Ink-jet printing method and ink-jet printer

An inkjet printer and inkjet printing technology, applied in the direction of copying/marking methods, printing, etc., can solve the problems of thermal transfer equipment such as complex structure, complicated operation process, and poor applicability, so as to save the transfer process and control Simple and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The inkjet printing method and inkjet printer of the present invention will be described in detail below with reference to the accompanying drawings.

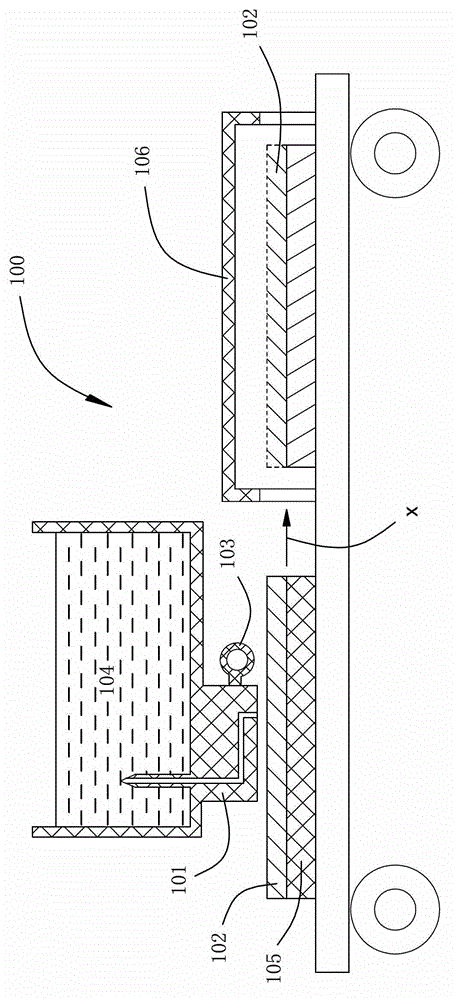

[0020] see figure 1 , shows a schematic structural view of the inkjet printer of the present invention.

[0021] The main configuration of this inkjet printer 100 includes an inkjet head 101 . The inkjet head 101 is used to spray the thermal transfer ink 104 on the substrate 102 so as to form a pattern required by the user on the surface of the substrate 102 . The substrate 102 is a semi-finished product used to carry the pattern required by the user, for example, a sheet for making a mobile phone case that still needs to be processed by a final molding process.

[0022] In the vicinity of the inkjet head 101, a heating mechanism such as a resistance heating tube 103 is provided. For the area of the substrate 102 that is just covered by the thermal transfer ink 104 after spraying, the heat generated by the resistanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com