Improved preconditioning method for particulate filters

A particle filter and filter technology, which is applied in the direction of machines/engines, electronic control of exhaust treatment devices, diagnostic devices of exhaust treatment devices, etc., can solve problems such as reducing filtration capacity, and achieve the effect of improving filtration capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Various embodiments of conditioning methods and filter assemblies in accordance with the present disclosure are described in this detailed description. However, the method and filter assembly may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein; rather, these embodiments are provided for thoroughness and completeness, and to extend the scope of the present disclosure fully conveyed to those skilled in the art. In some instances, well-known structures and devices are shown in block diagram form in order to avoid obscuring the novelty of the exemplary embodiments presented herein. Throughout the text, the same reference numbers refer to the same elements.

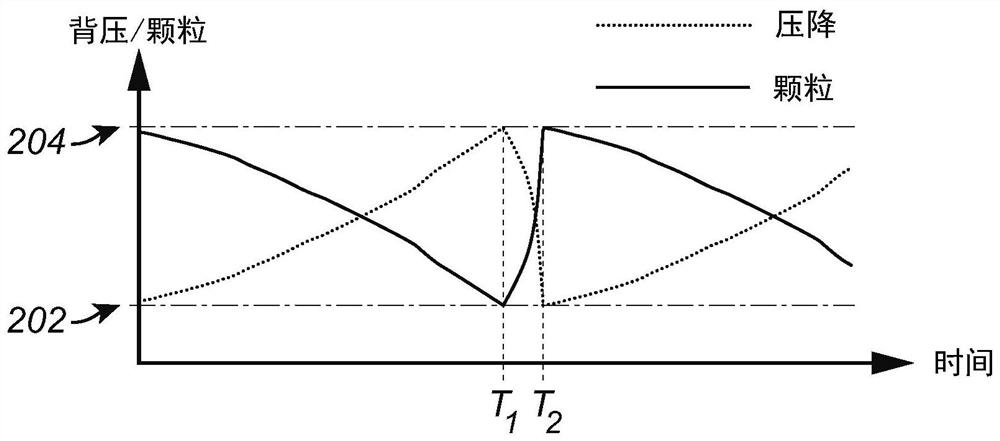

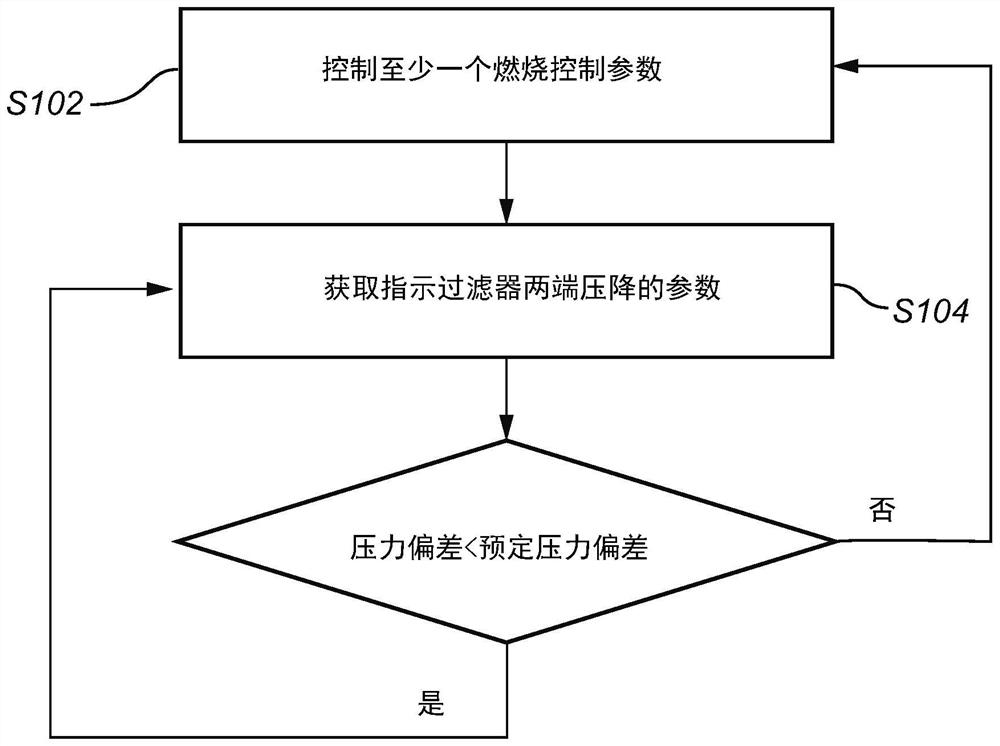

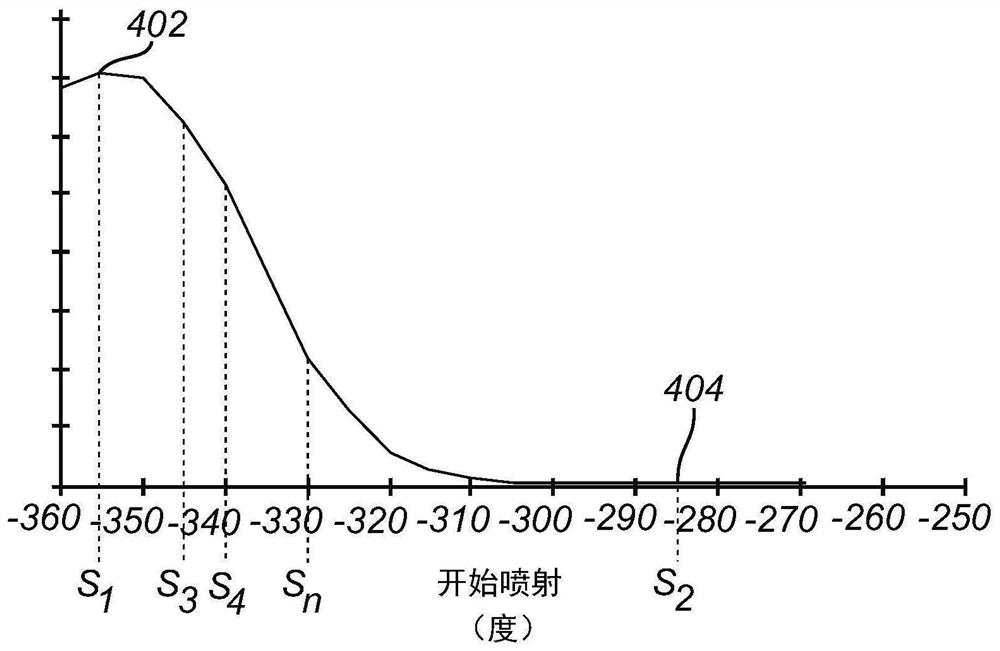

[0023] Generally, filter efficiency depends on the amount of soot loading in the filter. High levels of soot in the filter (ie, particles captured by the filter) result in higher filtration efficiency (ie, fewer particulates in the exhaust filtered airflow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com