Displacement detecting device, scale calibrating method and scale calibrating program

A technology of displacement detection and ruler, which is applied in measuring devices, adopting optical devices, converting sensor output, etc., can solve the problems of sensor arrangement spacing limitation, large cost and manpower, and expensive configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, the displacement detection device, the scale calibration method, and the scale calibration program according to the embodiments of the present invention will be described in detail with reference to the drawings.

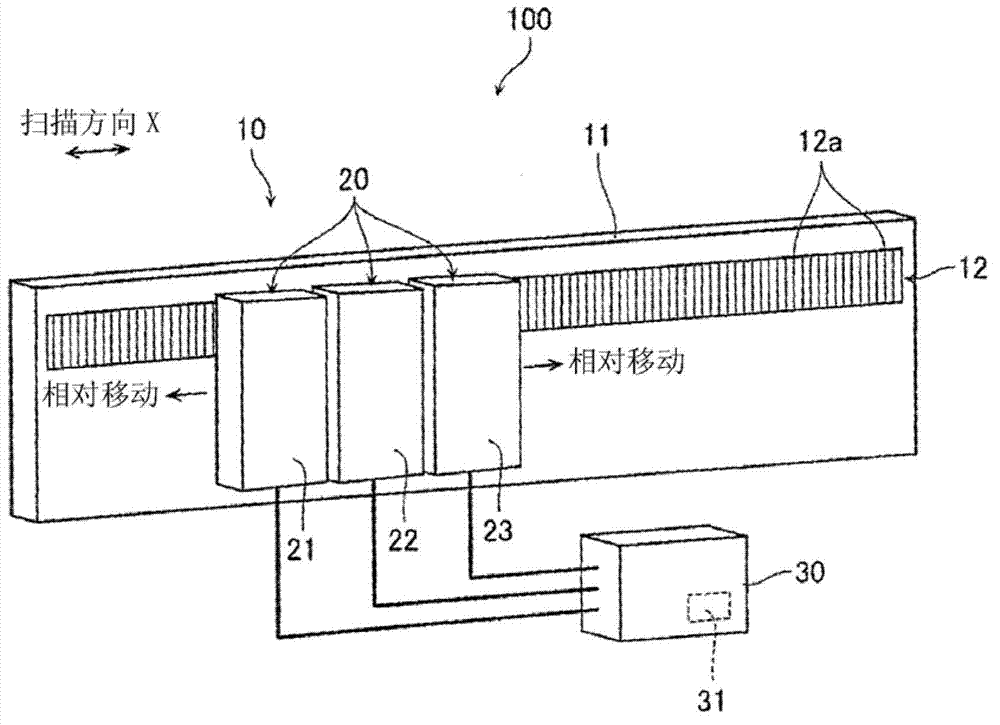

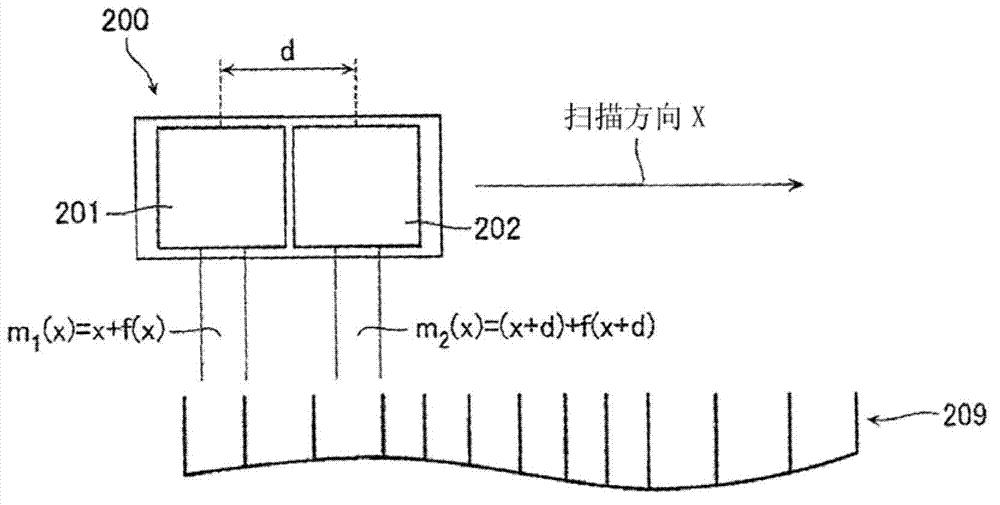

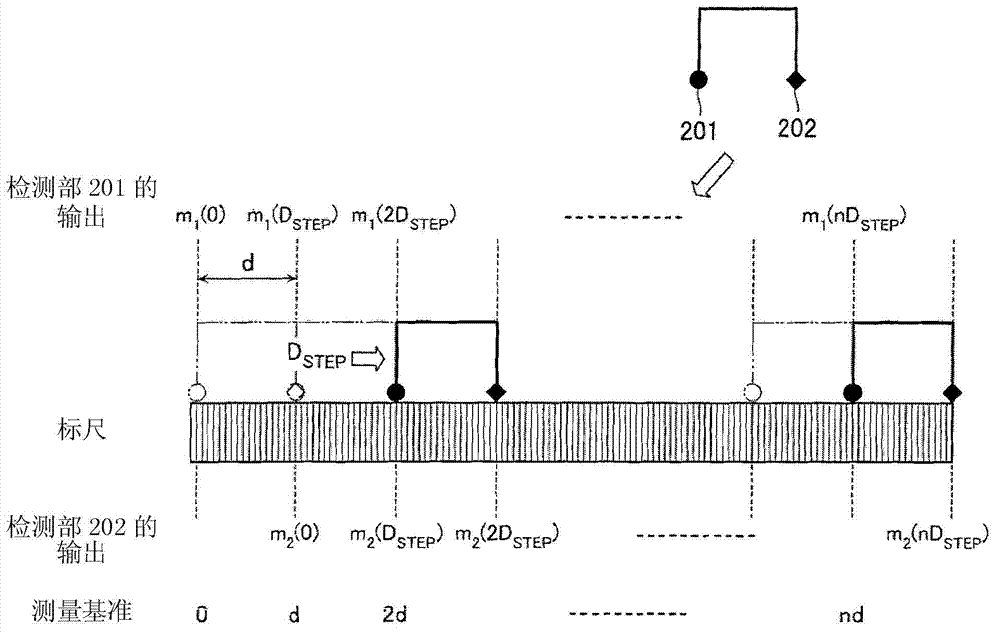

[0028] figure 1 It is a schematic diagram showing the configuration of a photoelectric encoder constituting the displacement detection device according to an embodiment of the present invention. Such as figure 1 As shown, the photoelectric encoder 100 includes a scale 10, a detection unit 20, and a calculation unit 30. For example, in this embodiment, the photoelectric encoder 100 is formed as a reflection type.

[0029] For example, the scale 10 is constituted by a band-shaped scale, and has position information for detecting the positions of the measuring points of the detection sections 21, 22, and 23 (first, second, and third detection sections) constituting the detection unit 20. The scale 10 is installed so that the light rays irradiated from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com