Rotary closed type unilateral bolt fastener

A technology of unilateral bolts and fasteners, applied in the direction of connecting components, pins, mechanical equipment, etc., can solve the problem that bolts cannot be fastened unilaterally, and achieve the effect of good fastening effect, convenient production and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The structural settings of the rotary closed unilateral bolt fastener in this embodiment include:

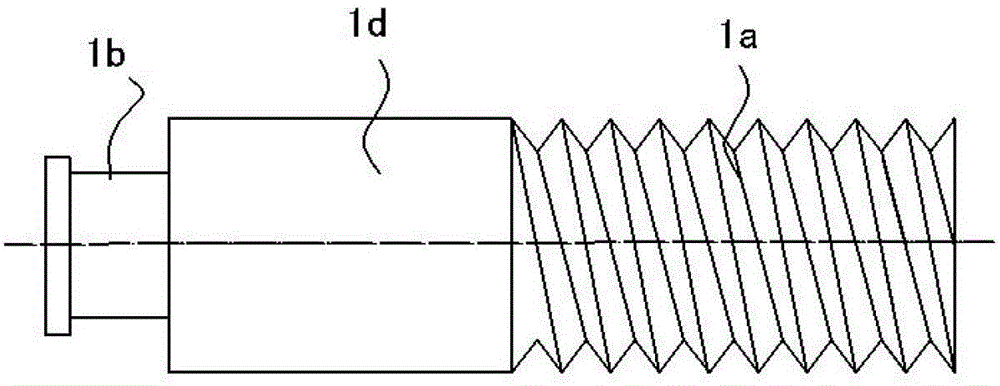

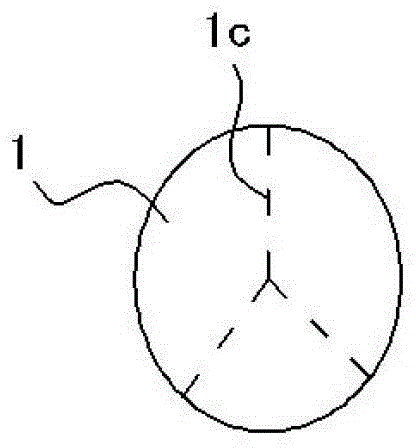

[0027] Such as Figure 1a and Figure 1b As shown, the front body of the screw 1 is set as a threaded rod 1a, the middle part is a polished rod 1d, and the tail of the screw 1 is a polished rod journal section 1b; the front end of the screw 1 is marked with an installation prompt line 1c at an interval of 120°; The threaded 1a bar of nut 3 and screw rod 1 is threadedly engaged (as Figure 5a shown);

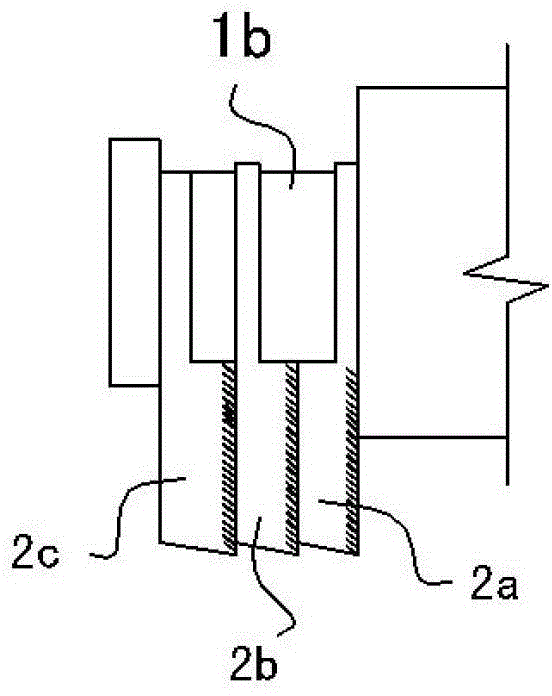

[0028] Such as Figure 2a and Figure 2b As shown, the three ring cards 2 are respectively the front card 2a, the middle card 2b and the tail card 2c, and the ring card 2 is set on the tail journal section 1b of the screw with a ring body; the front end card 2a and the middle card 2b can be placed on the The journal section rotates freely, and the tail clip 2c is fixedly connected with the screw rod 1;

[0029] Such as Figure 3a and Figure 3b As shown, the side view...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com