A biaxial high-low cycle composite fatigue test device

A technology of fatigue test and fatigue testing machine, which is applied in the field of biaxial high-low cycle composite fatigue test device, and achieves the effect of less parts and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

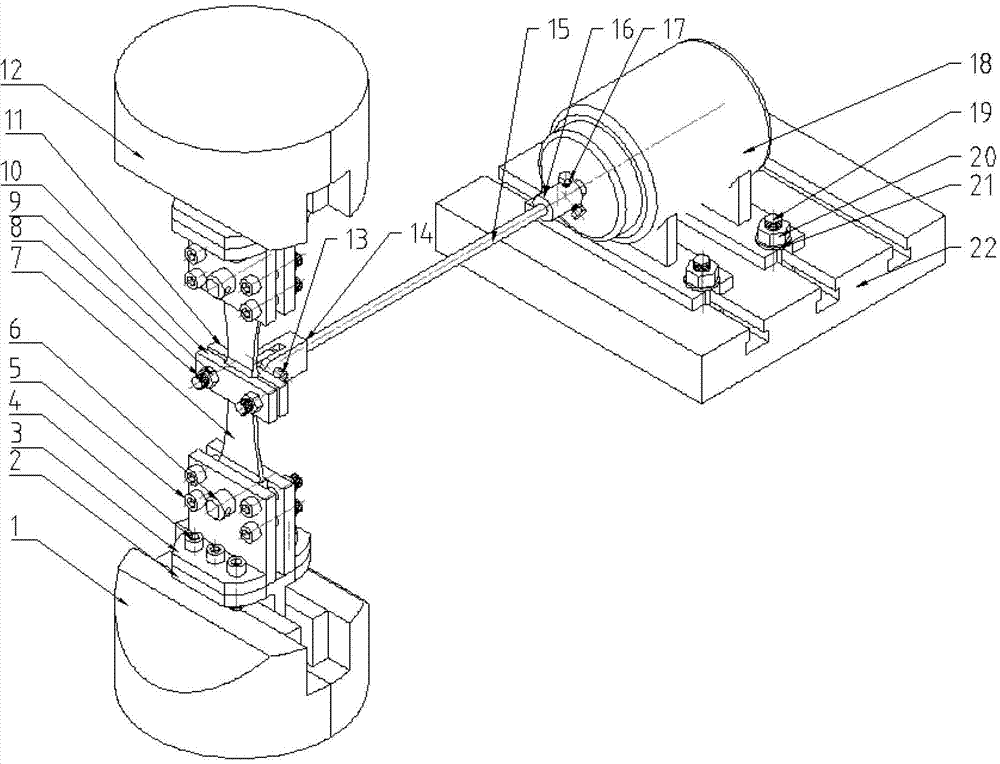

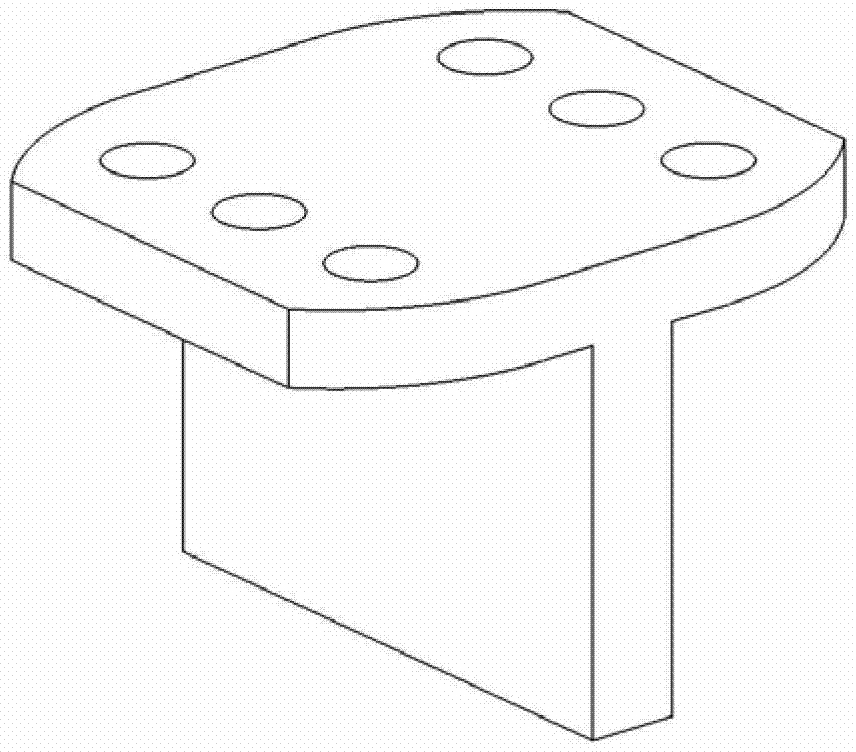

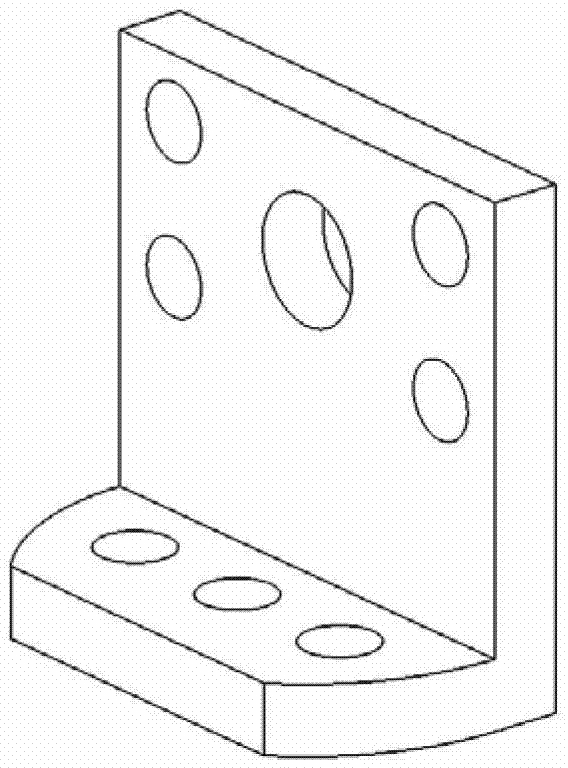

[0044] See figure 1 —— Figure 10 , the present invention is a biaxial high-low cycle composite fatigue test device, the device mainly includes hydraulic fatigue testing machine and upper and lower chucks (1), (12), electromagnetic exciter (18), sample (7) As well as fixtures and positioning connections. The positional connection relationship between them is: the electromagnetic exciter (18) is positioned through the cylindrical connector (16), the connecting rod (15), the U-shaped connector (14) and the middle clamp block in the fixture 2 (11) connection; the middle clamp block 2 (11), the middle clamp block 1 (10) clamp the square mass block convex in the middle of the sample (7) through the inner hexagonal bolt 3 (8) and the outer hexagonal nut 1 (9). platform, the two ends of the sample (7) are connected to the splint (3) in the fixture through the hexagon socket bolt 2 (5) and the large pin (6); the splint (3) is screwed to the flat end of the connector (2) in the fixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com