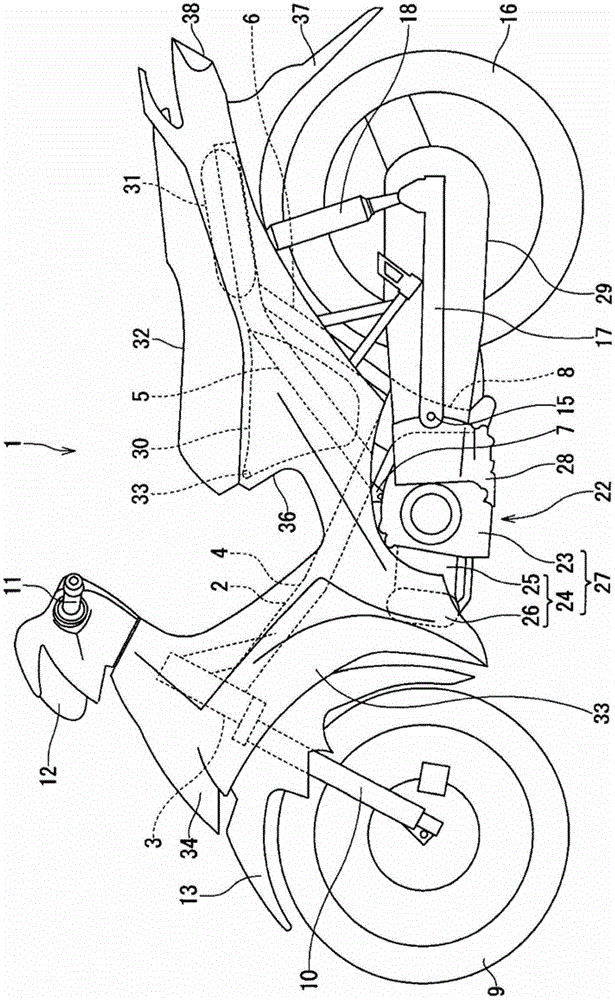

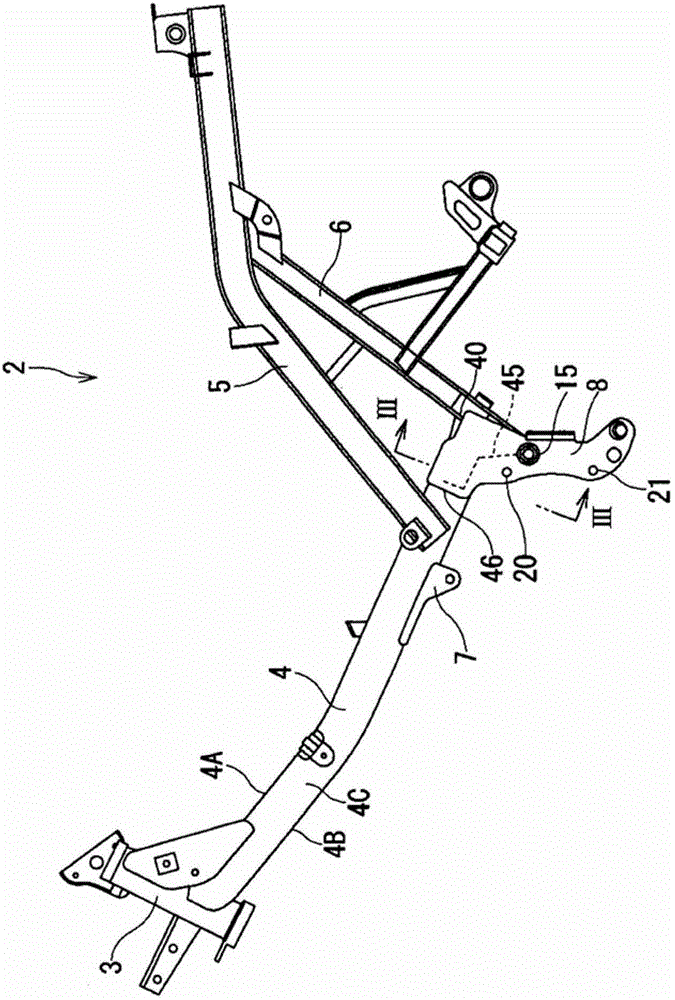

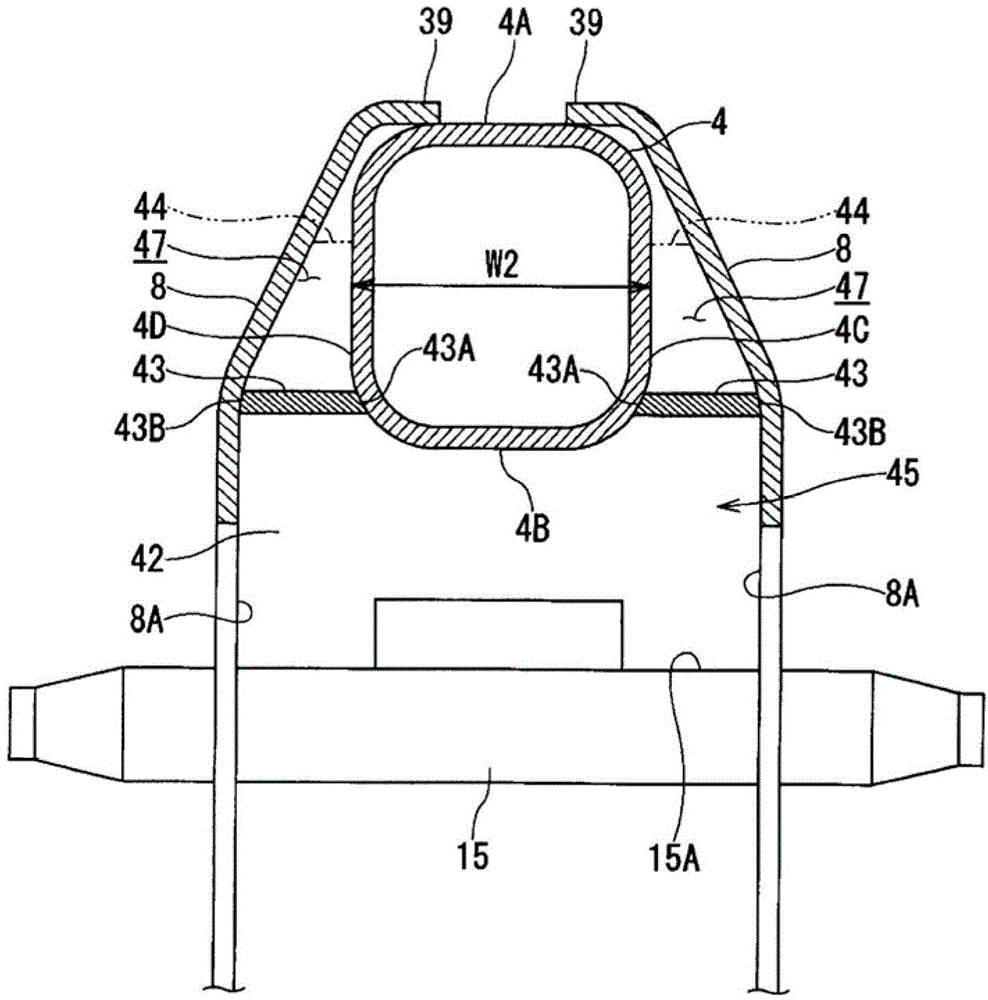

[0024] Hereinafter, embodiments for carrying out the present invention will be described with reference to the drawings. It is further to be noted that terms such as "up", "down", "right", "left", etc. referring to directions or the like refer to the illustrations in the drawings or figure 1 The actual arrangement shown is used here.

[0025] refer to figure 1 and 2 , the motorcycle 1 has a body frame 2 of the lower bone type, and in the body frame 2, a main frame 4 extends downward from a head pipe 3 located at the front head in a rearward tilting direction, and a pair of left and right rear frames (seat rails 5 ) extends obliquely upward in the rearward direction from a portion near the rear end of the main frame 4 , and a rear frame (seat post 6 ) supporting the seat rail 5 is arranged on the rear side of the seat rail 5 . In addition, to the main frame 4, a front engine support frame 7 is attached to an adjacent portion of the connecting portion connected to the seat ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com