Circular socket connector capable of reliably conducting parts of contact elements and shell

A partial contact, circular socket technology, used in contact parts, connections, parts of connecting devices, etc., can solve problems such as inability to meet reliable contact and conduction, poor reliability, etc., improve grounding reliability, and strengthen anti-vibration. The effect of impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

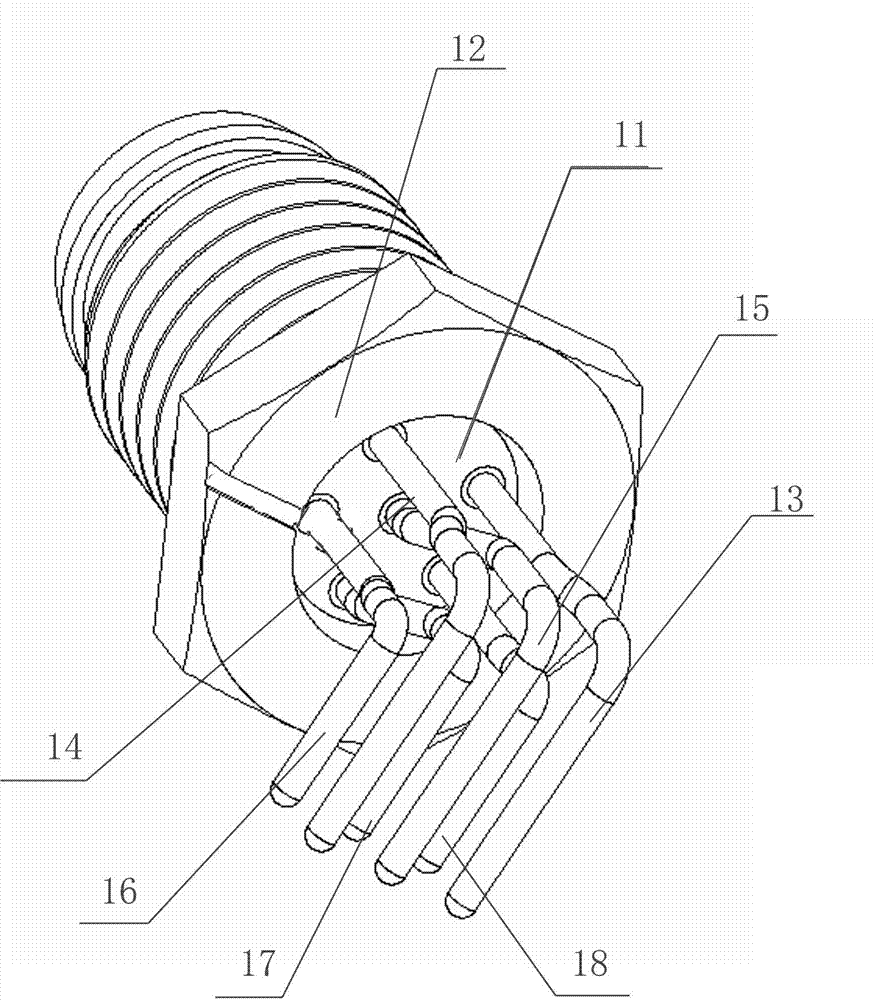

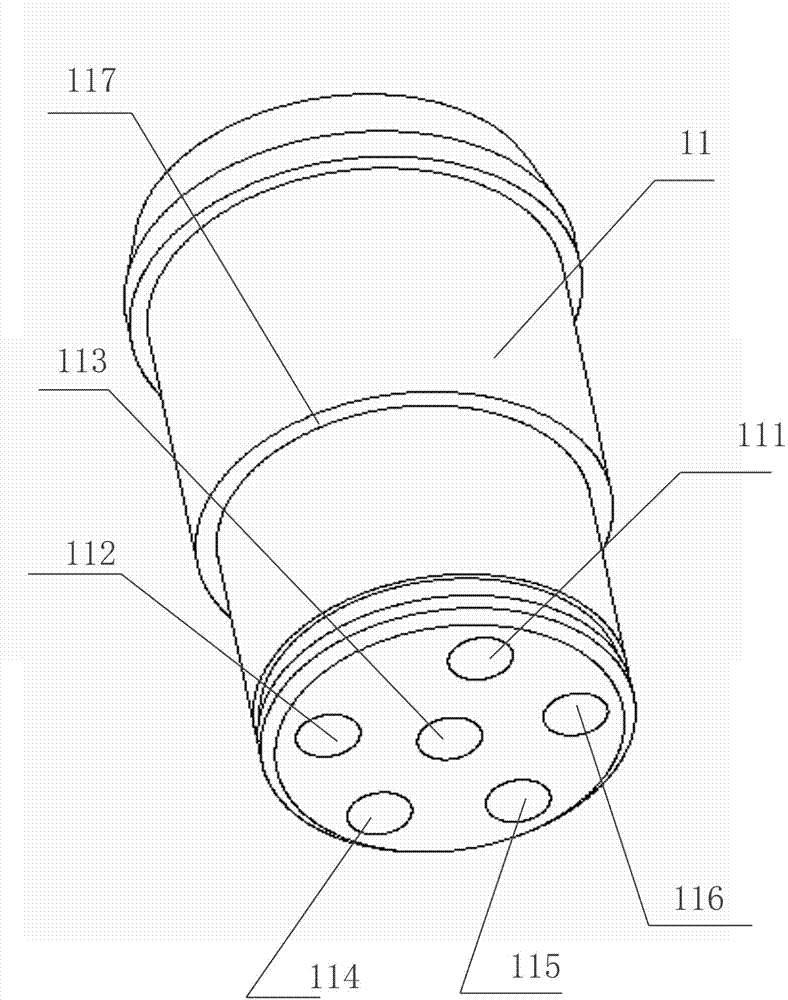

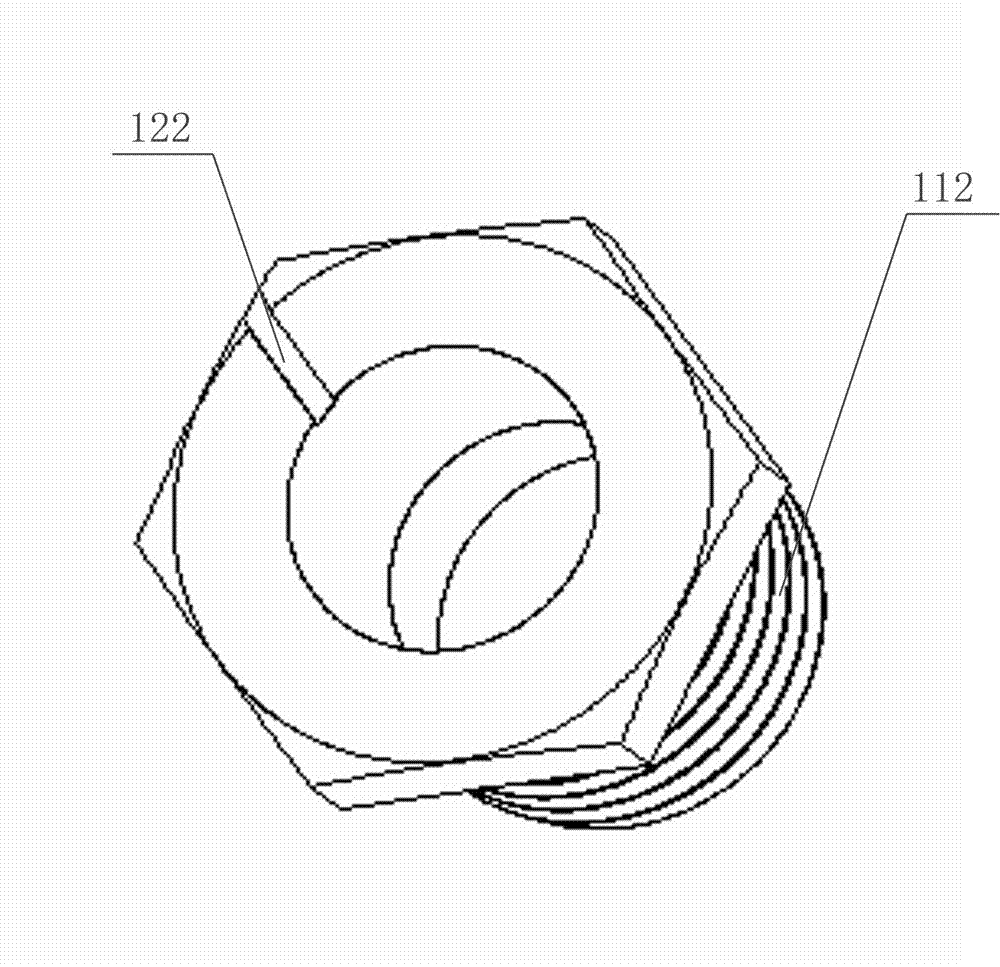

[0018] exist figure 1 , figure 2 , image 3 with Figure 4 Among them, the present invention provides a circular receptacle connector in which part of the contacts is reliably connected to the shell, which includes an insulator 11, a shell 12, a contact I13, a contact II14, a contact III15, a contact IV16, and a contact V17 , contact piece VI18 and connecting wire 19, the insulator 11 is pressed into the shell 12, the outer surface of the insulator 11 is provided with a stepped surface I117, the inner surface of the shell 12 is provided with a stepped surface II121, and the stepped surface I117 is connected to the step The surface II121 is flush, so that the limit function of the insulator 11 when it is pressed into the housing 12 can be realized. On the top of the insulator 11, there are installation holes I111, installation holes II112, installation holes III113, installation holes IV114, installation holes V115 and installation holes Ⅵ116, the installation hole Ⅵ116 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com