A kind of solvent-assisted fire flooding gravity drainage recovery method of oil reservoir

A technology for gravity drainage and heavy oil reservoirs, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc. It can solve the problems of high oil layer resistance, fire escape, hidden safety hazards, etc., and achieve the expansion of the combustion surface and the flow The effect of high capacity and low flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This embodiment provides a method for recovering a heavy oil reservoir by solvent-assisted fire flooding gravity drainage. The main oil layer of this heavy oil reservoir is buried shallowly, with an average buried depth of 450m, an original reservoir pressure of 4.2MPa, and an original reservoir temperature of 26°C; the viscosity of crude oil is high, the viscosity of degassed crude oil at the reservoir temperature is 1 million centipoise, and the effective average thickness of the reservoir is 15m.

[0054] The solvent-assisted fire flooding gravity drainage recovery method for heavy oil reservoirs provided in this embodiment includes the following specific steps:

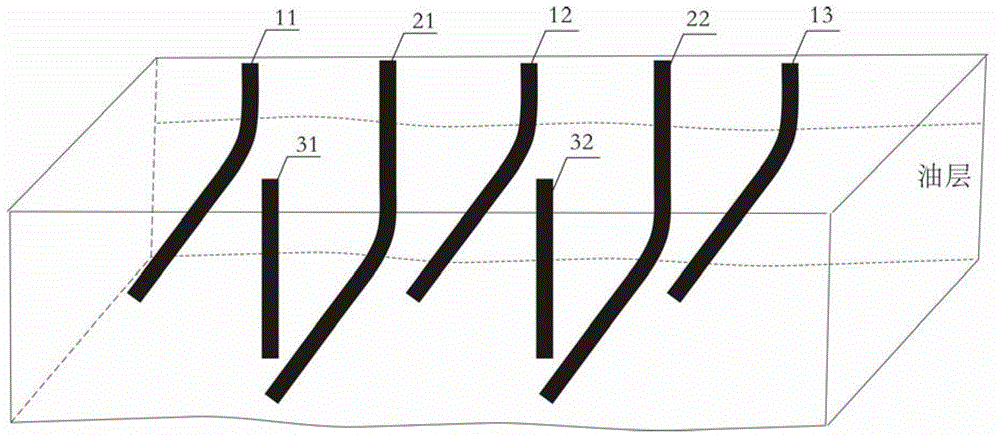

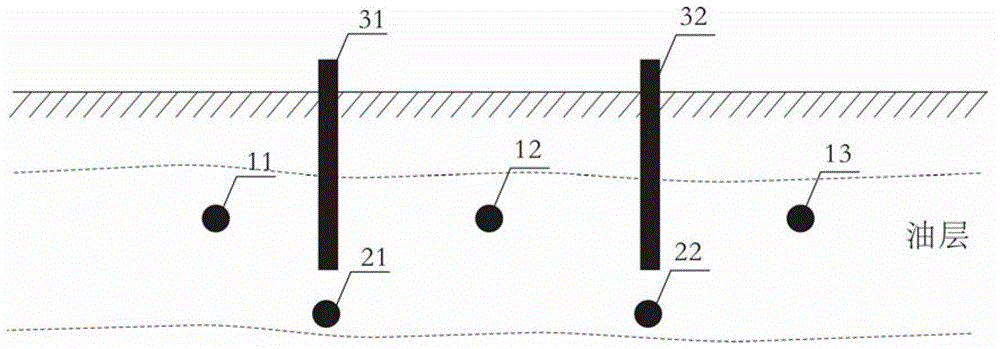

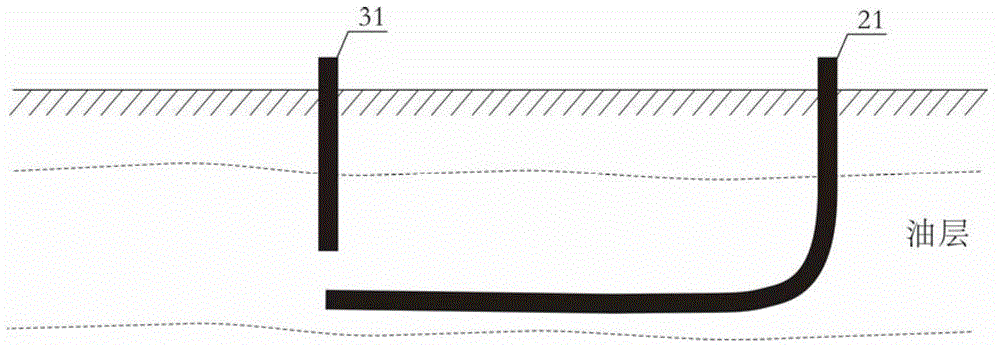

[0055] (1) First, two pairs of adjacent horizontal production wells and vertical injection well injection-production well patterns are set in the production area of the heavy oil reservoir. Specifically, one horizontal production well and one vertical Injection wells form an injection-production well grou...

Embodiment 2

[0071] This embodiment provides a method for recovering a heavy oil reservoir by solvent-assisted fire flooding gravity drainage. The average buried depth of the main oil layer of the heavy oil reservoir is 400m, the original reservoir pressure is 3.7MPa, and the original reservoir temperature is 23°C; The viscosity of degassed crude oil at the reservoir temperature is 10,000 centipoise, and the effective average thickness of the reservoir is 30m.

[0072] The solvent-assisted fire flooding gravity drainage recovery method for heavy oil reservoirs provided in this embodiment includes the following specific steps:

[0073] (1) First, two pairs of adjacent horizontal production wells and vertical injection well injection-production well patterns are set in the production area of the heavy oil reservoir. Specifically, one horizontal production well and one vertical Injection wells form an injection-production well group; preferably, the lateral distance of the horizontal sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com