Fully automatic pointer pressing system and method based on pressure feedback

A fully automatic, pointer technology, used in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as large pointer height deviation and large pressure deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

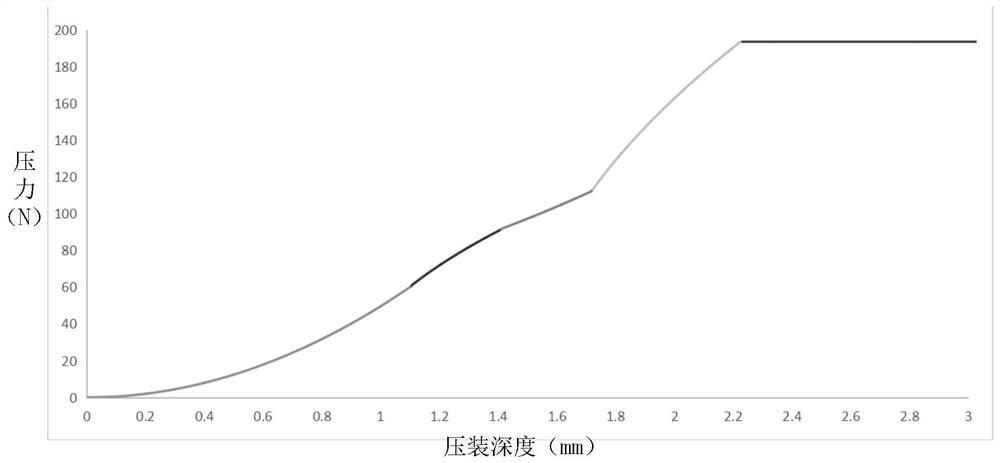

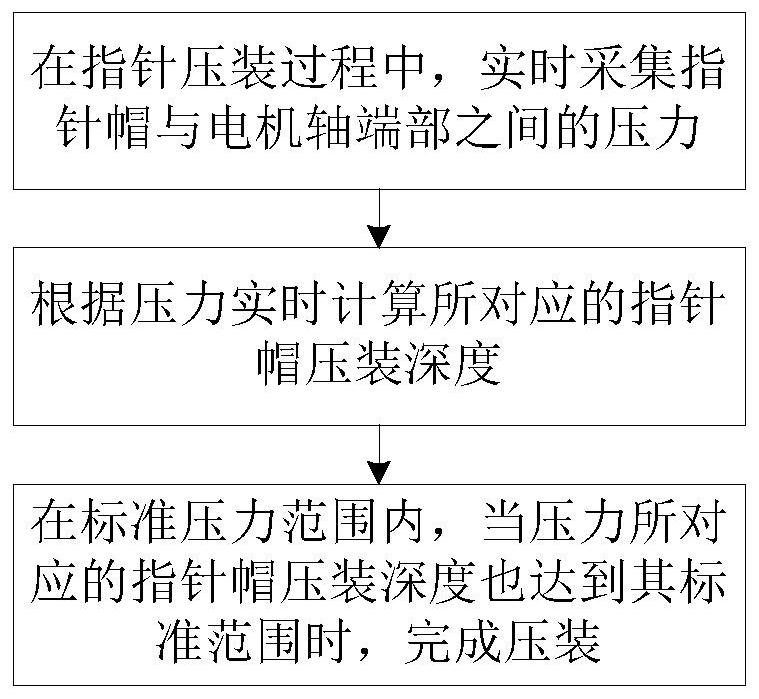

[0036] Specific implementation mode one: refer to figure 1 and 2 Specifically explaining this embodiment, the pressure feedback-based fully automatic pointer pressing method described in this embodiment includes the following steps:

[0037] Collect the information of the previous station and judge whether the information of the previous station is qualified. When the information of the previous station is qualified, start to execute step 1, otherwise stop the pressing.

[0038] Step 1: During the pressing process of the pointer, the pressure between the pointer cap and the end of the motor shaft is collected in real time,

[0039] After collecting the pressure between the pointer cap and the end of the motor shaft, delay 50ms and then perform step 2.

[0040] Step 2: Calculate the corresponding pressing depth of the pointer cap in real time according to the pressure,

[0041] Step 3: Within the standard pressure range, when the press-fit depth of the pointer cap correspond...

specific Embodiment approach 2

[0049] Embodiment 2: The pressure feedback-based fully automatic pointer pressing system described in this embodiment includes the following modules:

[0050] Initialize the module:

[0051] Collect the information of the previous station, and judge whether the information of the previous station is qualified,

[0052] When the information of the last station is qualified, start the pressure acquisition module,

[0053] When the information of the previous station is unqualified, the driver will alarm.

[0054] Pressure acquisition module: During the pointer press-fitting process, the pressure between the pointer cap and the end of the motor shaft is collected in real time,

[0055] Delay module: After collecting the pressure between the pointer cap and the end of the motor shaft, delay 50ms before starting the pressing depth acquisition module.

[0056] Pressing depth acquisition module: Calculate the corresponding pointer cap pressing depth in real time according to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com