Fluid supply device and system and method for cleaning membrane using same

A fluid supply and cleaning system technology, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as the influence of membrane 4, and achieve the solution of membrane damage or defective products, reduce pressure deviation, The effect of preventing the film from sagging or bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

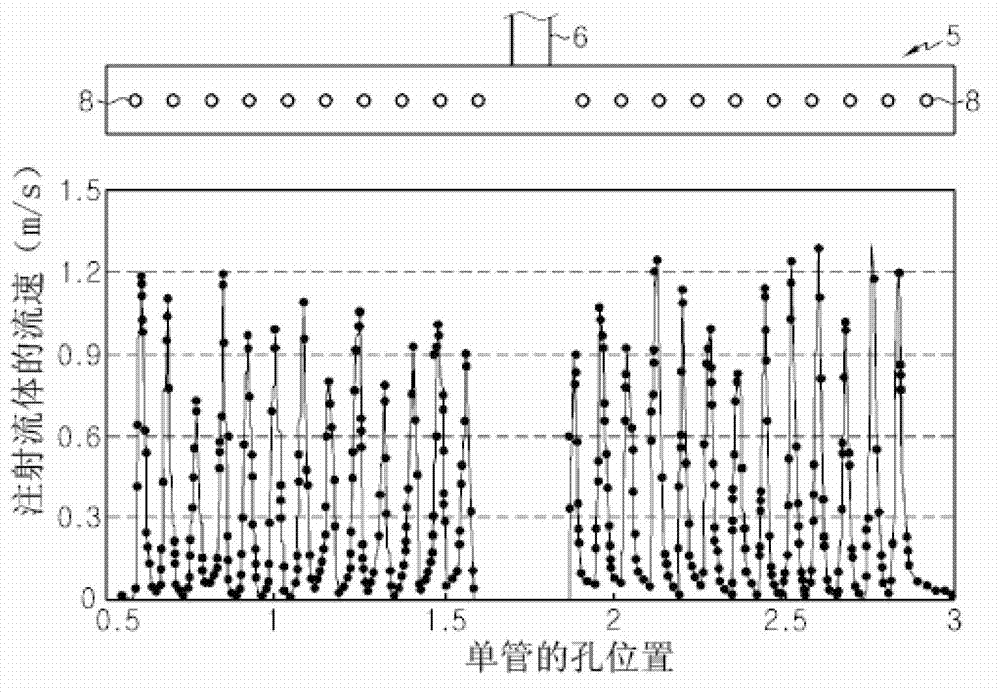

[0090] Figure 16 is a graph showing the flow rate test results of fluid released through each slit when the fluid supply devices according to the first, second and seventh embodiments are respectively applied to the membrane cleaning system according to the preferred embodiment of the present invention.

[0091] refer to Figure 16 , the double-tube type fluid supply device used in this experimental example has six slits (such as rear slits) continuously formed on one side of the outer tube along the length direction and six slits (such as front slits) continuously formed on the other side of the outer tube (such as front slit). Thus, in Figure 16 The Arabic numerals marked on the upper part close to the double pipe 300 represent the slit numbers (1-6) formed on the rear side and the slit numbers (7-12) formed on the front side respectively. Therefore, the measurements in this graph represent the flow rate of fluid injected through each slit.

[0092] according to Figu...

experiment example 1

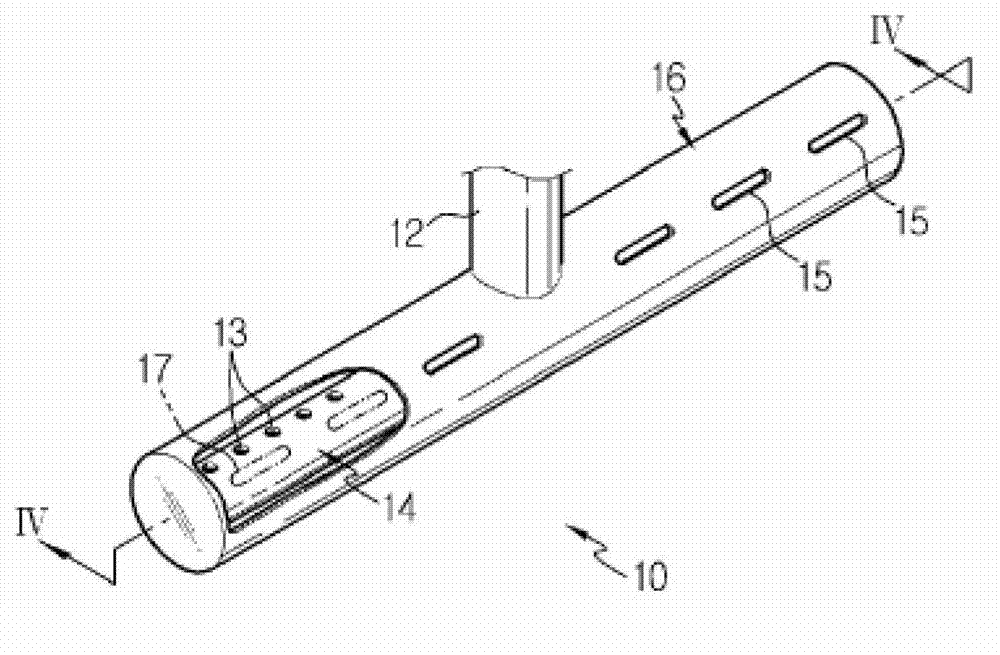

[0099]Table 2 shows the case of using the double tube type fluid supply device 10 according to the first embodiment of the present invention. In the double tube used in this Experimental Example 1, the inner tube 14 and the outer tube 16 each have a circular cross section. In other words, the inner tube 14 has a diameter of 100 mm, and each hole 13 has a diameter of 10 mm. Furthermore, the diameter of the outer tube 16 is 130 mm, and the length of the slits 15 and 17 is 240 mm.

[0100] Table 2

[0101]

experiment example 2

[0103] Table 3 shows the case of using the double tube type fluid supply device 20 according to the second embodiment of the present invention. In the double tube used in this Experimental Example 2, the inner tube 24 and the outer tube 26 each have an elliptical cross section. In other words, the inner tube 24 has a width of 200 mm and a height of 100 mm, and the hole 23 formed in the inner tube 24 has a diameter of 10 mm. Furthermore, the width of the outer tube 26 is 230 mm, the height is 130 mm, and the length of the slits 25 and 27 of the outer tube 26 is 240 mm.

[0104] table 3

[0105]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com