Practical training teaching robot platform for three-degree-of-freedom motion control system

A motion control system and robot technology, applied in teaching models, instruments, educational tools, etc., can solve the problems of complex equipment and inability for students to debug and program

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

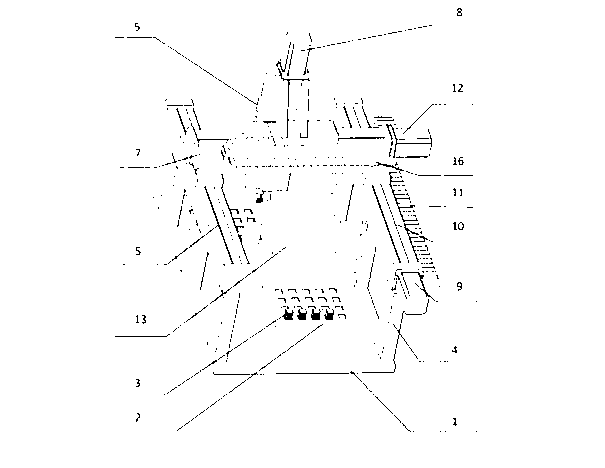

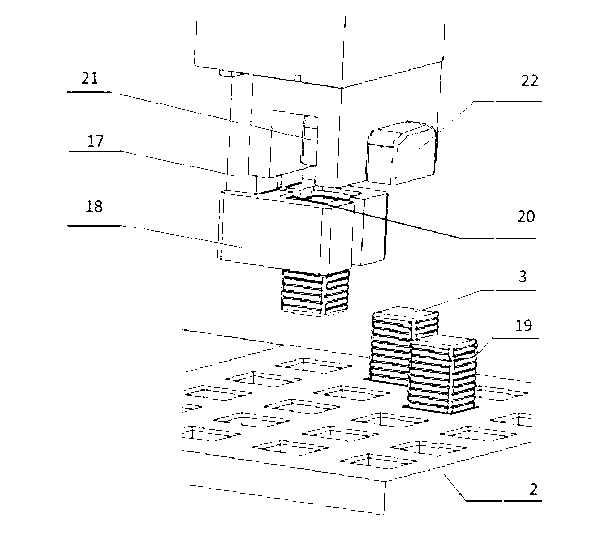

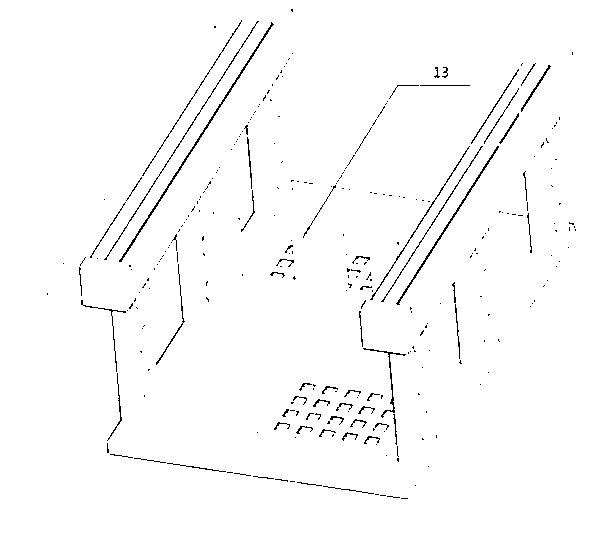

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 shown

[0025] A teaching and training robot platform for a three-degree-of-freedom motion control system of the present invention includes: a bottom plate 1, a four-column or six-column gantry-type bracket 4, an X1 axis 10 of an X-axis motion mechanism, an X2 axis 5, and an X1-axis servo motor 9, Y Axis motion mechanism 7, Y-axis servo motor 12, Z-axis motion mechanism 6, Z-axis servo motor 8, drag chain 11, 15, 16, parallel gripper 17, claw finger 18, sawtooth pattern on the claw finger 20, color Sensor 21, reflective wire harness type laser sensor 22, supporting plate for placing workpieces 2, several workpiece blocks of different colors 3, sawtooth pattern on the workpiece blocks 19, baffle type barrier plate 13, maze alley type barrier plate 24. Composed of multi-axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com