A torsion shear type unilateral self-tightening bolt fastener

A technology for unilateral self-tightening bolts and fasteners, applied in the direction of threaded fasteners, screws, connecting components, etc., can solve the problem that bolts cannot be unilaterally tightened, and achieve excellent tightening effect, easy operation, The effect of improving the bearing capacity of nodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

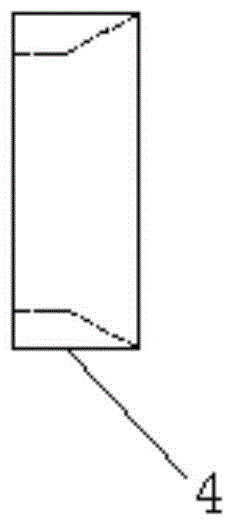

[0025] A new torsional shear high-strength unilateral self-tightening bolt fastener, including a torsional shear high-strength bolt 1 with a torx head 1-2, a nut 2, a second sleeve 3, a first sleeve 4 and a gasket 5;

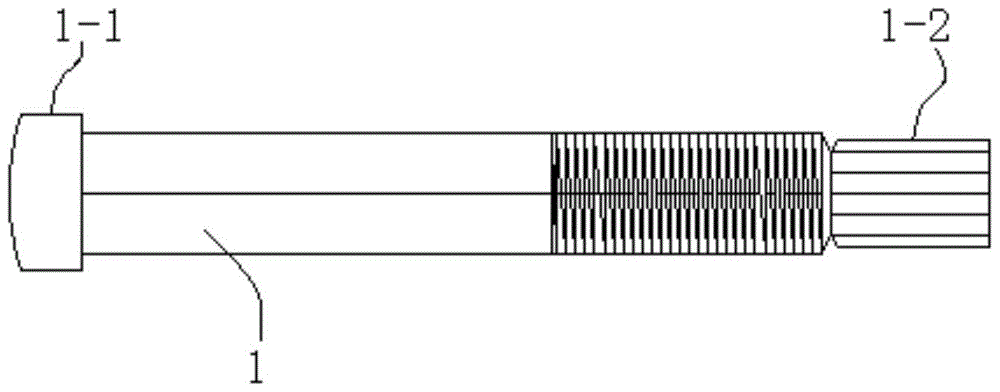

[0026] Such as figure 1 As shown, one end of the torsional shear type high-strength bolt 1 has a bolt head 1-1 larger than the screw rod, and the other end has an easy-to-shear torx head 1-2, and there is a thread between the torx head 1-2 and the bolt head 1-1.

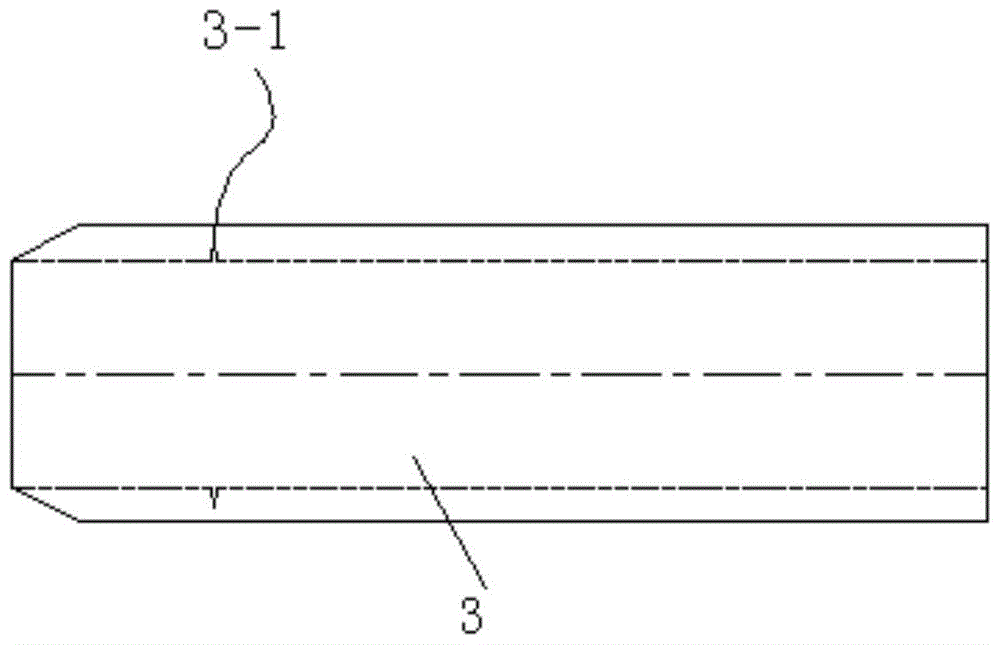

[0027] Such as figure 2 As shown, the second sleeve 3 is made of steel with a low yield point, and the outer side of one end of the second sleeve 3 is wedge-shaped, and the inner cavity of the second sleeve 3 is provided with an annular groove 3 in the middle -1, the yield strength of the second sleeve 3 is between 100MPa and 300MPa, the critical stress for plastic deformation at the annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com