Bracing type single-edge bolt fastener

A unilateral bolt and fastener technology, applied in the direction of connecting components, pins, mechanical equipment, etc., can solve the problem that bolts cannot be fastened unilaterally, achieve good fastening effect, improve joint bearing capacity, and high joint reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The structure of the unilateral bolt fastener in this embodiment is set to:

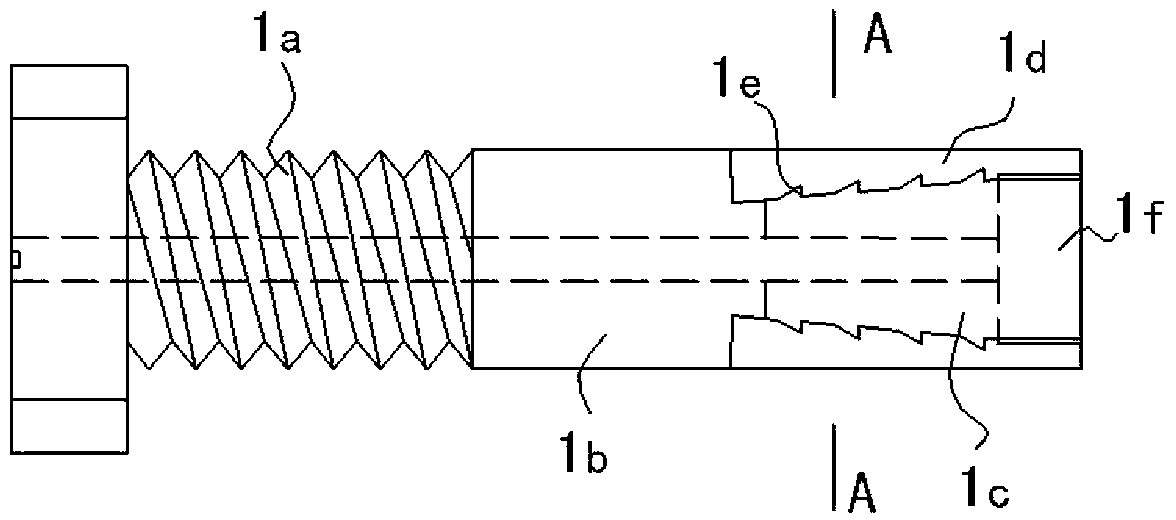

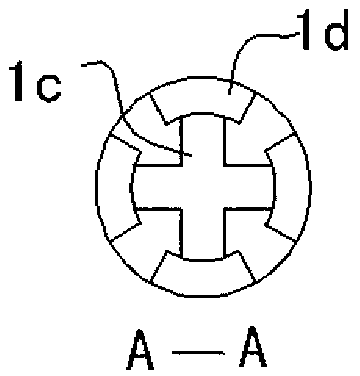

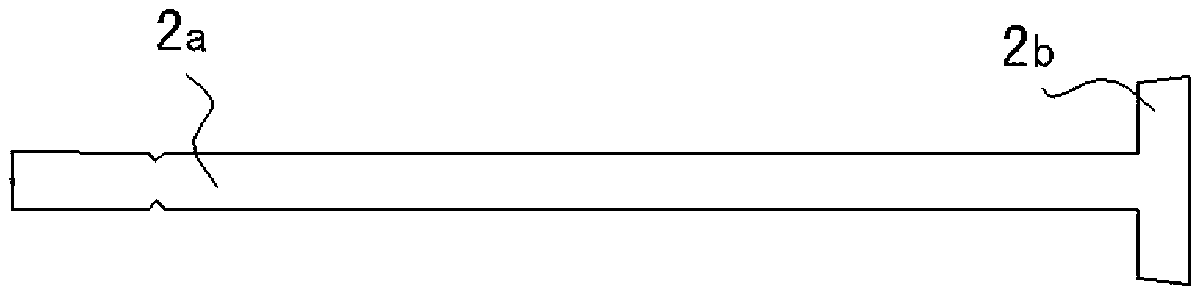

[0020] Such as Figure 1a and Figure 1b As shown, a screw rod with an axial center through hole is provided, the tail section of the screw rod is a threaded rod 1a matched with the nut 3, the middle section is a polished rod 1b, and the front section is a support head 1c; the support head 1c has a hollow inner cavity to support The side wall of the head 1c opens at the symmetrical position of the "ten", forming four elastic flaps 1d that can be stretched in an umbrella shape. The inner side wall of the elastic flap 1d is a slope surface, and the slope surface makes the front end of the hollow cavity have a diameter greater than Tail diameter; in specific implementation, after inserting the pull rod 2a from the side where the supporting head 1c is located, the sealing head 1f is screwed onto the supporting head 1c, so that the bolt becomes a whole, and the sealing head 1f and the supporting he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com