Polishing pad for a polishing system

A polishing pad and polishing liquid technology, applied in the field of polishing pads, can solve the problems of slippage in the polishing process, high polishing rate, large amount of polishing liquid, etc., and achieve the effect of uniform and wide process range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

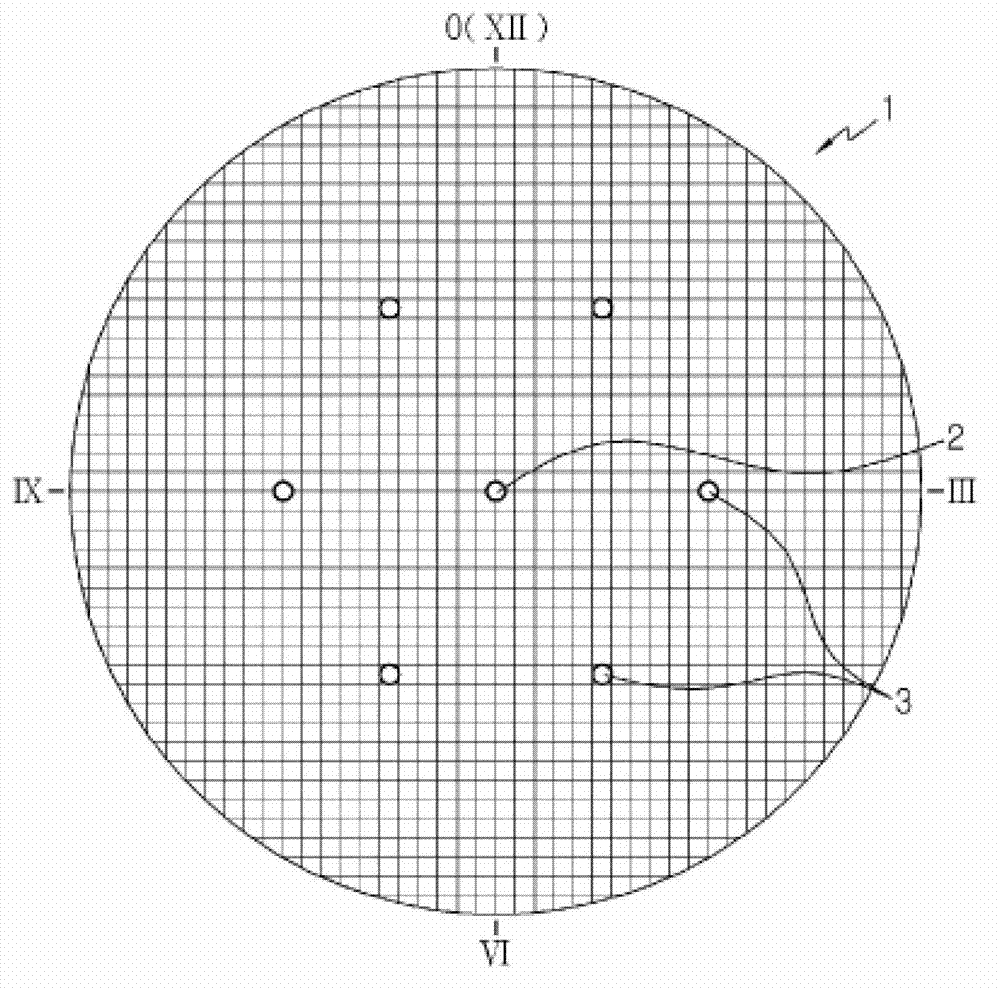

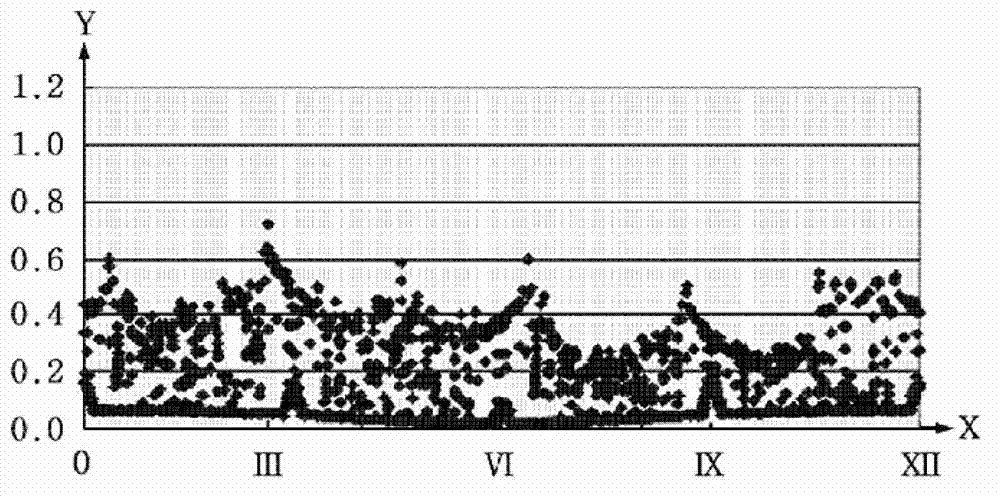

Image

Examples

Embodiment Construction

[0042] The words used in the following detailed description are for the sake of convenience and should not be used to limit the present disclosure. Words such as "left", "right", "top", and "bottom" denote different directions referred to in the drawings. Words such as "inwardly" and "outwardly" denote directions towards and away from, respectively, the geometric center of the respective designed instrument. Words such as "front", "rear", "above", "below" and their related words and phrases indicate the position and orientation of references in the drawings and they are not intended to limit the present disclosure. These words include those listed above, their derivatives, and their synonyms.

[0043] Exemplary embodiments will be described with reference to the drawings.

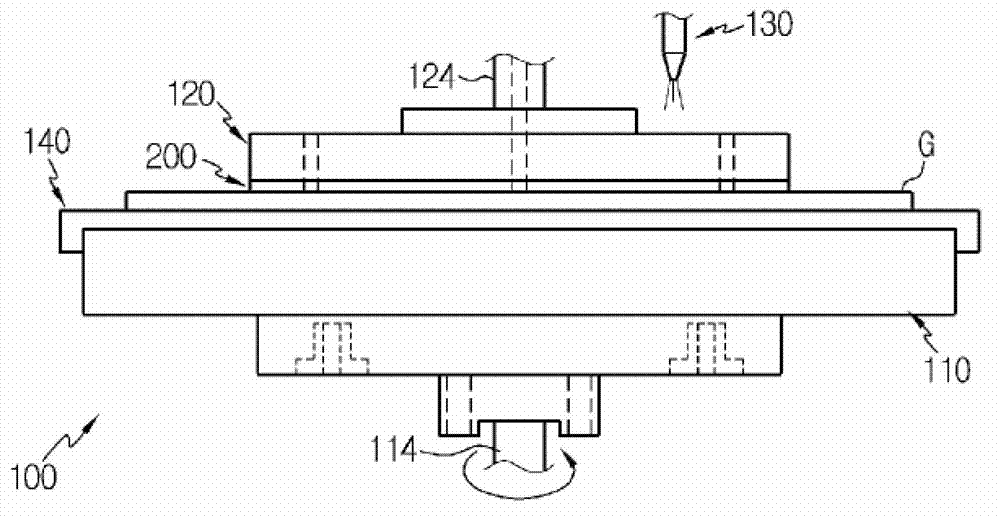

[0044] image 3 is a schematic diagram illustrating a glass plate polishing system in which a polishing pad according to a preferred embodiment of the present disclosure may be installed.

[0045] refer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com