Valve plate of feed bin discharge valve

A technology of unloading valve and valve plate, which is applied in the field of valve spare parts, can solve the problems of easily damaged silo, reduce the service life of the machine, waste manpower, etc., and achieve the effects of low manufacturing cost, increased service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described below in conjunction with accompanying drawing.

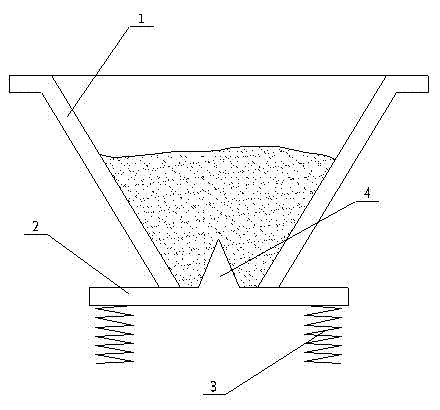

[0012] attached figure 1 It is a valve plate of a silo discharge valve according to the present invention, including a valve plate 2 fixed inside the valve body (not shown in the figure); the valve plate 2 is located at the bottom of the silo 1, and the valve plate 2 Fixed in the valve body by a spring 3; the valve plate 2 is located at the center of the bin 1 and is provided with a conical projection 4; the cone angle of the conical projection 4 is 24°; the conical The height of the bump 4 is at least 1 / 6 of the height of the feed bin 1 .

[0013] Due to the application of the above-mentioned technical solution, the present invention has the following advantages compared with the prior art:

[0014] The valve plate of the silo discharge valve of the present invention can automatically solve the material blocking phenomenon in the silo without shaking the silo, has simple structure, l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com