Grain oriented electrical steel sheet and method for manufacturing the same

A technology of electromagnetic steel sheet and manufacturing method, applied in the direction of inductance/transformer/magnet manufacturing, manufacturing tools, circuits, etc., can solve problems such as the existence of boundaries, and achieve the effect of excellent low iron loss characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

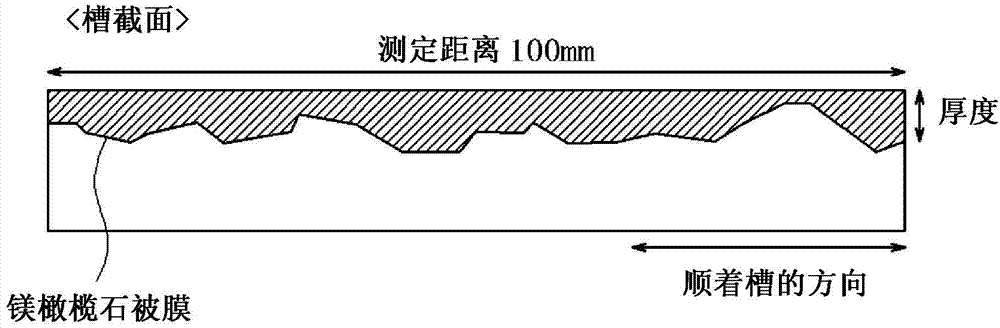

[0120] Steel slabs having the composition shown in Table 1 were produced by continuous casting, heated to 1400° C., hot-rolled into hot-rolled sheets with a thickness of 2.2 mm, and then annealed at 1020° C. for 180 seconds. Next, it is made into an intermediate plate thickness of 0.55mm by cold rolling, and the oxidation degree PH 2 O / PH 2 =0.25, temperature: 1050° C., and time: 90 seconds for intermediate annealing. Then, after removing the secondary scale on the surface by hydrochloric acid pickling, cold rolling was performed again to obtain a cold-rolled sheet having a thickness of 0.23 mm.

[0121] [Table 1]

[0122]

[0123] The balance is Fe and unavoidable impurities

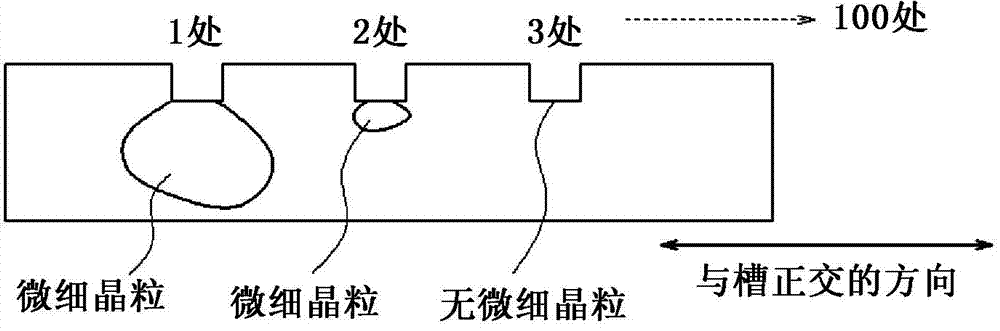

[0124] Then, a resist was applied by gravure offset printing, followed by electrolytic etching and resist stripping in an alkali solution, and a width of 150 μm was formed at an inclination angle of 10° with respect to the direction perpendicular to the rolling direction at intervals of 3 mm. Lin...

Embodiment 2

[0131] About the steel slab of the composition shown in Table 1, it carried out to cold rolling using the same procedure and conditions as Example 1. Then, the surface of the steel sheet was locally pressed with a protruding roll, and linear grooves with a width of 150 μm and a depth of 20 μm were formed at intervals of 3 mm at an inclination angle of 10° relative to the direction perpendicular to the rolling direction. Next, implement the oxidation degree PH 2 O / PH 2 =0.50, After decarburization annealing held at a soaking temperature of 840° C. for 300 seconds, an annealing separator mainly composed of MgO was applied. At this time, as shown in Table 3, the application amount of the annealing separator and the winding tension after the application of the annealing separator were changed. Then, at N 2 :H 2 The final annealing for the purpose of secondary recrystallization and purification was carried out under the conditions of 1230° C. and 100 hours in a mixed atmosphere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com