Metal-phobic material and application thereof

A metal material and metal technology, which is applied in the field of metal-phobic materials and its applications, can solve the problems of high surface tension of liquid metal, high production cost, and limited application, so as to improve production efficiency, reduce production cost, and expand the scope of application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0071]The composition of thin metal materials is as follows:

[0072] Material type Specific selection Dosage proportion Resin film former Vinyl resin 10g24.4% Solvent Ethylene glycol butyl ether 20g48.8% Metal sparse functional powder Mercerized Mica 10g24.4% Dispersant BYK110 1g2.4% total 41g100%

[0073]The preset temperature of the aforementioned metallic material is 120 degrees Celsius.

example 2

[0075]The composition of thin metal materials is as follows:

[0076] Material type Specific selection Dosage proportion Resin film former polyester resin 12g24.5% Solvent Butyl acetate 20g40.8% Metal sparse functional powder Montmorillonite powder 15g30.6% Dispersant BYK110 2g4.1% total 49g100%

[0077]The preset temperature of the aforementioned metallic material is 140 degrees Celsius.

example 3

[0079]The composition of thin metal materials is as follows:

[0080]

[0081]

[0082]The preset temperature of the aforementioned metallic material is 146 degrees Celsius.

[0083]In addition, the present invention provides the application of any one of the above-mentioned metal-phobic materials. The metal-phobic material is used in electronic devices with liquid metal circuits, or in liquid metal printing, or in structures that are isolated from liquid metal.

[0084]The above-mentioned structure of alienating liquid metal can be containers, platforms, tools, etc. that need to be contacted during production, production, storage, transportation, and use of liquid metal, such as ink cartridges, ink distribution tables, ink distribution rollers, doctor blades, pipelines, and Structures such as metal substrates, and metal sparse materials are present in the above structures in the form of coatings.

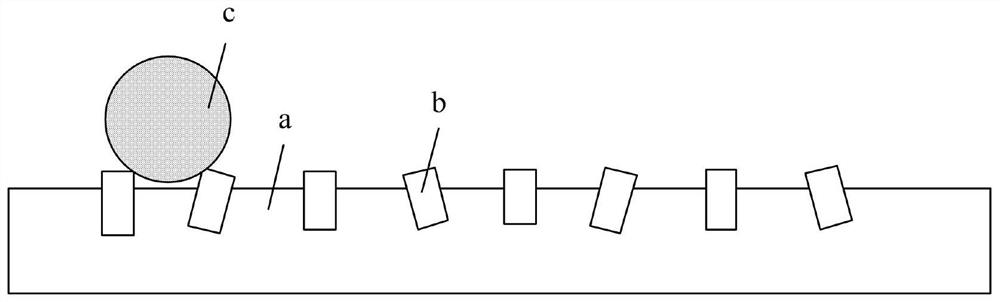

[0085]When the metal-phobic material is applied to liquid metal printing, optionally, such asimage 3 A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com