Pouring foam car

A foaming car and pouring head technology, which is applied in the directions of roads, tracks, ballast layers, etc., can solve the problems of unfavorable large-scale application of railway track ballast beds, inability to efficiently prepare polyurethane ballast ballast beds, etc., saving manpower and time, Efficient pouring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In the following, the embodiment of the pouring and foaming vehicle of the present invention will be described by taking polyurethane pouring for ballast bed as an example. However, those skilled in the art should understand that the pouring and foaming vehicle according to the present invention can be applied to a variety of occasions where the pouring point needs to be poured, and these descriptions are only used to explain the principle of the present invention by way of example, and are not intended to explain the principles of the present invention. Limitations on the protection scope and application scope of the invention.

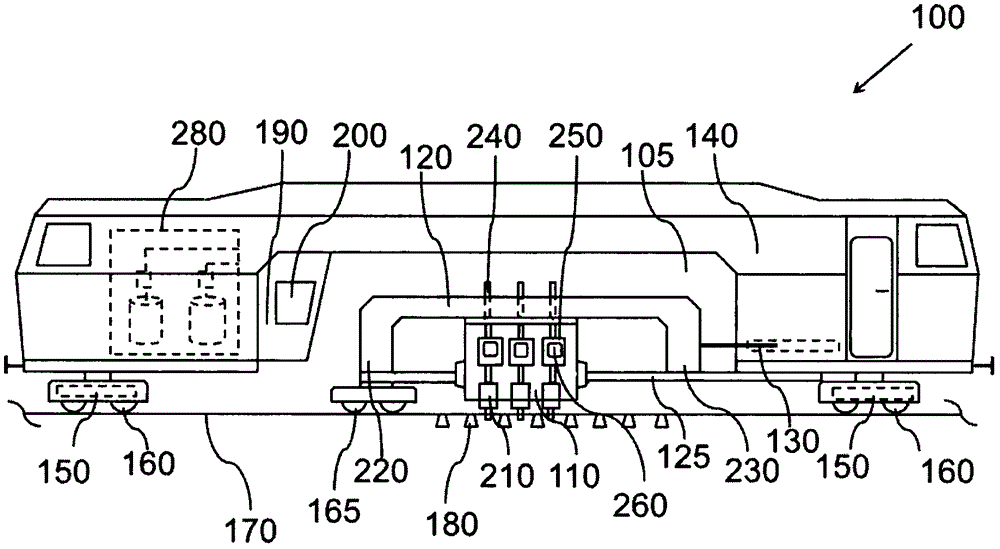

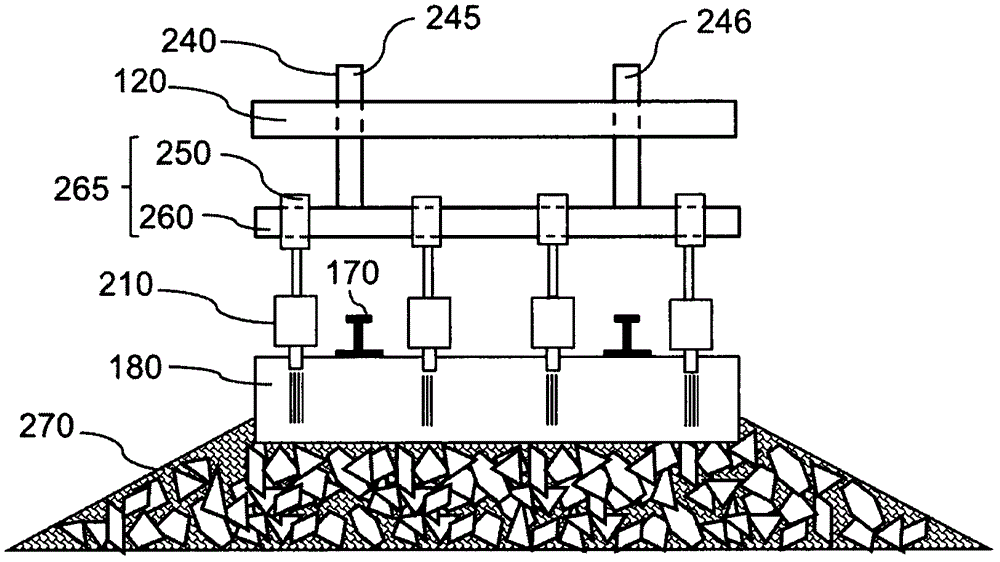

[0018] figure 1 is a side view of a pouring and foaming vehicle 100 according to an embodiment of the present invention, image 3 It is a front view with some parts omitted.

[0019] Such as image 3 As shown, the sleeper 180 is laid on the ballast bed 270 , and the steel rail 170 is supported on the sleeper 180 . The track bed 270, the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com