Steel belt torsion device

A steel strip and steel strip technology, applied in the field of strip steel continuous production line equipment, can solve the problems that the steel strip cannot change the rotation angle, the vertical roller cannot clamp the steel strip, and cannot reverse the reverse rotation, etc., achieving low maintenance cost and novel structure , The effect of clamping the steel strip firmly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

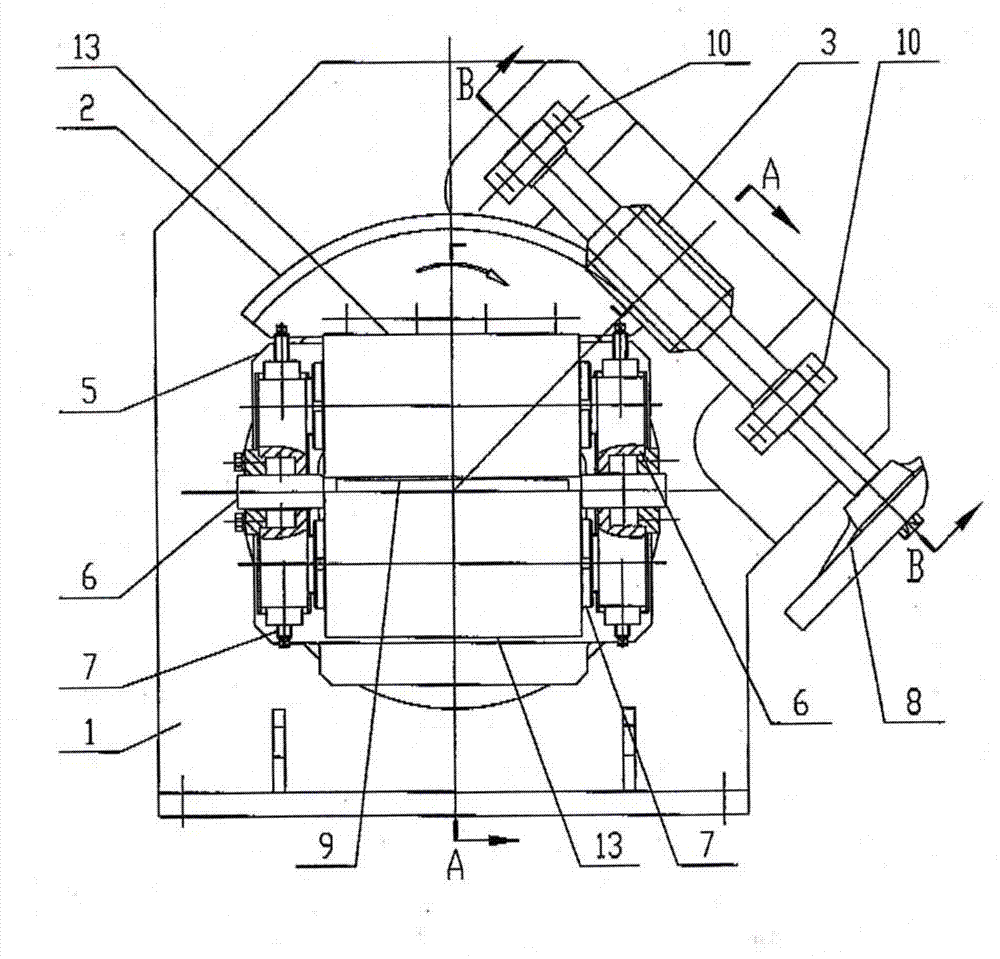

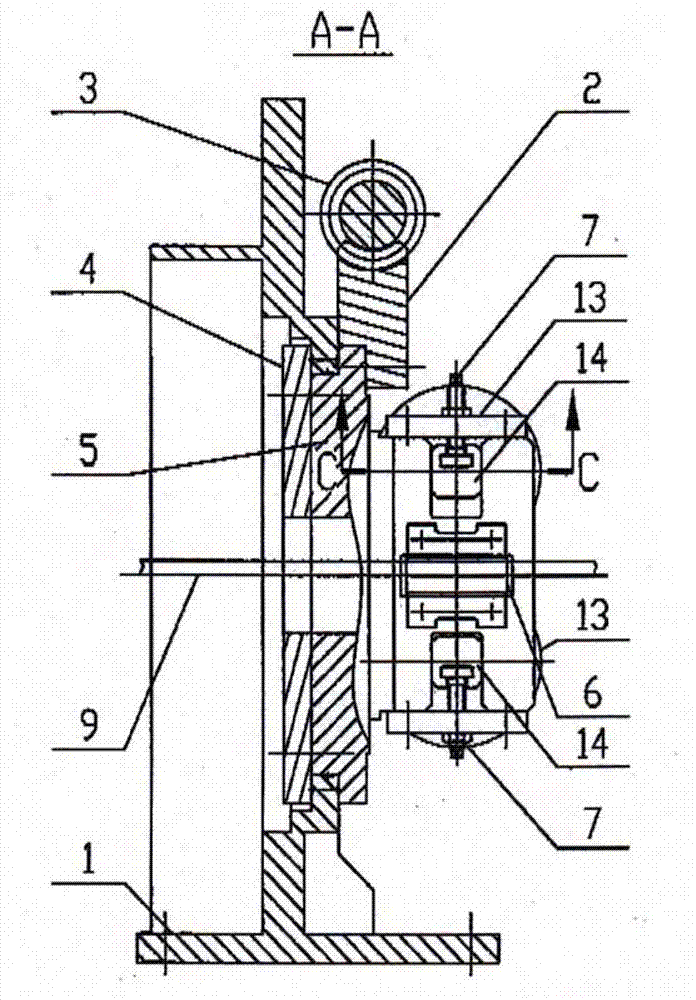

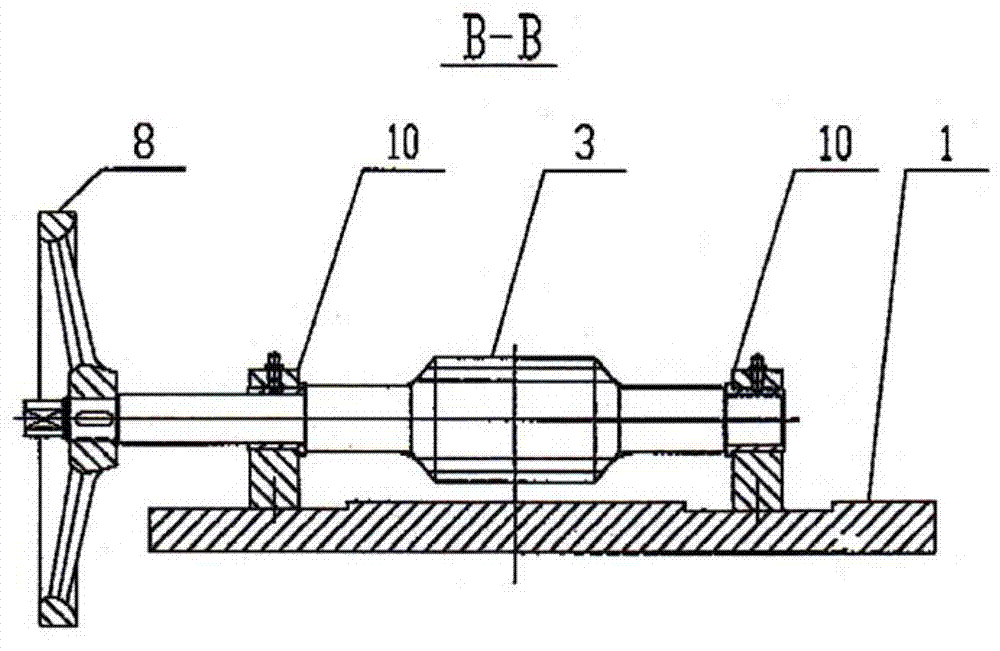

[0022] figure 1 , 2 Shown in , 3, 4 is the specific embodiment of the present invention, and it is the steel strip torsion device installed on the entrance section of the narrow and thick strip steel continuous production line of coiling; Described steel strip torsion device comprises support 1, flat roller, The vertical roller and the rotating bracket 5 are characterized in that: the fan-shaped worm wheel 2, the worm 3, the pressing plate 4, the rotating bracket 5, the vertical roller 6, the adjusting screw 7, the hand wheel 8, the worm bracket, and the flat roller are installed on the support 1. , and the rotating bracket of the manual worm gear and worm composed of the flat roller shaft, the support 1 has a shaft hole, and the rotating bracket 5 is connected to the support 1 through the shaft hole, and is pressed by the pressure plate 4 to realize its rotation. The bracket 1 rotates along the shaft hole of the support; two flat rollers 13 are symmetrically installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com