A Method of Improving Laser Cutting Quality of Accelerometer Pendulum

An accelerometer and sheet laser technology, applied in glass cutting devices, glass manufacturing equipment, glass production, etc., can solve the problems of reducing the temperature gradient at the slit, reducing the energy of the laser beam, and not being able to solve the slit, so as to reduce the cutting Seam taper, improve the size consistency of double-sided graphics, and improve the effect of processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

[0028] The present invention as Figure 4 shown in the following steps:

[0029] 1. Make cutting auxiliary device

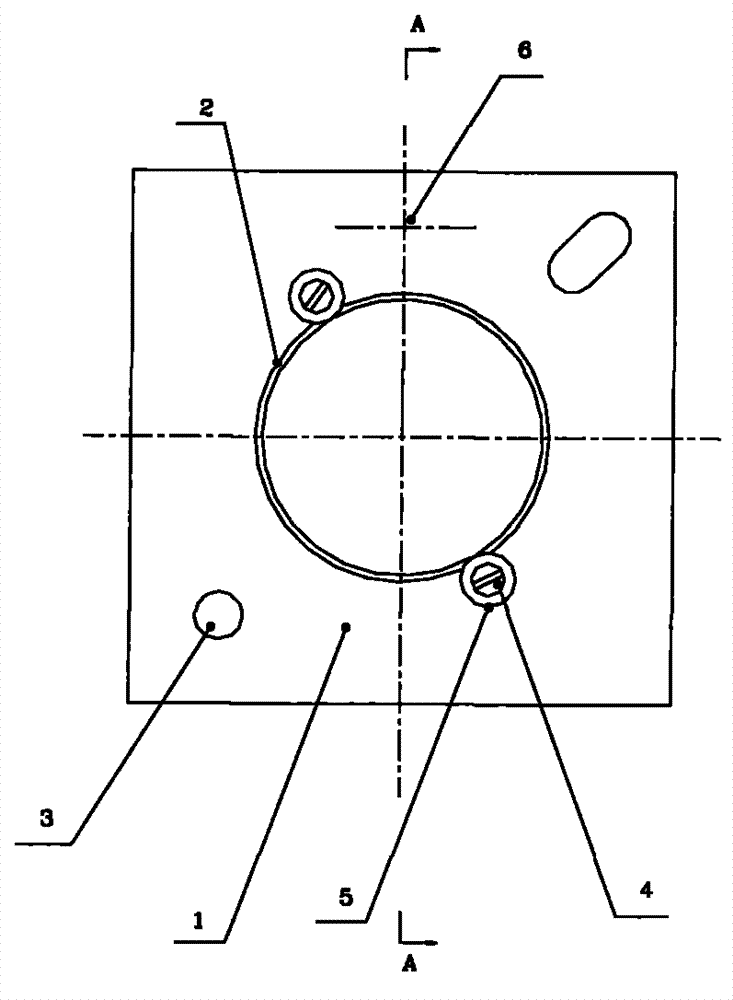

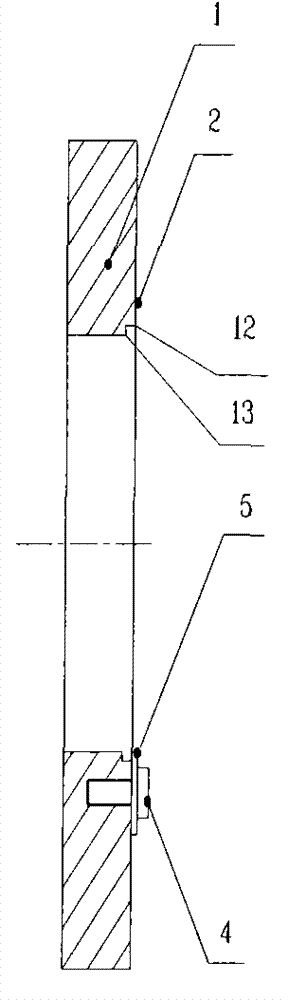

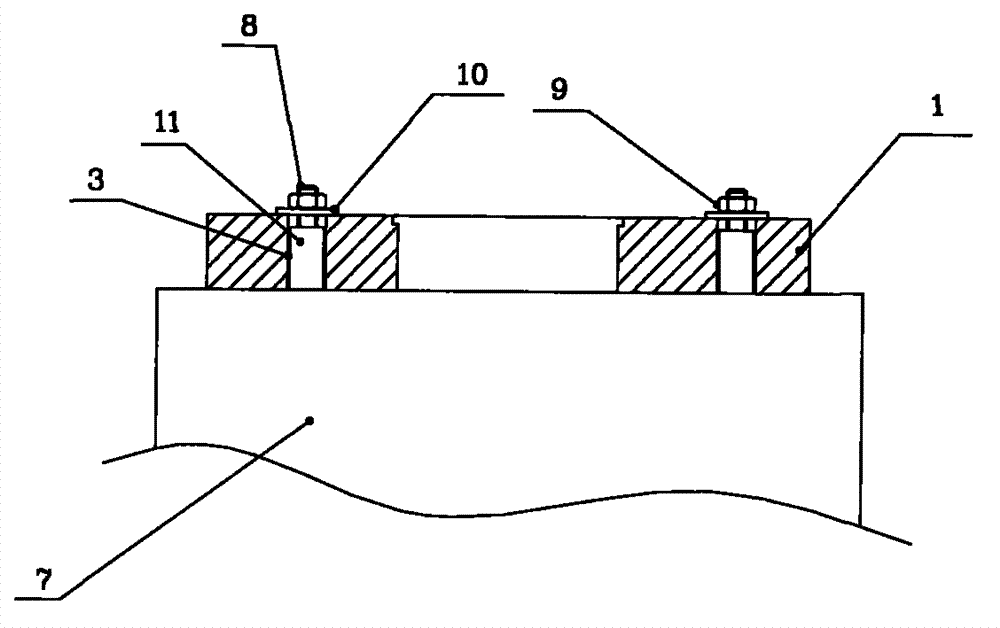

[0030] cutting aids such as Figure 1~2 As shown, it includes precision connection datums, support parts and workpiece fixing structures to perform the functions of cutting positioning, workpiece support and workpiece fixing respectively.

[0031] The precision connection reference includes a positioning hole 3 and a reference mark line 6 . The number of positioning holes 3 is two or other numbers that facilitate the positioning of the auxiliary device, and its shape is a round hole or a waist-shaped hole, or a combination of the two. The positioning holes 3 are through holes, which are convenient for positioning pins to pass through; The marking line 6 is a straight line or two mutually perpendicular straight lines.

[0032] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com