A simple split assembly bolt fastener

A bolt fastener and assembly technology, applied in the direction of threaded fasteners, screws, connecting components, etc., can solve the problems of difficult on-site installation and poor fastening effect, eliminate hidden dangers, and facilitate batch processing and manufacturing , The effect of simple assembly operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

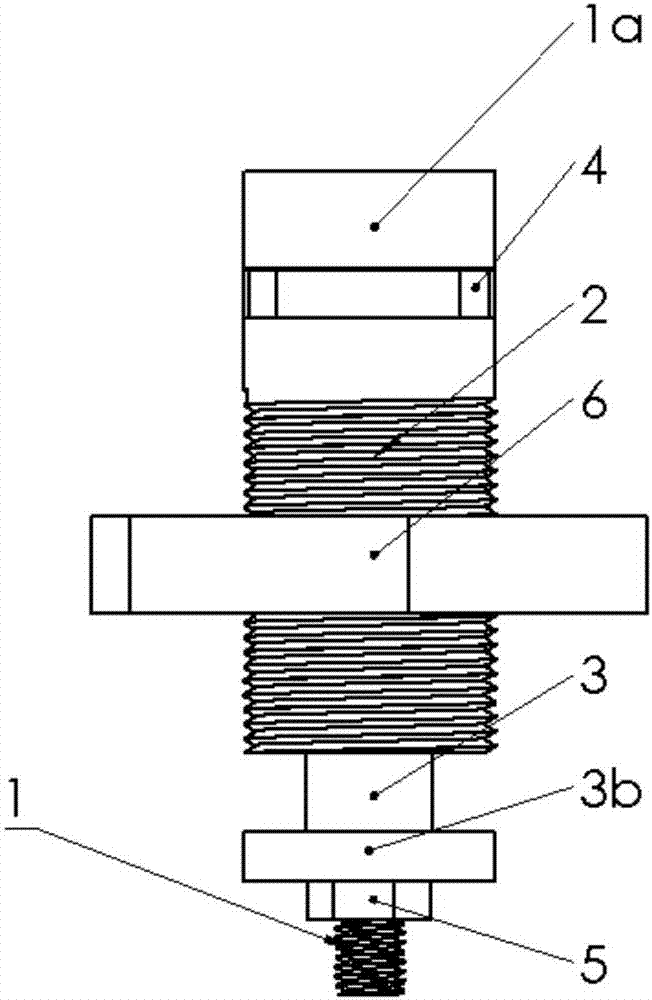

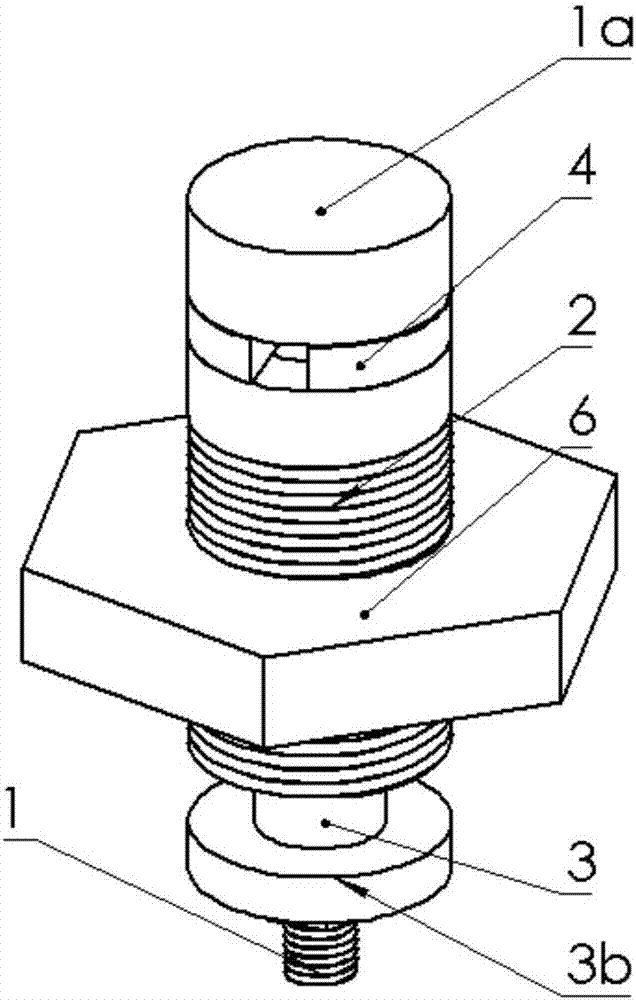

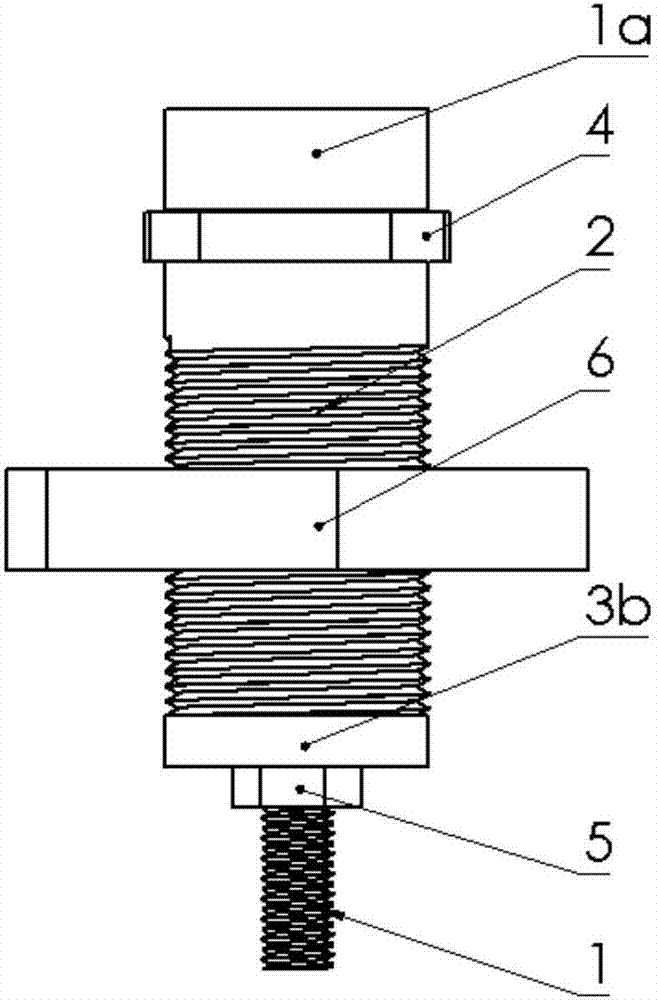

[0058] Such as Figure 1A-6BAs shown, the simple split assembly bolt fastener described in the present invention includes an inner screw rod 1, an outer sleeve 2, an inner sleeve 3, a fan-shaped support assembly 4, a small nut 5 and a large nut 6; wherein the outer sleeve 2 and the inner sleeve 3 are sequentially set outside the inner screw 1 and the inner screw 1, the outer sleeve 2 and the inner sleeve 3 are coaxial.

[0059] One end of the internal screw 1 is provided with a support head 1a, the other end is provided with a thread, and the middle section is a polished rod; the support head 1a of the internal screw 1 is provided with the axial direction of the internal screw 1 as the center, and at intervals of 120°, 3 evenly distributed fittings groove 1b, and an annular matching groove 1c centered on the axial direction of the internal screw 1.

[0060] Among them, such as Figure 3B As shown, the shape of the matching groove 1b is surrounded by two straight lines and tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com