Grain-oriented electrical steel sheet and manufacturing method thereof

A technology of electromagnetic steel sheet and manufacturing method, which is applied in the manufacture of inductors/transformers/magnets, manufacturing tools, circuits, etc., can solve the problems such as the balance of manufacturing cost, and achieve the effect of excellent iron loss characteristics and low iron loss characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

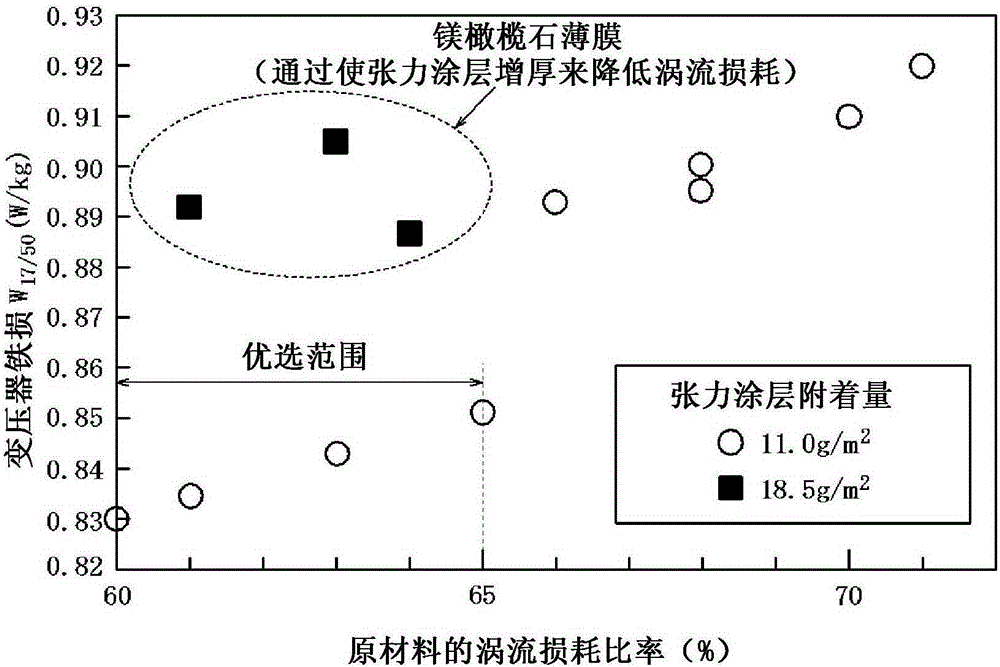

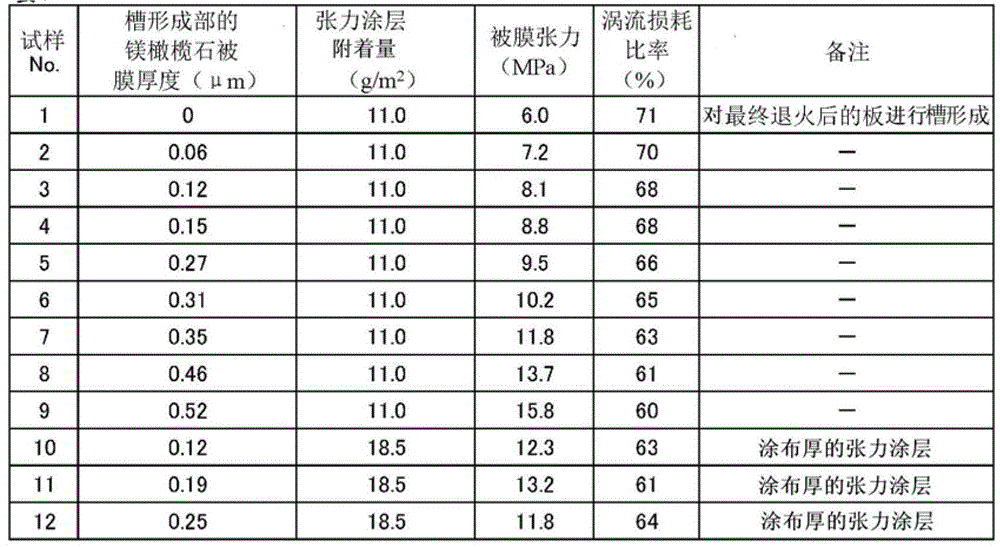

Embodiment 1

[0108] Steel slabs having the composition shown in Table 2 were produced by continuous casting, heated to 1400° C., and then hot-rolled to form hot-rolled sheets with a thickness of 2.2 mm. Then, the hot-rolled sheets were annealed at 1020° C. for 180 seconds. Next, it is made into an intermediate plate thickness of 0.55 mm by cold rolling, and in the atmosphere oxidation degree P (H 2 O) / P(H 2 )=0.25, time: 90 seconds to implement intermediate annealing. Then, after removing the secondary scale on the surface by hydrochloric acid pickling, cold rolling was performed again to obtain a cold-rolled sheet having a thickness of 0.23 mm.

[0109] [Table 2]

[0110]

[0111] The balance is Fe and unavoidable impurities

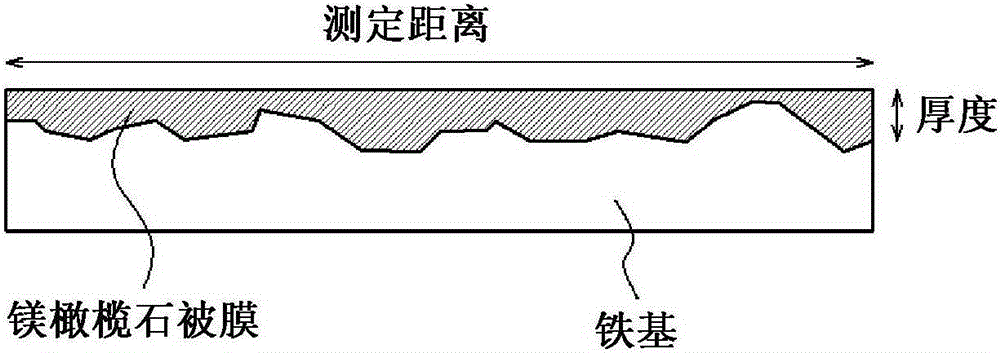

[0112] Then, a resist was applied by gravure offset printing, followed by electrolytic etching and resist stripping in an alkali solution, and a width of 150 μm was formed at an inclination angle of 10° with respect to the direction perpendicular to the rollin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com