A transmission mechanism for a microwave switch

A microwave switch and transmission mechanism technology, applied to waveguide devices, electrical components, circuits, etc., can solve the problems of difficulty in meeting the transmission requirements of high-power microwave switches and limited reed stroke amplification, and achieve small space occupation and effective improvement. load, and the effect of improving the vibration and shock resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

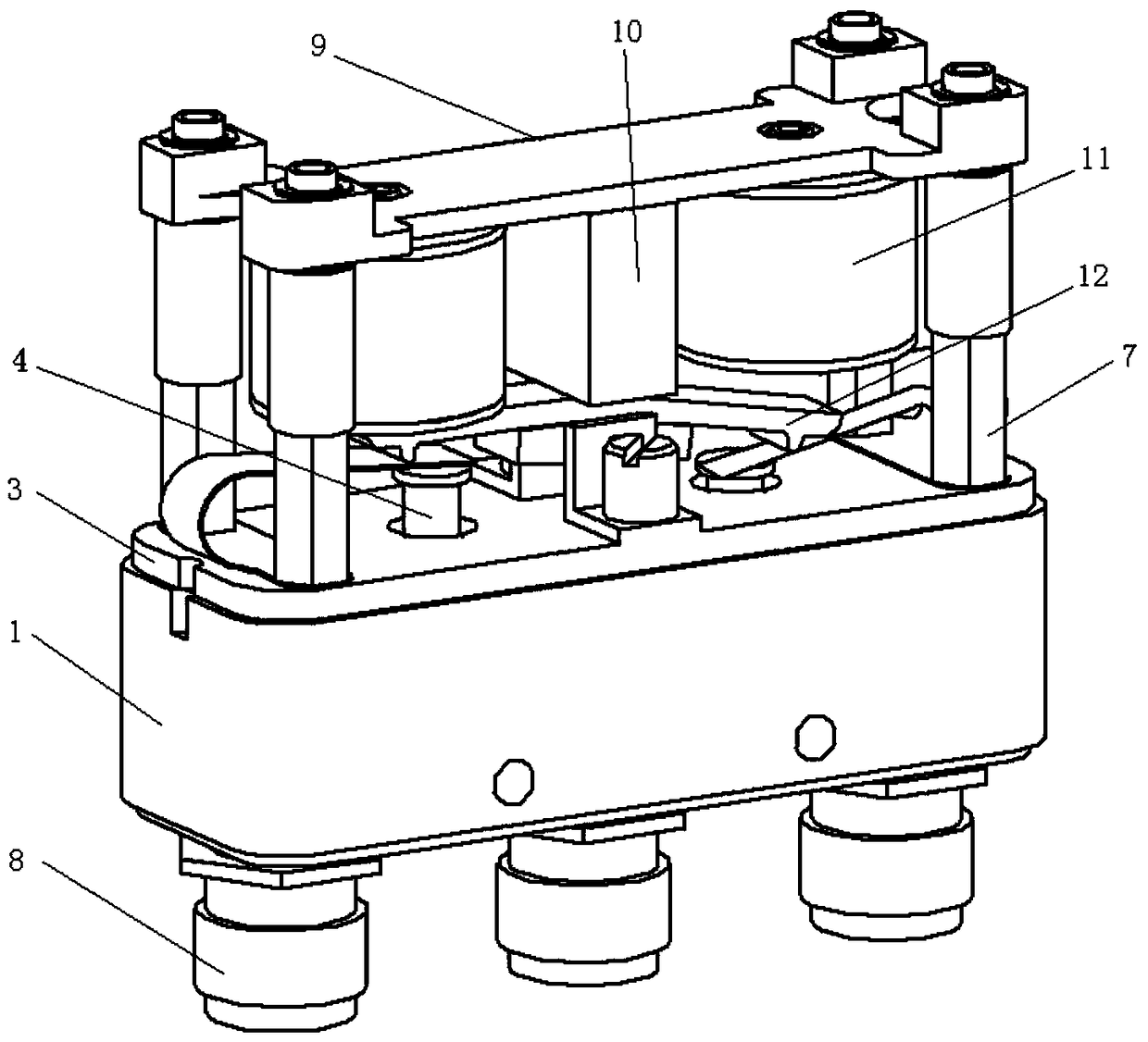

[0029] A transmission mechanism for a microwave switch, such as figure 1 As shown, including electromagnetic group, armature group and guide system,

