A kind of heat pump-refrigeration unit nitrogen charging and pressure maintaining leak detection equipment and control method thereof

A technology of refrigeration units and heat pumps, which is applied in the field of quality inspection and control devices of devices or systems, and compression equipment, which can solve difficult problems such as nitrogen recovery and utilization functions, so as to save production space, reduce equipment costs and operating costs, and pressure deviation small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to better understand the above technical solutions of the present invention, a further detailed description will be given below in conjunction with the drawings and embodiments.

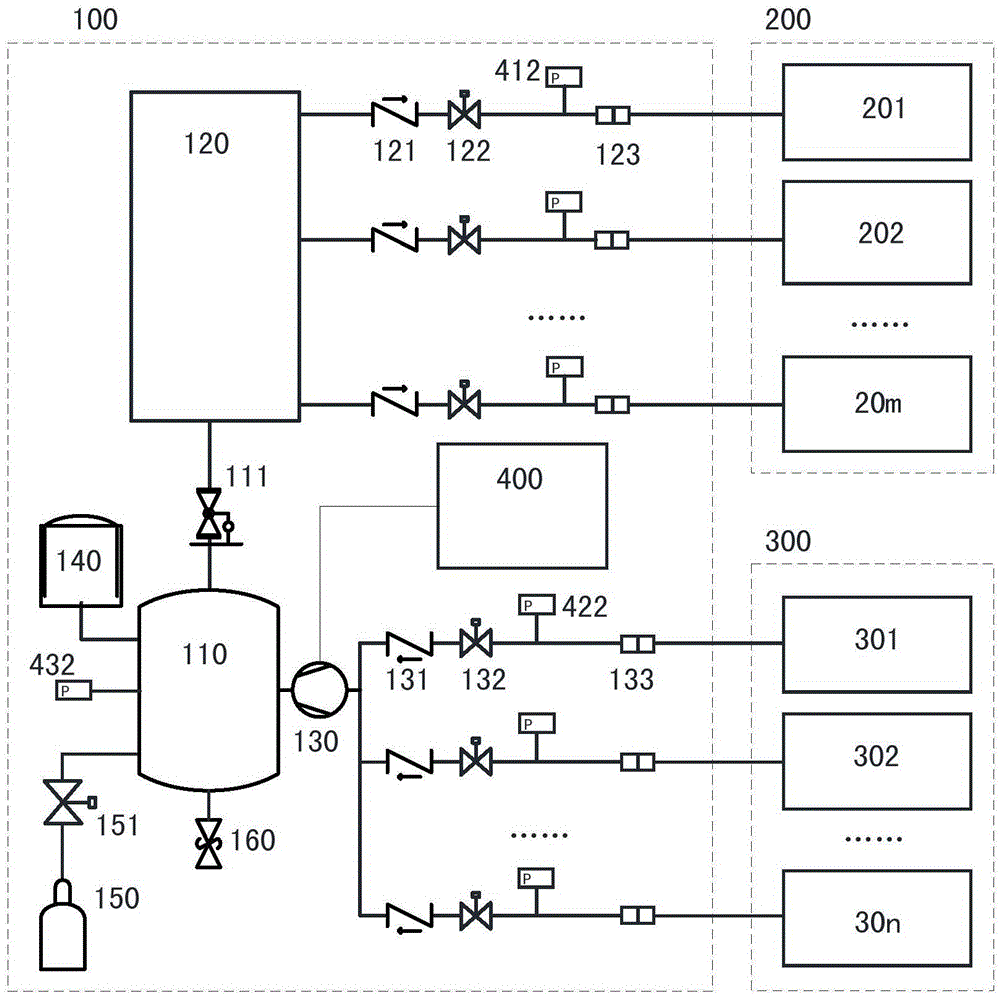

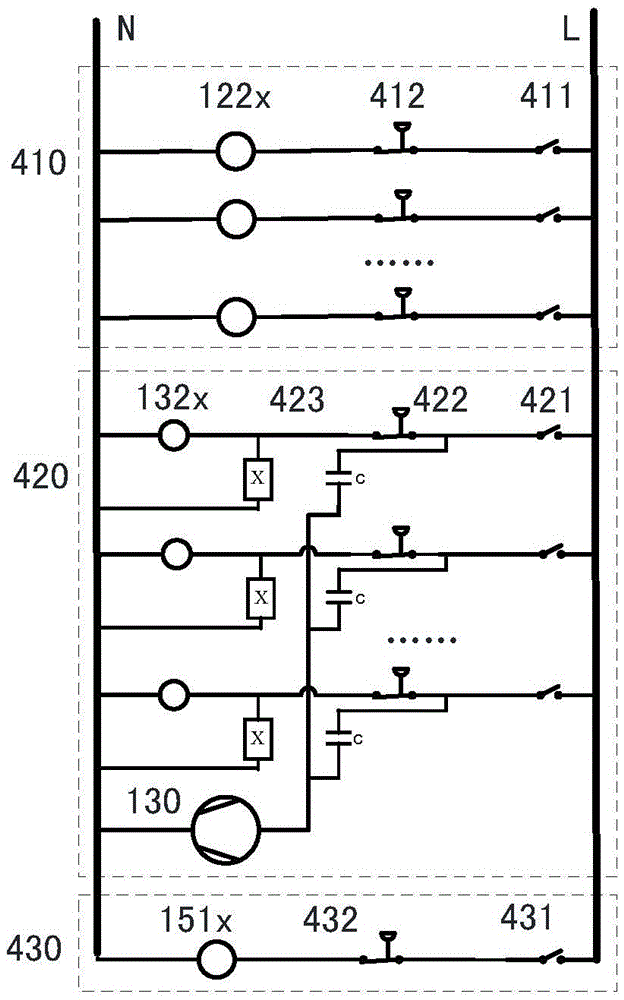

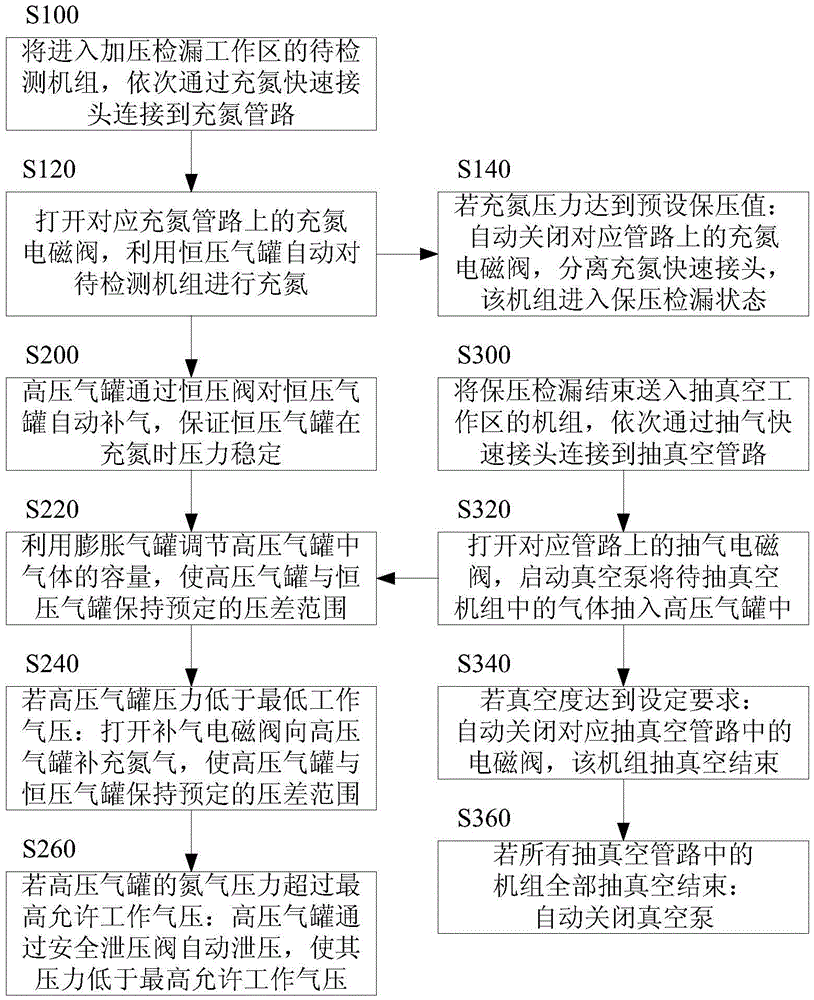

[0044] The nitrogen-filling and pressure-maintaining leak detection equipment for heat pump refrigeration units of the present invention is used for nitrogen-filling and pressure-maintaining leak detection and nitrogen recovery in the heat pump or refrigeration unit production line, according to figure 1 In the illustrated embodiment, the heat pump or refrigerating unit production line includes a pressurized leak detection work area 200 for accommodating m sets of units to be tested and a vacuum work area 300 for accommodating n sets of units to be evacuated. The pressure leak detection equipment 100 includes a high pressure gas tank 110, a constant pressure gas tank 120, a vacuum pump 130, an expansion gas tank 140 and a nitrogen cylinder 150, m lines of nitrogen filling pipelines con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com