Lifting chair

A seat and seat surface technology, applied in the field of lift seats, can solve the problem that the lift seats cannot be disassembled, packaged and transported, and achieve the effects of simple and stable structure, convenient installation, convenient packaging and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

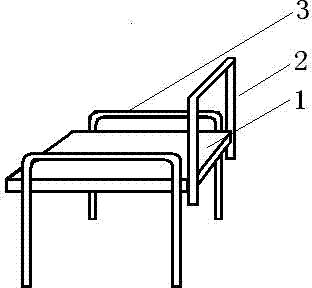

[0011] Such as figure 1 Shown: Use wood or plastic for the seat surface.

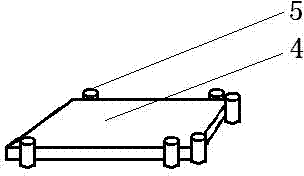

[0012] Such as image 3 Shown: Metal materials are used to weld the seat base.

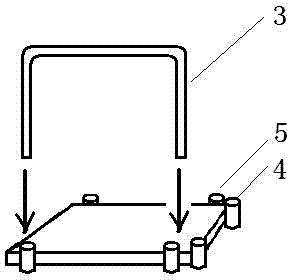

[0013] Such as image 3 Shown: use metal material welding or hot bending, cold bending to make chair legs and backrest.

[0014] Such as Figure 4 Shown: Drill holes for the seat base fixing pipe, chair legs and backrest.

[0015] Installation before sales: the chair surface and the chair surface base are fixed together, and the chair legs and backrest are not fixed on the chair surface base, and are directly packaged.

[0016] Installation during use: insert the chair legs and backrest into the fixing tube on the seat base, adjust the height and fix them, and the installation is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com