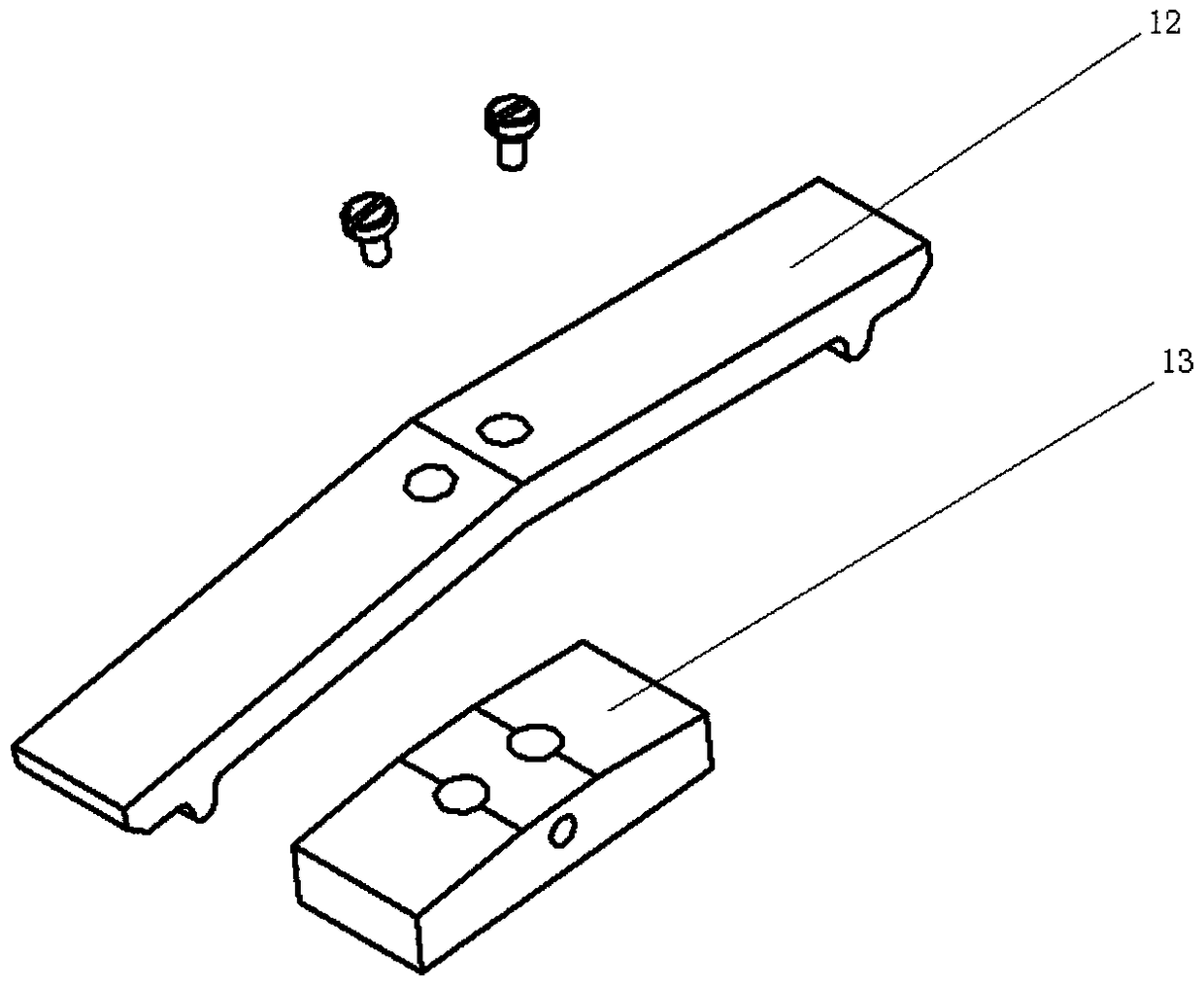

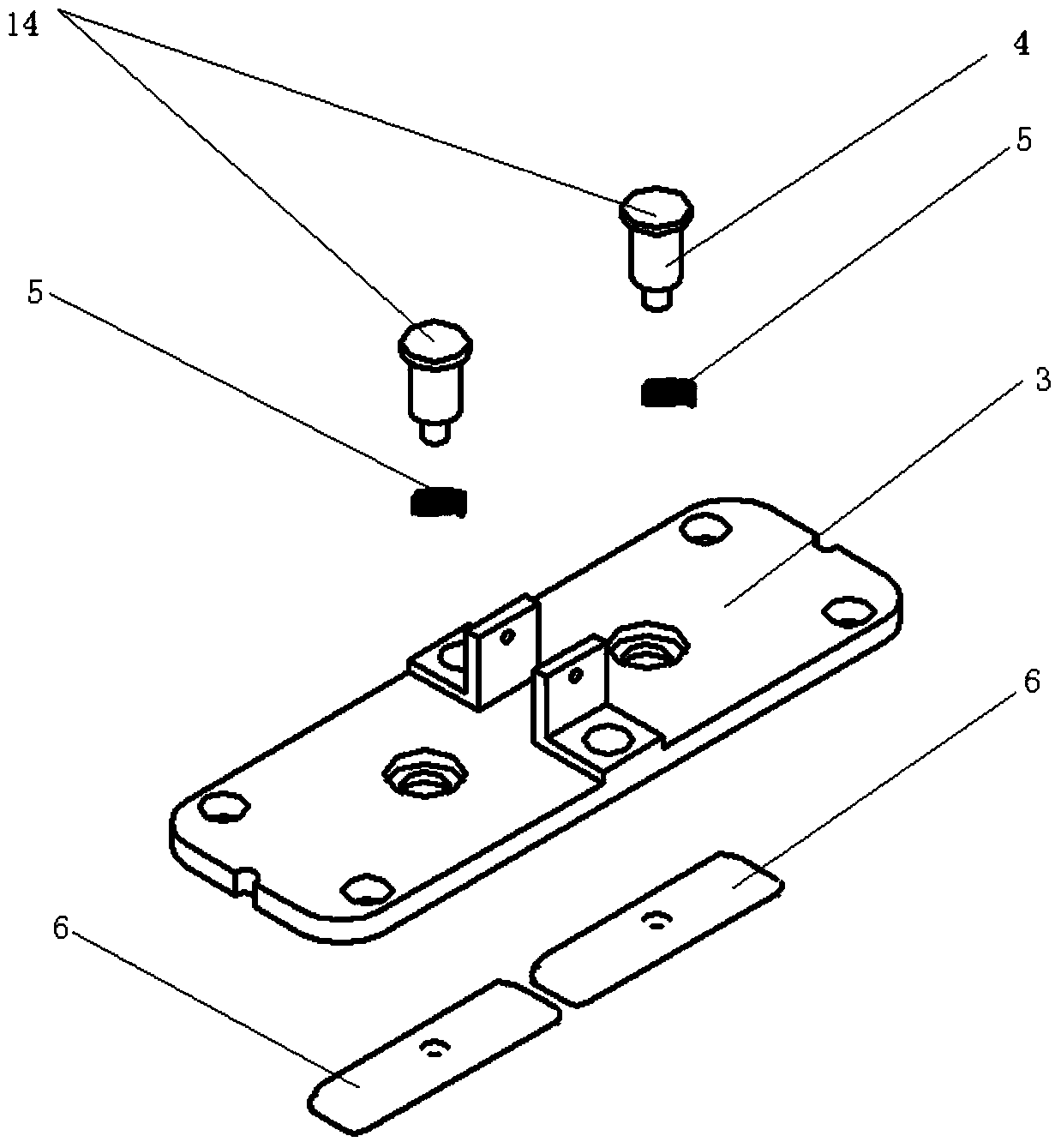

[0030] The guide system includes a base 1, two J-shaped driving pieces 2, a cover plate 3, two driving rods 4, two compression springs 5, two reeds 6, four supporting studs 7 and three joints 8, Such as Figure 3-5 As shown, the base 1 is a hollow cavity, and its bottom surface is provided with a through hole connected with the joint 8. One end of the joint 8 is placed in the cavity of the base 1, and the other end is placed outside the base 1. The cover plate 3 on the top of the base 1 has a through hole, and one end of the drive rod 4 is provided with a limit plate 14, and the clip spring 5 is set on the drive rod 4 and is limited by the limit plate 14 and the cover plate 3. Each drive rod 4 One end is put on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com