Battery module and method for joining unit terminals of battery cells together

A technology for battery cells and battery modules, which is applied to small-sized batteries/battery packs, electrical components, battery boxes/jackets, etc., and can solve the problems of occupying manufacturing time and large manufacturing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

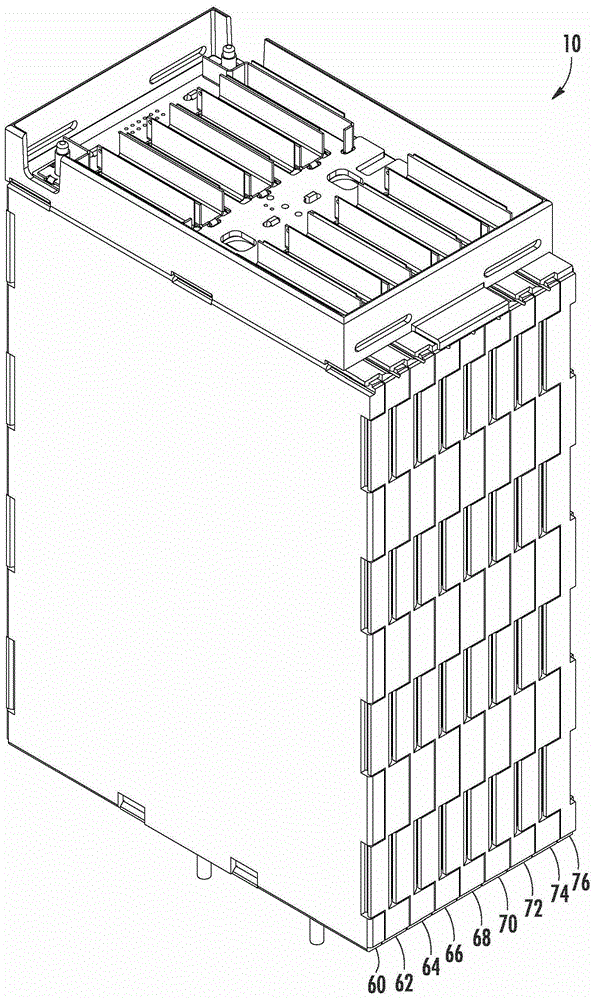

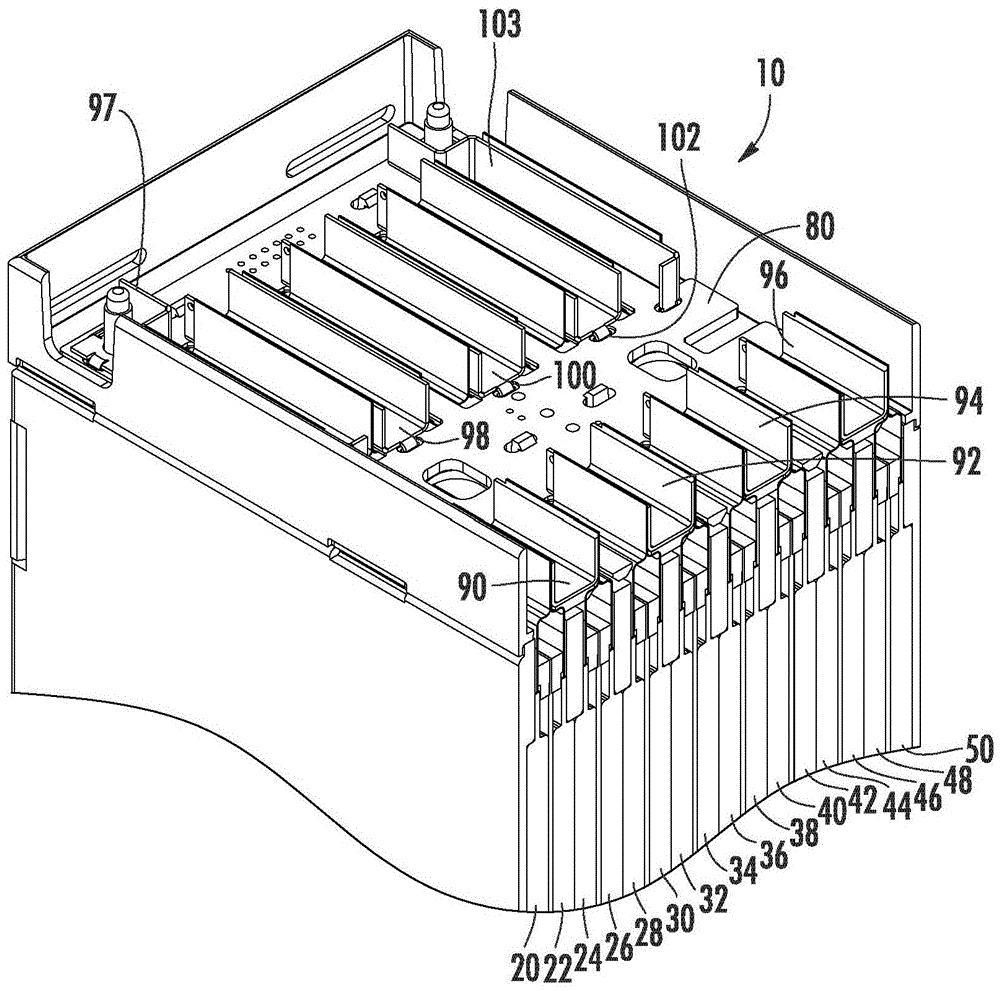

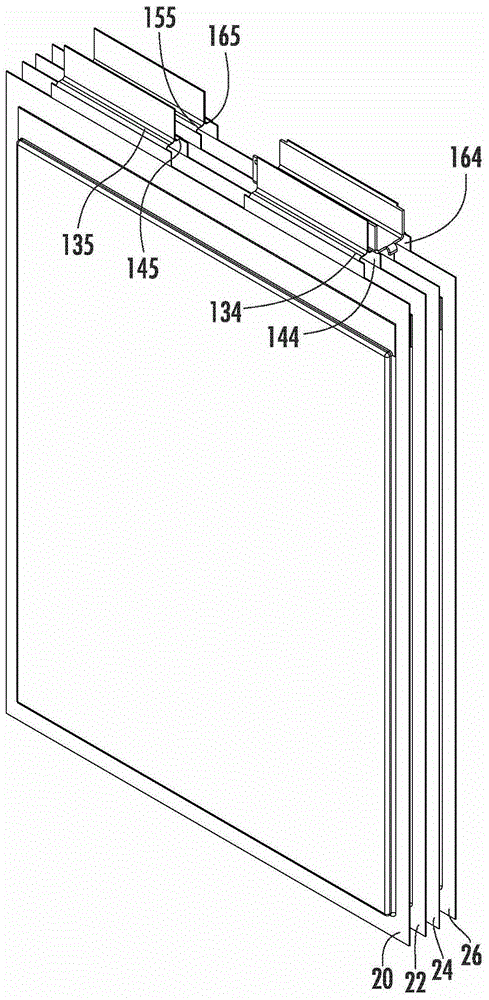

[0022] refer to figure 1 , illustrates a schematic diagram of a battery module 10 configured to provide power to a battery electric vehicle or a hybrid vehicle according to an exemplary embodiment. refer to figure 1 , 2 and 4, the battery module 10 includes battery cells 20, 22, 24, 26, 28, 30, 32, 34, 36, 38, 40, 42, 44, 46, 47, 48, 50; frame members 60, 62, 64 , 66, 68, 70, 72, 74, 76; circuit board 80; interconnect members 90, 92, 94, 96, 97, 98, 100, 102, 103; and include exothermic reactive layers 110, 112, 114, 116 exothermic reaction layer. One advantage of the battery module 10 is that the module 10 utilizes an exothermic reactive layer that can be ignited with a laser beam during the manufacture of the module 10 to very quickly bond the cell terminals of the battery cells together and Cell terminals are bonded to associated interconnection members. An exothermic reactive layer refers to a layer that generates heat after being ignited.

[0023] refer to figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com