Technological opening-closing bomb mould for explosive loading of warhead

A warhead and process technology, which is applied in the field of opening and closing ammunition molds for charging, can solve the problems of inconvenient detection and inability to open the warhead mold, and achieve the effect of convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

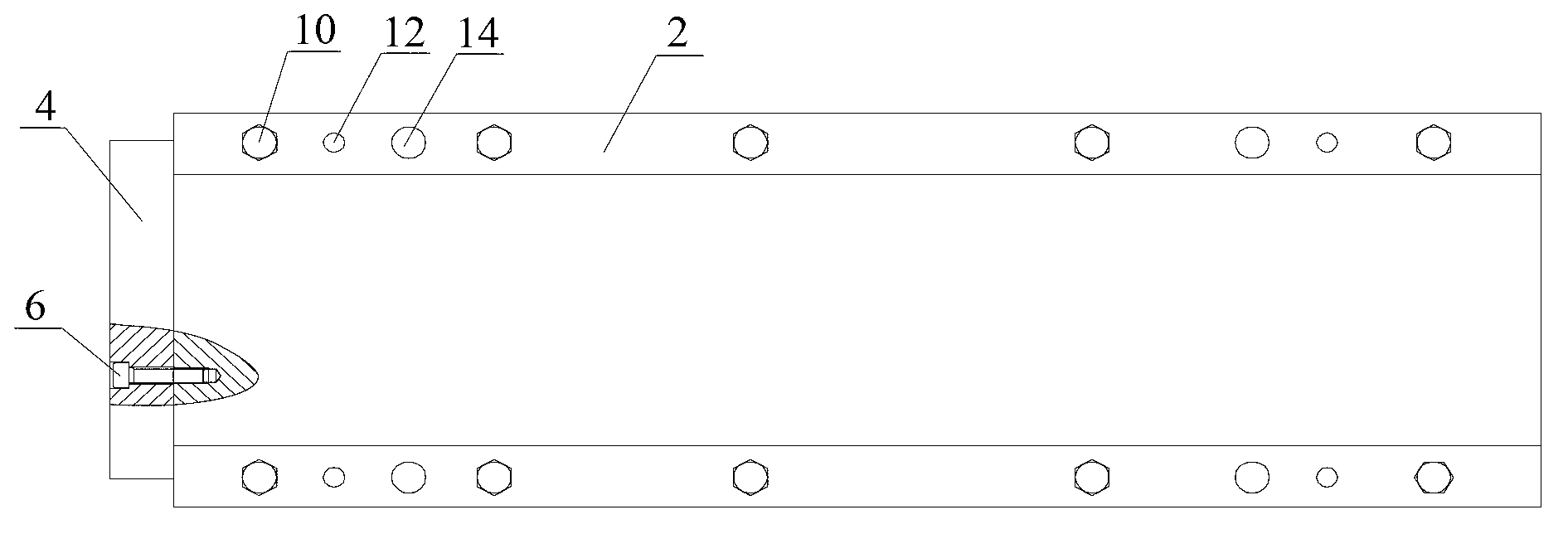

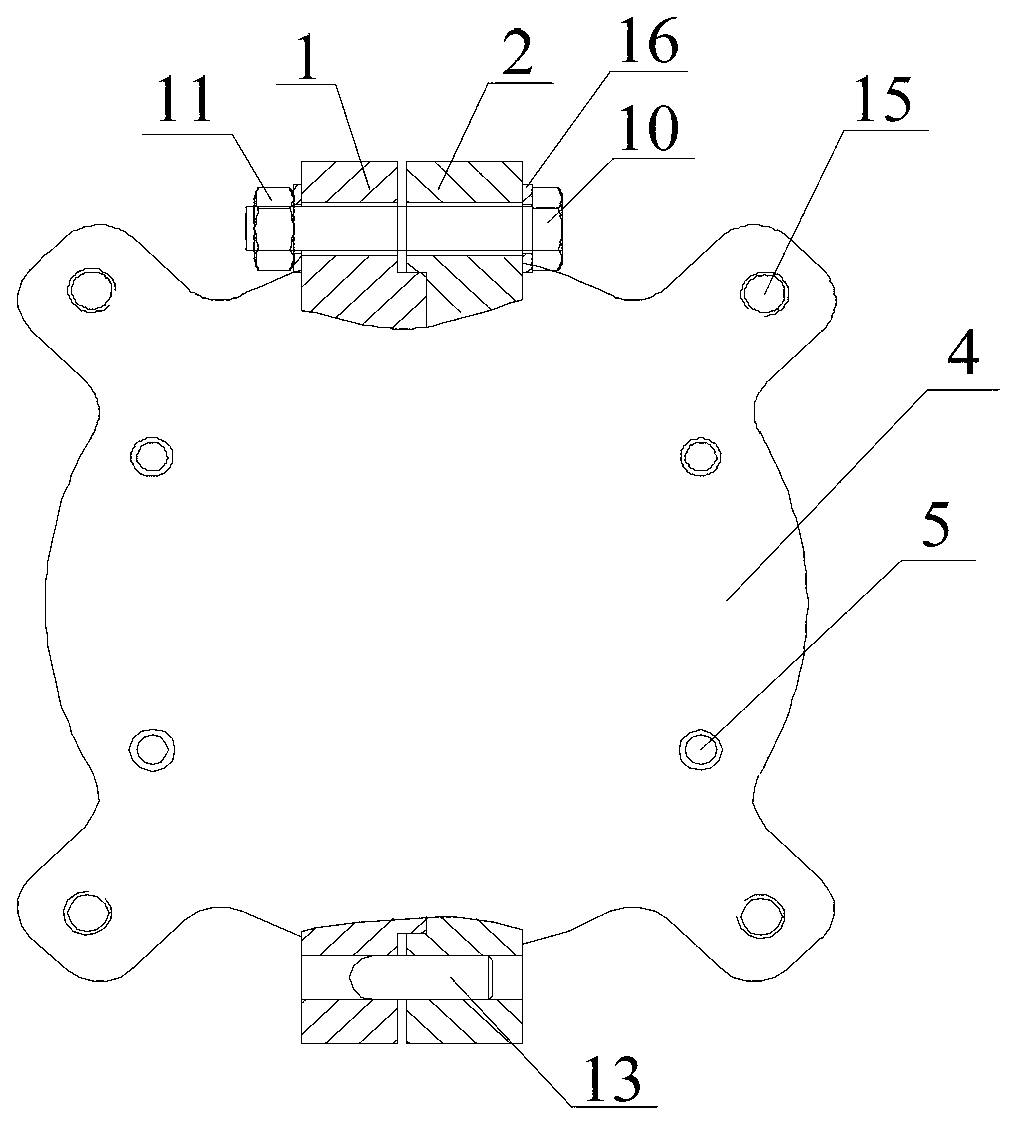

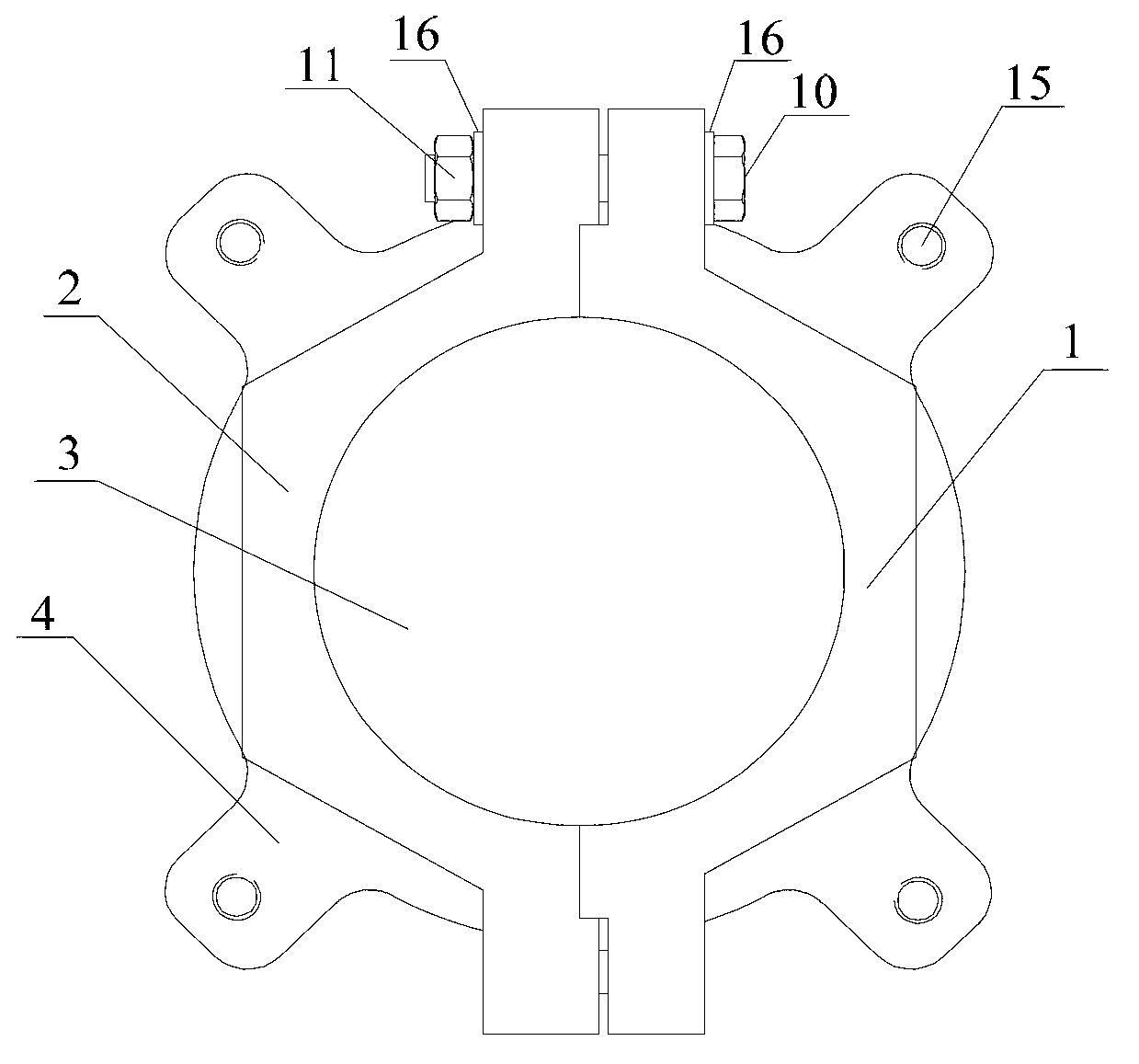

[0035] Such as Figure 1~6 As shown, the present invention mainly consists of a mold body having an opening at one end and a cavity inside. The overall shape of the mold cavity is cylindrical, and the bottom of the mold cavity is hemispherical. The overall shape of the mold cavity is the same as that of the warhead, so that explosives can be poured into the mold cavity and formed into a charge body of a desired shape. In order to facilitate pouring and molding, the bottom of the mold cavity needs to be closed, that is, the other end of the mold body is a closed end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com