Hidden type side outer plate

A side wall outer panel, hidden technology, applied in the superstructure, superstructure sub-assembly, transportation and packaging, etc., can solve problems such as affecting the appearance of the vehicle, poor dimensional accuracy, and increasing the cost of the vehicle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

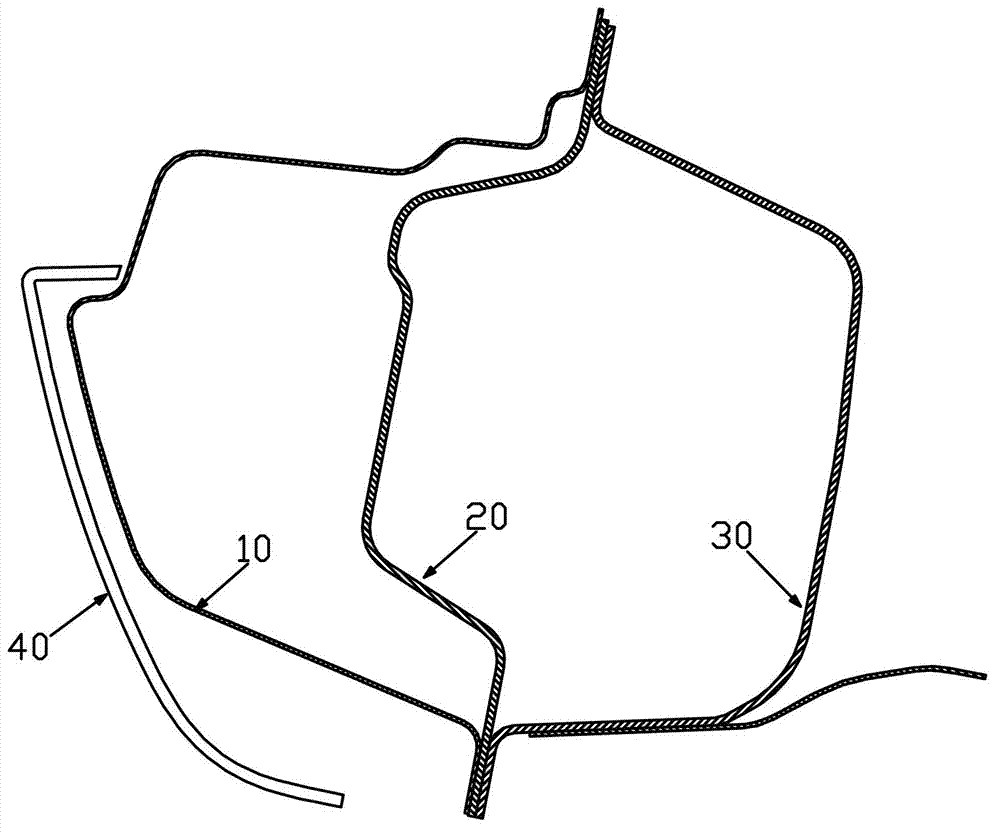

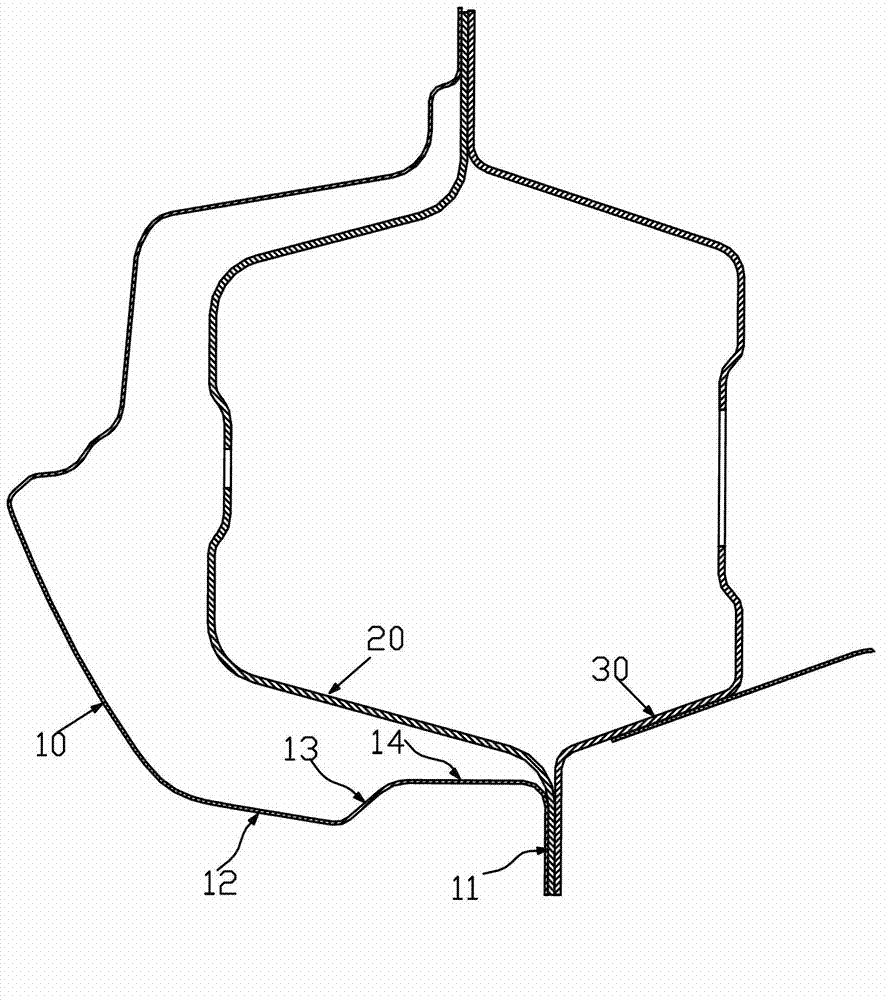

[0008] Such as figure 1 , a hidden side wall panel, the bottom of the side wall panel 10 is provided with a flange 11 facing the bottom of the vehicle, and the panel body between the threshold section 12 of the side wall panel 10 and the flange 11 faces the vehicle The inner direction is raised, in other words, the side wall outer panel 10 behind the threshold section 12 is first raised to the inner side of the car and then flanged 11 to the bottom of the car. The raised height is guaranteed to be viewed from a distance of seven or eight meters This structure is equivalent to lifting the flange 11 upwards for a certain distance, using the structure of the side wall outer panel 10 to cover the welding point, without adding side skirt guards, and solving the problem while ensuring the length of the flange 11 Aesthetic issues, cost savings, and reduced body weight.

[0009] The bottom end of the door sill section 12 of the side wall outer panel 10 is bent obliquely toward the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com