A bistable electrostatic switch

A bistable and electrostatic technology, applied in the direction of electrostatic relays/electro-adhesion relays, circuits, relays, etc., can solve the problems of poor shock resistance and vibration performance, large volume and weight, complex processing and packaging technology, etc., to improve the resistance to vibration and shock The effect of performance, small volume and weight, simple processing technology and packaging technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

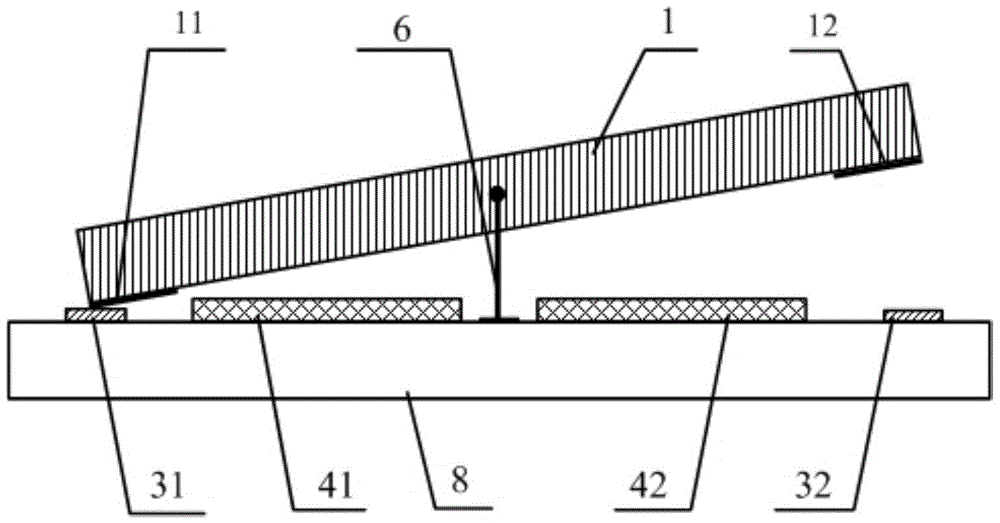

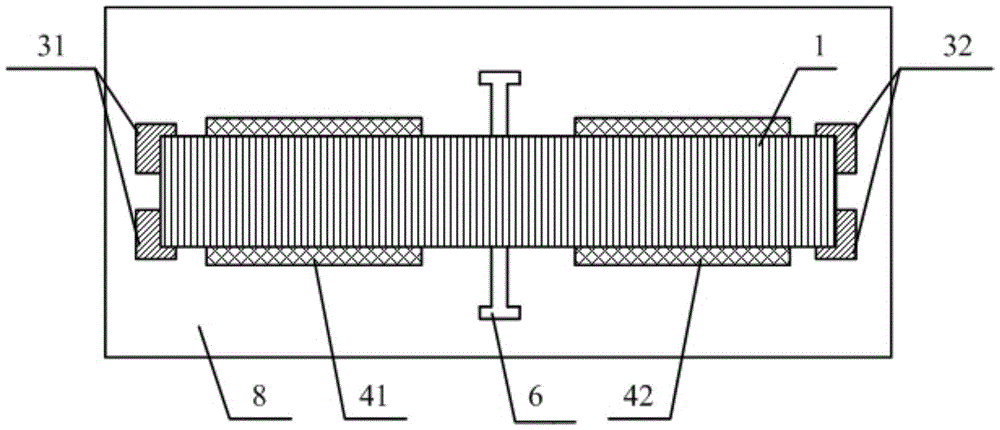

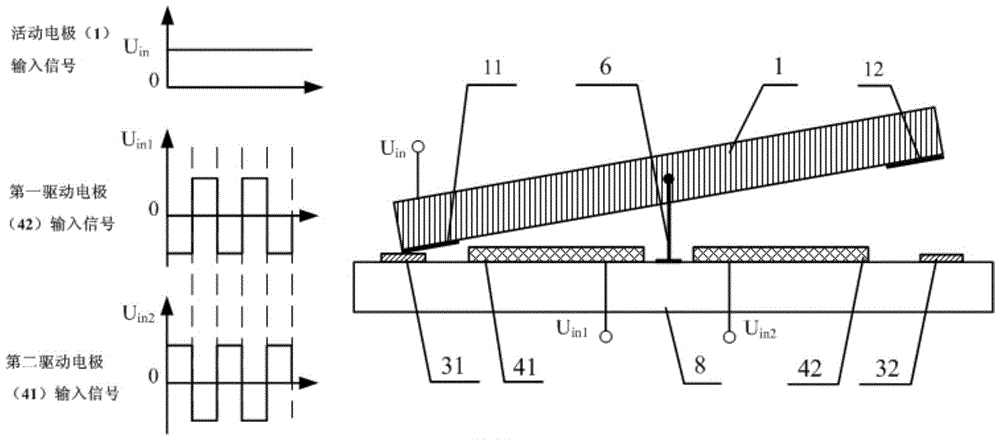

[0032] image 3 It is an embodiment of a unipolar active electrode bistable electrostatic switch, the polarity direction of the first drive electrode 41 and the second drive electrode 42 are opposite, and the active electrode 1 is connected to the external power supply U in connected. External power supply U in It is a power supply with fixed polarity, and the electrical signal U in1 and U in2 opposite polarity. such as U in is positive, then when U in1 positive, U in2 When it is negative, the active electrode 1 is flipped clockwise until the state is maintained; such as U in is positive, then when U in1 negative, U in2 When positive, the active electrode 1 still maintains a stable state. When U in is negative, then when U in1 positive, U in2 When it is negative, the movable electrode 1 turns counterclockwise around the support shaft or support axis until the state remains; in is negative, then when U in1 negative, U in2 When positive, the active electrode 1 st...

Embodiment 2

[0034] Image 6 It is an embodiment of a bipolar active electrode bistable electrostatic switch, wherein the polarity direction of the first active electrode 1a and the second active electrode 1b are opposite, and the first driving electrode 41 and the The second driving electrodes 42 are all connected to the external fixed power supply U in connected. Electrical signal U in1 and U in2 opposite polarity. such as U in is positive, then when U in1 positive, U in2 When it is negative, the active electrode 1 is flipped clockwise until the state is maintained; such as U in is positive, then when U in1 negative, U in2 When positive, the active electrode 1 still maintains a stable state. such as U in is negative, then when U in1 positive, U in2 When it is negative, the active electrode 1 flips counterclockwise until the state remains; when U in is negative, then when U in1 negative, U in2 When positive, the active electrode 1 still maintains a stable state. The switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com